Hello Dave, I teach at a community college. I don't envy the folks who are teaching at highschools, many times they seem to be the dumping grounds for many of the students that aren't viewed as able to be successful in the academic world or tend to have behavioral problems, in some instances this truly is the case, in others it is what the students themselves are encouraged to believe simply because others in the high school system aren't willing to help out or follow through or offer the necessary encouragement. Also, many of them take the vocational classes in high school because they figure it is an easy grade. I don't mean to say this is always the case, but often it is. High school programs are also made up of a captive group in a lot of instances, the students are told that they will be taking these classes and they don't have a choice, so many times they don't take advantage of the opportunity,realize the value of it at the time, or don't have a true interest.

For the most part my students are there because they want to be, in a few cases there are individuals that are there because they have found a way to work the system and really don't have a genuinine interest in being successful or it is the only way to continue to receive living assistance since the schooling is a requirement of the total aid package. Fortunately this isn't the norm. In yet other instances the students might start out without the drive, but after being there a while they come to appreciate what their education can bring to them so they buckle down and put in the effort and go on to be successful. I also have the benefit of a diverse grouping of students, at times I have had students as young as 13, the oldest probably in the high 80's, these age differences bring all sorts of different dynamics into the shop, having women and men together as well adds many different facets to the mix. The young tend to learn from the old, the older tend to show more enthusiasm as a result of having the younger ones to take on for mentoring. I get paid to sit back and referee and do a bit of guiding and skill building, I feel very fortunate to see all of the positive results. I could really go on for quite a bit of time discussing this, teaching for the sake of teaching is a great job, sometimes I get a bit discouraged with the politics of it, but then I get to share a moment of success with a present or past student and it makes it all worthwhile. Thank you Dave, I have enjoyed the many contributions that you bring to the forum and your positive outlook on life. Best regards, Allan

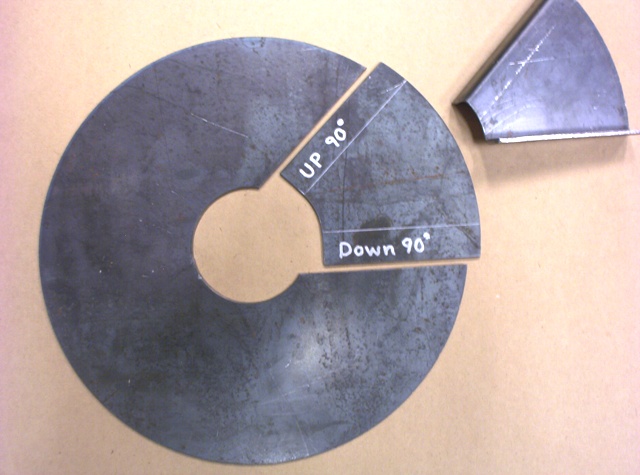

Allan, you are the MAN!!!! Way cool stuff!!!! I sure wish you would have been MY instructor when I was learning welding! Great stuff, teaching kids layout as well! Very cool!

Nice, very nice!

Best regards - Al

Hello Allan, thanks for the great pics and methods on the spiral staircase. I've never built one. I have installed a few large prefabbed spiral stairs in colleges and high schools and my hat goes off to anyone smart enough to design and build one.

With your diplomacy and intelligence I wish you were running for president :) I'd vote for you.

Hello Tim, thanks for the encouragement and compliments........ As to the presidency thing..... they couldn't pay me enough to take that one on!!!!!!!! Best regards, Allan