None taken Plasma56... actually I wasn't really focusing on your grammar or spelling at all... I was merely disappointed that the publisher of that paper didn't proof read it better if at all then again because of the author's origin, more than likely it was a language issue -that's all... heck, even I make spelling mistakes on occasion as well as grammatical errors from time to time so I'm the last one being overly critical regarding another persons spelling and use of grammar unless that is, when the individual is a chronic repeat offender and only with the intent of educating and/or enlightening the individual...

Overall, yes I do agree that basically speaking we are on the same page... I believe the issue is the method of delivery as well as describing - elaborating of various points involved is where we are different to say the least yet, it's for the most part refreshing to witness the proofs of individuality in action if you will - in this here forum... So yes indeed no hard feelings at all...

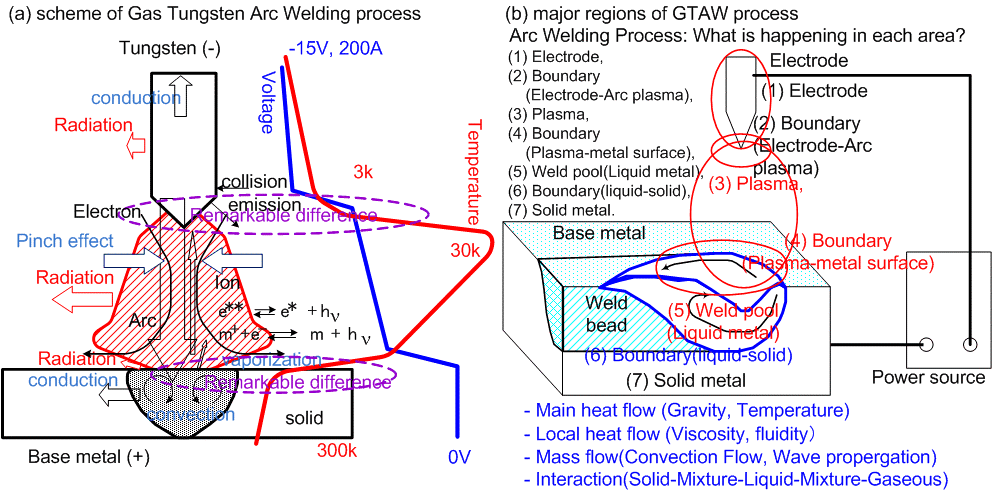

And while we're still thinking about GTAW, here is some interesting information in the form of articles, and manual(s) from Miller Electric covering the fundamentals of GTAW...

This .pdf describes GTAW and offer guidelines to weld with an inverter type power source... A large portion cover AC welding of Aluminum yet, there's also coverage of DC current, differences in polarity, tungsten prep, HF basics with respect to various arc starting methods used also... A nice pamphlet to have when welding with an inverter type power source.

http://www.greatnorthernprepper.com/wp-content/uploads/2013/01/Guidelines-for-Gas-Tungsten-Arc-Welding-2008.pdfHere's a version of the Miller Guidelines booklet that was a German manual translated to English? At least that's how the booklet is described.

http://www.germanmanuals.com/images/TIGBook.pdf

http://www.germanmanuals.com/images/TIGBook.pdfHere's another guide that is informative as well:

http://www.techtrain123.com/publicdownloadsallfiles/GAS%20TUNGSTEN%20ARC%20WELDING.pdfWith regards to Base Metal Temperature in Gas Tungsten Arc Welding, here's an interesting article: Elimination of interfering radiation from the arc and tungsten electrode

are found to be required for accurate infrared temperature measurements of base metal temperature:

http://www.aws.org/wj/supplement/Farson/farson.html "To strike the welding arc, a high frequency generator (similar to a Tesla coil) provides an electric spark; this spark is a conductive path for the welding current through the shielding gas and allows the arc to be initiated while the electrode and the workpiece are separated, typically about 1.5–3 mm (0.06–0.12 in) apart. The electric arc produced can reach temperatures of at least 5000° C. This high voltage, high frequency burst can be damaging to some vehicle electrical systems and electronics, because induced voltages on vehicle wiring can also cause small conductive sparks in the vehicle wiring or within semiconductor packaging. Vehicle 12V power may conduct across these ionized paths, driven by the high-current 12V vehicle battery. These currents can be sufficiently destructive as to disable the vehicle; thus the warning to disconnect the vehicle battery power from both +12 and ground before using welding equipment on vehicles." Jeffus 2002, p. 378 & Lincoln Electric 1994, p. 9.4–7.

A patent on a new type of HF assisted arc initiation.. "Arc welding with synchronized high frequency assist arc initiation." :

http://www.google.com/patents/WO2014135964A2?cl=enWell, Toey did ask me and probably other folks in here as well to mentor him regarding the wide range of topics that make up various factors and aspects regarding GTAW...

So in this regard, I aim to please!

