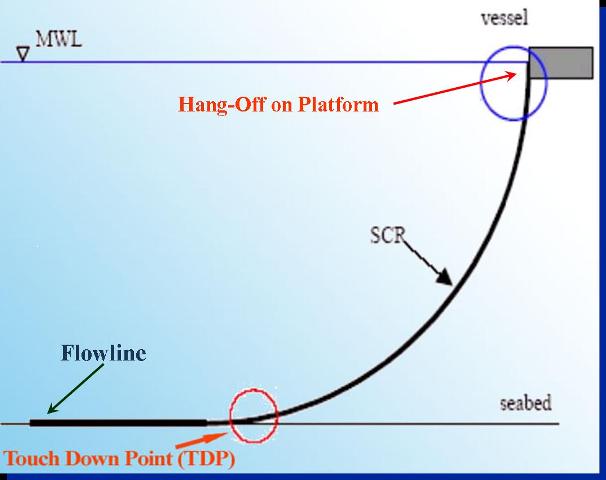

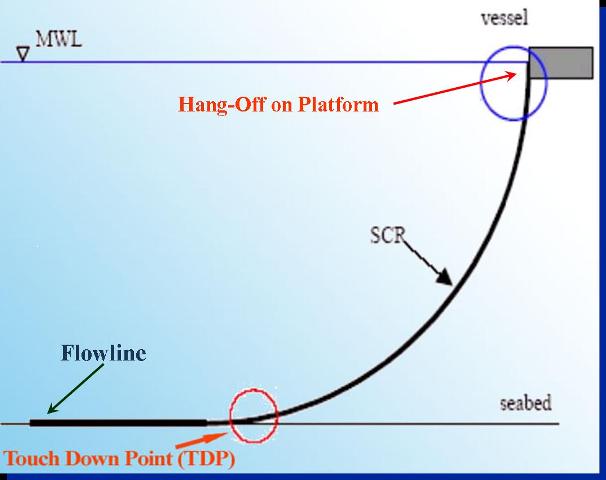

Related to the offshore Oil & Gas industry, a "flowline" is the term for the portion of the pipeline, laying on the bottom of the ocean, that connects the wellhead, and associated subsea equipment, with the platform. The portion of the pipeline that rises up from the bottom of the ocean to the platform is called the "riser". The point where the pipeline leaves the bottom to go up to the platform is called the "touch down point". It is really some length of pipe, due to tidal and wave effects that cause the platform to move up and down.

The important difference between flowline, touchdown and riser is the required level of quality for the pipelines and welds connecting the individual joints. As the riser is hanging from the platform, it is subject to more dynamic actions and therefore weld quality requirements are higher. Likewise the pipe in the touchdown area is also subjected to dynamic actions. The platform may be in water depths of up to 10,000 feet (~2 miles).

Attached is a sketch for your info. I am not sure if this relates to your specific situation, but should be of interest.