Werner,

"Normally", PWHT would not include the heat treatment you describe, i.e., above the upper transformation temperature + tempering, rather something in the range of 1100-1200F for the purpose of relaxation of stresses, moderation of HAZ hardness, etc. Time of PWHT is qualified as 1.25x that of the PQR, e.g., 4 hours at temperature qualifies for 5 hours total time and temperature range and may be applied in one cycle.

Your PWHT is a true heat treatment and, although Section IX doesn't seem to address multiple cycles of such a heat treatment, I would think that each would stand on its own. It appears that you could perform the subsequent heat treat cycle, without requalification of the PQR.

My question would be, why are you performing such a PWHT procedure? What is your fabrication code that requires such action?

Cheers.

Fredspoppy, we are doing essentially the same thing. Our operation has to do with hot forming of plate into elbow sections... very, very thick elbow sections.

Fredspoppy,

Plug valves (API6D and API599/598) were repaired in "as cast" condition. Heat treatment for A352 LCC is quenching from above upper transformation temperature and tempering, so weld metal will be submitted to exactly the same.

Has ASME IX been revised to address time limits on PWHT?

Haven't seen an article in ASME IX on holding times (1,25 as mentioned above).

I'm using 2004 edition.

Welding process is GMAW, so only articles QW407.1, 407.2 and 407.4 are applicable for PWHT.

But the fundamental question stays there: is it allowable or not?

Per Section IX, its allowed. But I'm with Fredspoppy, that stress relief sure is high. Essentially ~50deg from transformation. If the carbon is at the upper end of the spec you could even be closer.

I guess to expand, each time you run a solution anneal you generally lose some tensile strength. It doesn't generally exactly return the matrerial to pristine condition. And then you toss a quite high stress relief on top of that. Nothing in and of itself wrong with that of course, but you will get a very fast response.

Now the good news is, in my opinion, that even if you are sitting just under the spec min for tensile strength, this is not a recommendaiton on my part, you will still be approximately, at least 4X the allowable stress for service. The other thing is, most of the stress relief response take place early. the second hour doesn't yield as much as the first and the third not as much as the fourth, etc. You get a diminishing response.

Thought maybe a general PWHT discussion might contribute something.

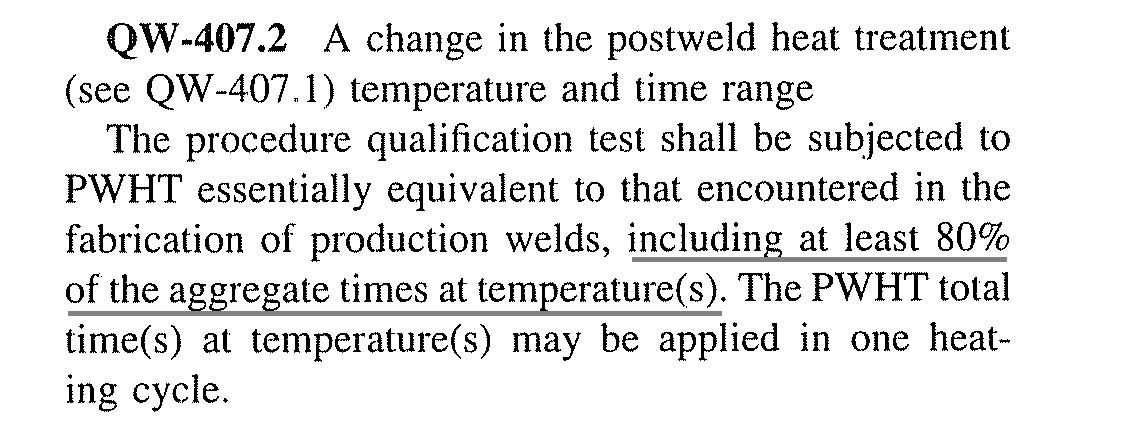

Here is the applicable paragraph. Actually says the PWHT shall be 80% of the time seen in production, i.e., 4 hour PWHT during WPQ qualifies for 5 hours of PWHT in production. Ends up 1.25 x that done during WPQ.

Fredspoppy,

But is this an essential variable. The text of the variables includes all of them. You have to go to the tables to determine if its essential, non essential or supplementary essential.

JS55 is correct in that the 80% of time requirement is a supplemental essential variable. However, what I missed the first time, and hasn't been mentioned up to this point is that LCC base metal has CVN requirements at -50F, so the WPS should be qualified with such as well. So the PQR has to have at least 80% of the casting cumulative PWHT time, but it can be in one cycle.

I believe that you are OK with one cycle per Section IX. Unless you do CVN tests, the only variable is the type of heat treatment. Not the time or number of times. As long as your filler metal can meet the tensile strength after Q&T PWHT, doing additional cycles generally only helps the properties as each cycle helps refine the grains.

The main problem with Q&T PWHT for carbon steel filler metals is that they can be low on strength after a PWHT above the upper transformation temperature due to their low carbon content. Even quenching after normalizing is a slow cooling rate compared to the original weld process. So hopefully you can work around that problem. I haven't tried GMAW, but have previously done SMAW and FCAW. SMAW is a little easier, but with care I was able to get the FCAW through as well.

Another thing to watch is the thickness. As compared to normal PWHT situations, you are only qualified to 1.1 times the thickness of the test plate. So the test plate thickness can go up very fast if you are welding on thick parts of the casting.