Modelling of fundamental Phenomena in Welds.:

http://www.osti.gov/scitech/servlets/purl/10178263Exploring Infrared Sensoring for Real Time Welding Defects Monitoring in GTAW.:

http://www.ncbi.nlm.nih.gov/pmc/articles/PMC3247742/A Weld Defects Detection System Based on a Spectrometer.:

http://www.ncbi.nlm.nih.gov/pmc/articles/PMC3348795/Defect Detection in Arc-Welding Processes by Means of the Line-to-Continuum Method and Feature Selection.:

http://www.ncbi.nlm.nih.gov/pmc/articles/PMC3292081/Review of Arc Efficiency Values for Gas Tungsten Arc Welding.:

http://hv.diva-portal.org/smash/get/diva2:523654/FULLTEXT01.pdfOptimization and Non-destructive Test Analysis of SS316L Weldments Using GTAW.:

http://www.scielo.br/pdf/mr/v17n1/aop_191413.pdfProgress Report on a Fully Automatic Gas Tungsten Arc Welding (GTAW) System Development.:

http://www.osti.gov/scitech/servlets/purl/10106005A comparison of the physics of Gas Tungsten Arc Welding (GTAW), Electron Beam Welding (EBW), and Laser Beam Welding (LBW).:

http://ntrs.nasa.gov/archive/nasa/casi.ntrs.nasa.gov/19860002006.pdf http://ntrs.nasa.gov/search.jsp?R=19860002006Gas tungsten arc welding in a microgravity environment: Work done on GAS payload G-169.:

http://ntrs.nasa.gov/archive/nasa/casi.ntrs.nasa.gov/19870010873.pdfElectrode carrying wire for GTAW welding,:

http://ntrs.nasa.gov/archive/nasa/casi.ntrs.nasa.gov/19900016852.pdfPatent for a GTAW Torch with a coaxial vision camera within the torch.:

http://ntrs.nasa.gov/archive/nasa/casi.ntrs.nasa.gov/20080008217.pdfGrain refinement control in TIG arc welding.:

http://ntrs.nasa.gov/archive/nasa/casi.ntrs.nasa.gov/19750011611.pdfStudy of Radiographic Linear Indications and Subsequent Microstructural Features in Gas Tungsten Arc Welds of Inconel 718.:

http://ntrs.nasa.gov/archive/nasa/casi.ntrs.nasa.gov/20080002286.pdfSurface Temperature Distribution of GTA Weld Pools on Thin-Plate 304 Stainless Steel.:

http://aws.perusion.com/wj/supplement/WJ_1995_11_s353.pdf Humping formation in high current GTA welding.:

https://www.ualberta.ca/~ccwj/publications/Papers/Conference/Humping/Mendez%20-%20Humping%20Formation%20in%20High%20Current%20GTA%20Welding.pdfINVESTIGATION OF FLOW DYNAMICS AND PLASTIC DEFORMATION IN ARC WELDING USING SPH.:

http://www.cfd.com.au/cfd_conf09/PDFs/124DAS.pdfDouble Stage Plasma Arc Pipe Welding Process.:

http://www.aws.org/wj/supplement/WJ_2012_12_s346.pdfWelding Science: A New Look at a Fundamental Technology.:

https://str.llnl.gov/str/November01/Elmer.htmlVisiting professor welds new partnerships.:

https://www.llnl.gov/news/aroundthelab/2014/Aug/ATL_0080814_baker.html Direct Observations of Austenite, Bainite and Martensite Formation During Arc Welding of 1045 Steel using Time Resolved X-Ray Diffraction.:

https://e-reports-ext.llnl.gov/pdf/305013.pdf Numerical Modeling of Enhanced Nitrogen Dissolution During Gas Tungsten Welding.:

https://e-reports-ext.llnl.gov/pdf/243973.pdfComparison Between Keyhole Weld Model and Laser Welding Experiments.:

https://e-reports-ext.llnl.gov/pdf/245608.pdfSynchrotron-Based Experimental Investigations and Numerical Modeling of the Kinetics of Phase Transformations in the Heat Affected Zone of Welds.:

https://e-reports-ext.llnl.gov/pdf/238810.pdfInfluence of Thermal Aging on the Mechanical and Corrosion Properties of C-22 Alloy Welds.:

https://e-reports-ext.llnl.gov/pdf/238610.pdfKeyhole TIG Welding Process.:

http://www.msm.cam.ac.uk/phase-trans/2004/CSIRO2/keyhole.htmlhttp://www.k-tig.com/how-it-works/http://www.k-tig.com/brochure/ There's more but, I have to fix a billing question for my cable TV service so I'll end it here.

Respectfully,

Henry

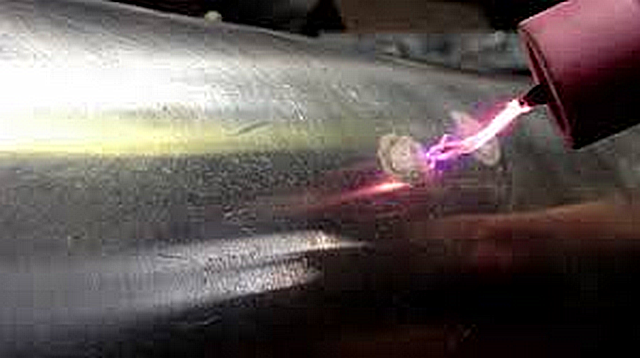

Although I do tend to lean towards Larry's explanation of what could have and/or what possibly did happen, and why as well including the intent/purpose of capturing the snapshot of the image in question and yet it's still only a very good probable explanation... Hmmmmm... Fascinating!

Although I do tend to lean towards Larry's explanation of what could have and/or what possibly did happen, and why as well including the intent/purpose of capturing the snapshot of the image in question and yet it's still only a very good probable explanation... Hmmmmm... Fascinating! ), and welding the shells to the heads with an automated circumferential welding system I designed from different brand name components which I initially objected to and yet, still made it work to as close to perfection as possible...

), and welding the shells to the heads with an automated circumferential welding system I designed from different brand name components which I initially objected to and yet, still made it work to as close to perfection as possible...