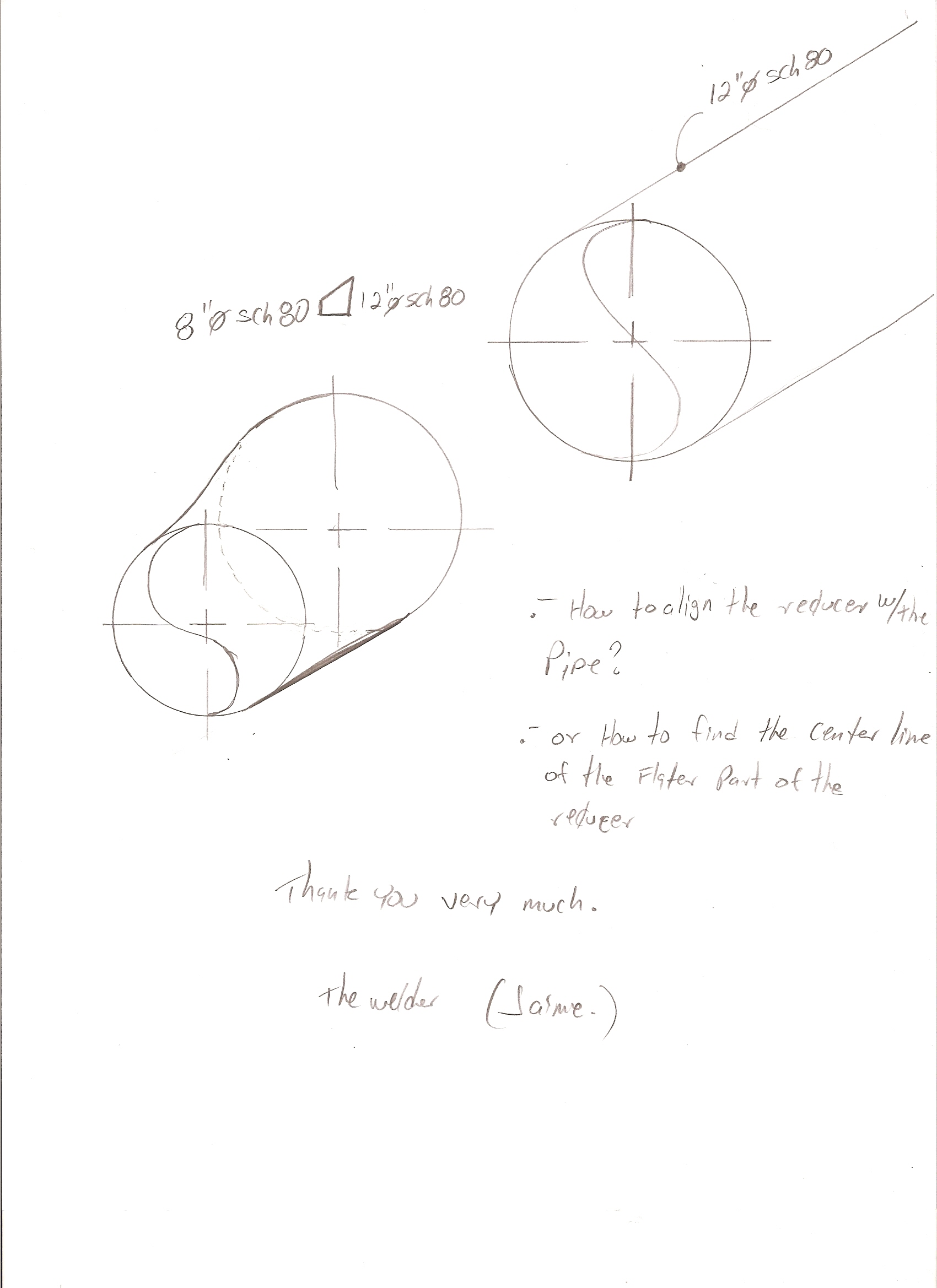

HI, do you check the other sketch? wath I try to do is, how to faind the center line on the flat part of the reducer?, went I do the prefab on the shop. no on the field because on the field, I can put fitting by fitting w/ no problem but on the shop the all assambly is upside down or side ways. thas way I need to faind a method to faind the center line on the flat part.

