Not to try to confuse the topic even more,

but I always heard that the test is run as a 45 deg 6g, as you guys described, and the name "bell hole" refered to the type of environment the weld was typically performed in the field.

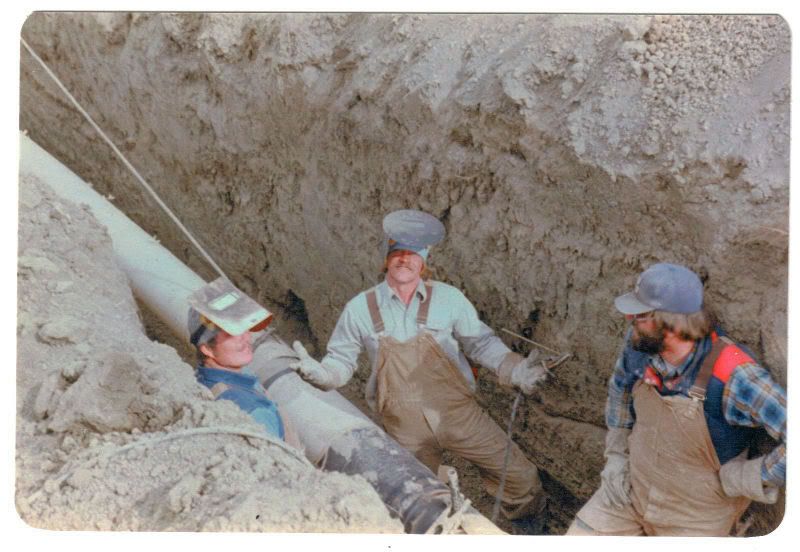

In other words, a bell hole is a hole dug in the ground around and under a buried pipe or gas main that requires the installation or repair of a "Wye" for tapping in an additional branch.

The test is to see if you can adequately weld these size pipes in position.

The trick is to perfrom the weld just as well as the test, after you get the job, and are standing in a hole in the ground, up to your knees in ice slushy mud.

An "Arkansas Bell Hole" is a hole in the ground, on the side of a hill, so the pipe is sloped.

I understand this is a very tricky operation when hot tapping into a live gas main, because if you blow through, you have to keep your head and fill in the hole by buttering the edges, without allowing the gas to catch fire....

I guess that would be called a smoking bell hole?

Anyway, that's how I've heard it...

Tim