FC feild materials identification :

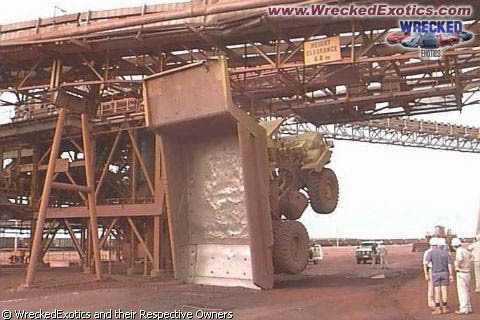

Steel ; anything heavy that rusts

Stainless ; anything heavy that doesnt rust

Aluminum ; anything light that doesnt rust

Thats it, theres olny 3 metals, anything else is some of that there fancy space age materials and has no place at all in the FC.

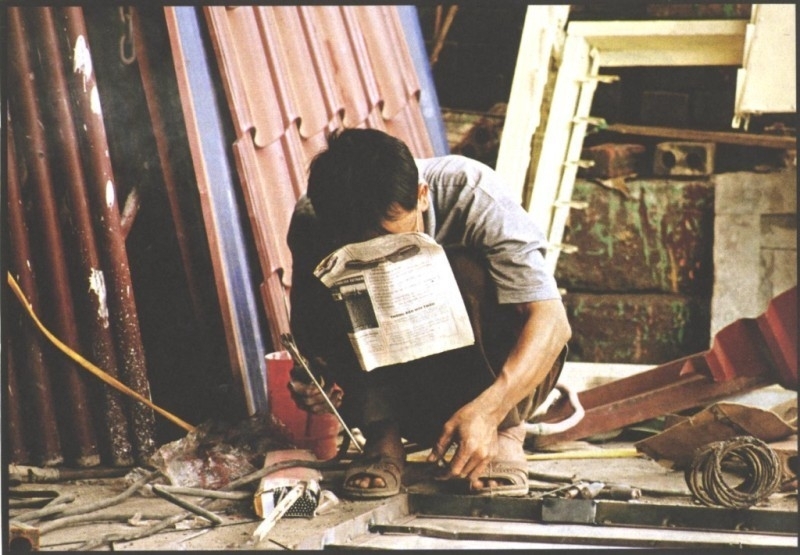

Steels can be properly welded with anything determined to be another steel, ex; coat hangers, fence wire, a thin strip of something that you hacked apart with a grinder...

there are no pre/post heat requirements and cleanliness is olny important if theres too much crap on the surface to strike an arc. Acceptable welds are covered in other sections.

Stainlesses are a special case and concist of anything thats heavy and doesnt rust and has nothing at all to do with cromeium or nikle, whatever they are...

Stainlesses are welded with a special rod known as 308, which is just the name for all stainlesses. all stainless jobs should be preheated to the point that they are glowing bright orange in strong sunlight. 1 rod works for all and whatever those silly profesionals are talking about diffrent grades and what not is a load of junk to get you to spend more money that you dont need to. If the 308 rod isnt available, a steel and a can of spray paint will have the same effect.

Aluminums are anything that looks like a stainless but is just too dang light to be a steel. These are special cases and can be easily handeled with that wonderious "alumiweld" rod. Aluminum is not weldable with a "steel" rod, but in some cases that mericle 308 rod will work, after all its a high tech wonder. aluminums need preheat as well, but they wolnt glow so the best way to tell is to touch it with your gloved finger. If the tip of the glove chars and shrivels, your ready to weld.

And remember, if all else fails, theres always duct tape. :)

-Clif