John,

"...I hope we didn't ruin your thread for you..."

with regard to even your statement, please let me add two more words on this interesting topic a bit more "seriously" (even though the biology of the Northern American fish species is fairly interesting as well).

The origination of fisheyes is quite interesting due to it is that specific.

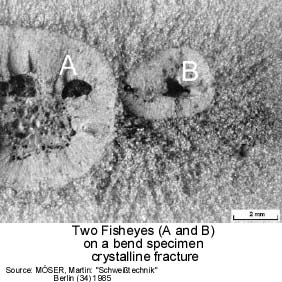

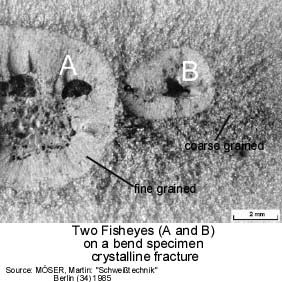

Normally one can't determine the hydrogen being responsible for even the "fisheye appearance" until the deformation or the fracture has occurred. Thus one might ask: "Where is the fisheye appearance originated actually?". As one can see in the jpeg I had attached three days ago, there is a difference with the fracture appearance between the "plain" fracture surface (rather coarse), see again the attached and "modified" picture, and the adjacent area around the "crack initiators".

While the cracking was initiated from even those "darkened" areas (quasi the pupil of the fisheye) which were pores from a cold lap (Area "A" in the picture) the hydrogen which was absorbed atomically prior to cracking is being actually "pumped" proportionally with the movement of dislocations along the {110} gliding planes. Finally the whole action results in an accumulation of dislocations saturated with molecular hydrogen. The fracture of those hydrogen saturated areas is even more "fine grained" and thus different to those areas which are showing a "regular" fracture surface appearance.

This however, just as a short addendum...

Best regards,

Stephan