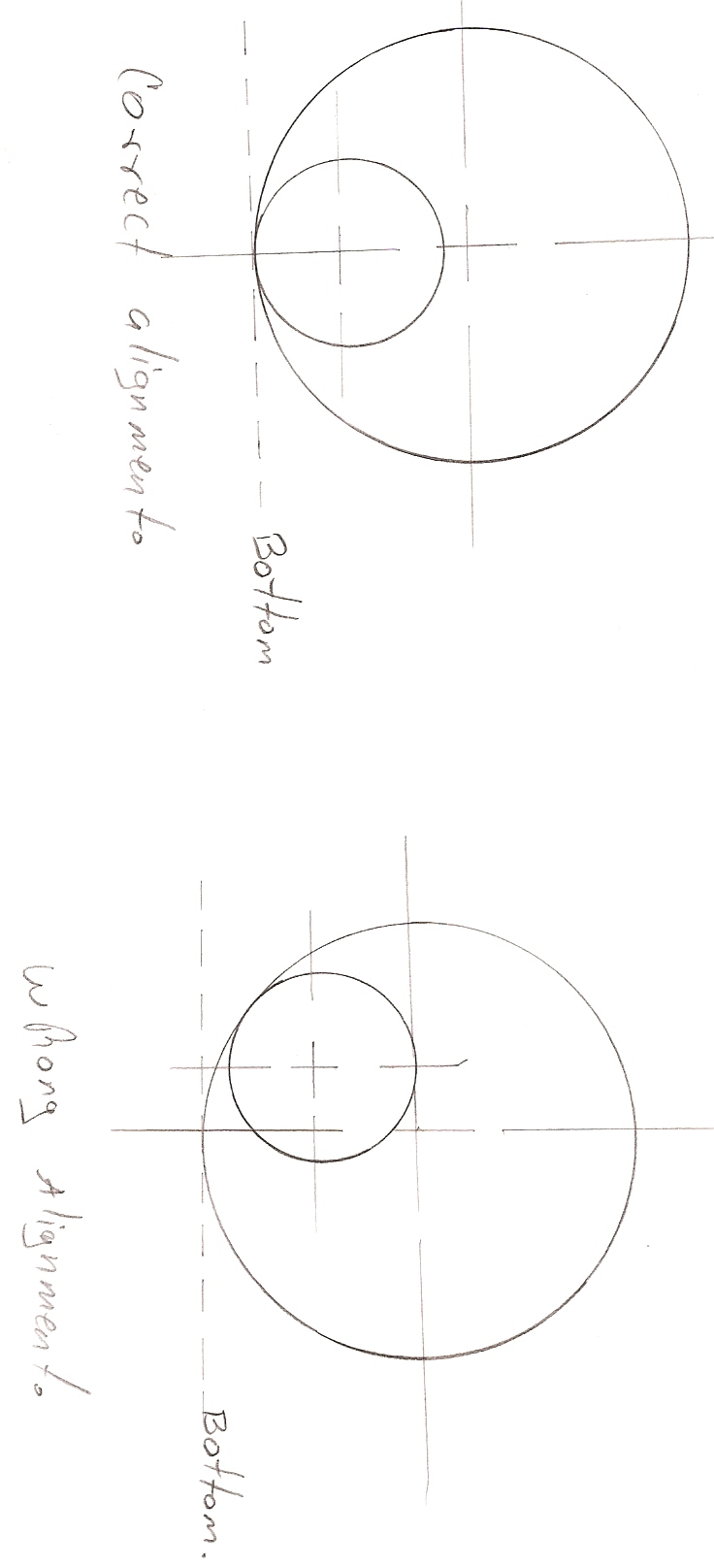

In the field, easiest method I've found is to tack up the ecc. red. ( two small tacks are sufficient) to a long piece of 8" (or the smaller size pipe, whatever). Fit it up "perfectly" with zero Hi-Lo, square and true to the run. Set this low on a pair of roller head (if available) jacks or horses with the flat on bottom. Now take two more jack stands pull the heads and extend the sleeves out and place on either side of the large end of ecc. red., rock it back an forth till it looks good. This is usually enough visual reference to "eyeball it in and then center punch TDC. For more accuracy, table top method works the best (flat concrete slab, etc.).... Draw a long line then lay out your 8" & 12" eccentric circles ( O.D. 8 5/8" and 12 3/4" ) on that center line. On the 12" circle, lay out 90 degrees and extend out past the circle. Center the fitting with small side down as close as possible to the layout. Take a combination square and slide the blade out until the blade end will set flat on the table ( I just thought about it and a large triangle rafter/framers square would work just as well) and set it on the 90 lines until the top end of the blade touches the fitting, see how far off the 12" circle it is and adjust accordingly. After it's fine tuned in, then you have the zero and 180 marks to transfer onto the small end. Make sure though that the small end stays true on the circle and this will be as close as the real world of pipe fighting needs to get. Hope this makes sense?????????????????????