Hello everyone, I teach pattern development in one of my classes and am always looking for ways to help students to understand and visualize patterns and their developement better. Here are a few pictures of some classroom aids that I use. Would welcome other ideas, pictures, and thoughts from you out there.

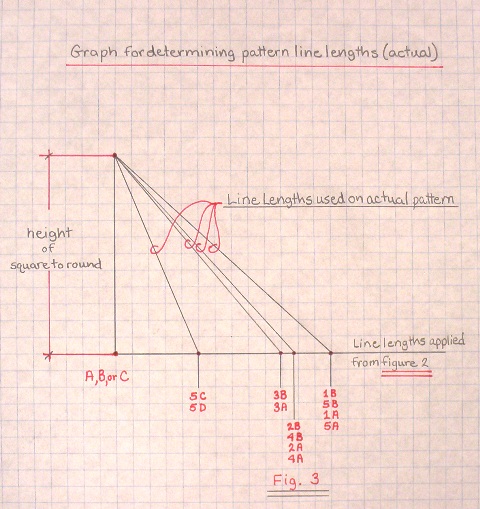

The picture with the dissected cylinder and plate also has triangles, of which the hypotenuse of those triangles represents the tru-length lines used for developing the square-to-rectangle that the example represents. The pictures of the other square-to-rectangle uses the wire pieces to represent pattern dimensions and lines. Best regards, Allan

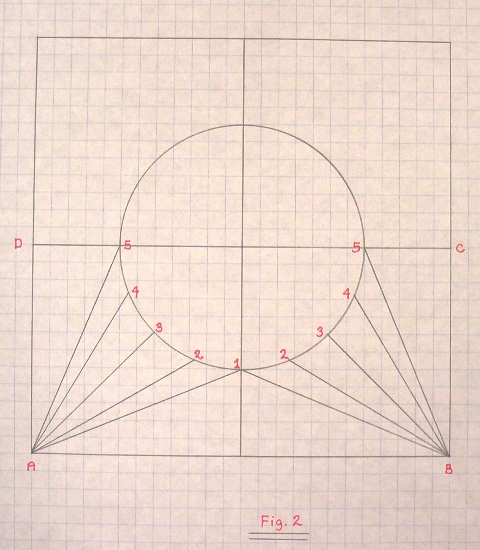

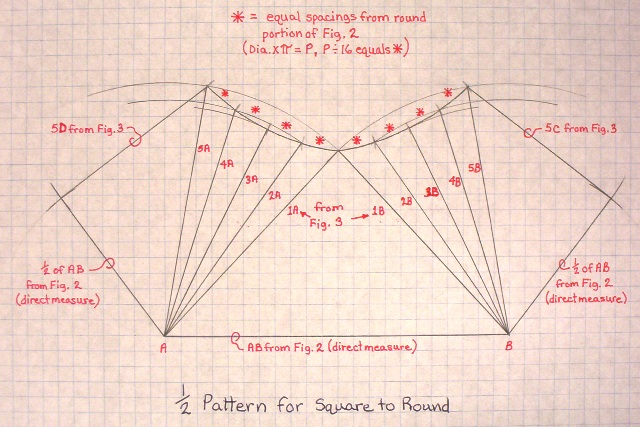

Aeveld, what an execllent way, to show your students and journeyman alike what they are trying to accomplish by visualizing how the tru-lengths are physically accomplished in the triangulation method, and showing how the equal spacing works. Remember the shortest distance between two points is a straight line and by using a set of dividers to mark off the equal spacing from point to point you loose arc length at each spacing, especially if you don't use enough equal spacing. I calculate the equal spacing by (Diameter x 3.1416 divided by the number of equal spaces (12 minimum) and set my dividers to that so I don't loose circumference. It's really good to see people like you that really know their stuff sharing thier knowledge. I grew up in the custom sheet metal trade (43 years) and knowbody wanted to share anything they knew, but it just forced me to compete and learn on my own, which actually turned out to be the best thing that could have happened. RGL the L.O. calculator guy.

Thanks, RGL. By chance did you receive the private message that I sent you the other day? I made an inquiry through the forum about your calculator via private message. Best regards, Allan

That's pretty cool, Allan. A whole lot better than the way I learned it in the 9th grade.

I like that, when I was teaching topside welding I had some visuals that I had put together, but none like that. Mine was mainly laying out saddles and ells at different angles than was commerically available. That and I had come up with a down and dirty way of figuring the layout with just a wrap a round and a tape that I would show the students.

But I really like the way that you have that layed out.

Charles Welch

Thanks Charles, I do have some other types of layout aids that I will try to put on here in the coming days or weeks. I also hope that others might take the hint and post alternatives that I can share with my students and others. More choices and alternatives provide better suited methods for different individual learning styles. Best regards, Allan

I just wish that I had taken pictures of the aids that I had around the shop. When we moved from New Iberia to Carlyss, someone scrapped all the things I had for training personnel that I and others had come up with. I'll have to look in some of the notebooks that I have when I get back home to see if I have any drawings. If I do I'll be sure to post.

Charles Welch

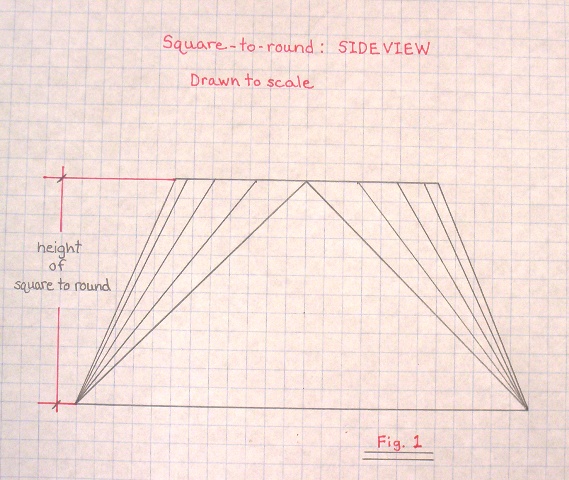

Hello again folks, I had hoped to expand a bit more on this topic. I've included a few more items for you to look at. These are examples of the simplest form of a square to round. There are only about 7 different measurements represented in this pattern,. If it had been an offset of some sort it would have been a lot more complicated and required different dimensions for each of the different quadrants, but would still have been approached in a similar fashion. Also, since this is a symetrical transition it doesn't require any particular attention to how it is laid out since it can be formed from either side of the layout without causing a problem with finished part. Transitions that have offsets in them require close attention to how the layout marks are included so that the correct hand of the part is realized upon completion. Those of you who might be making these types of shapes from something other than sheetmetal need to include centerline dimensioning for the round part and ID dimensioning allowances for the square end to have the shape come out according to your called out sizes. Entertaining comments for different methods, and criticisms welcome. Best regards, Allan