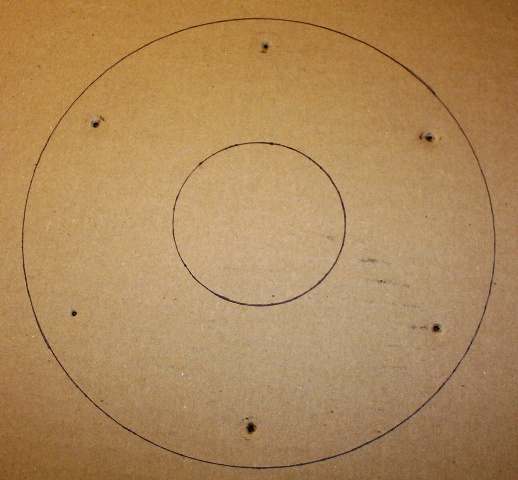

Hello everyone, a few topics back one of the other fellas made mention of transfer punches, unfortunately my shorttimers memory didn't allow me to remember who. Anyhow, here are a few pictures of how you can use them and what they are if you don't know. When you already have an item that has the holes layed out and you don't want to do the layout over and over there are alternatives, the transfer punches being one of them. In the example I traced around "the part" and then used the punches to locate the holes. In this example I also included a little trick that can be used if you don't quite have the correct size. The first holes were of a size that the punch fitted correctly, the second set of holes I "didn't" have the correct size so I wrapped the punch with electrical tape to enlarge it's diameter in order to fit the hole snugly.

One note of caution, transfer punches shouldn't be used to actually punch the material for hole locations, you should use a regular centerpunch to enlarge the punch marks for drilling or punching locations. They should be "lightly tapped" on enough to locate the point and then punched with a conventional punch afterwards. You will notice that the punches are flat on the ends except for a small point in the center of them, using too much force will smash or deform this point.

There are a host of uses for these: making covers for flanged openings, making a master flange and using it to lay out the rest of the flanges that have been made, tracing odd-shaped cut-outs and transferring the hole patterns from one to the other. Use your imagination for putting these to use for your particular situation. Best regards, Allan

Good tip Allen.

I will add one thing: It will help if you clamp the parts together using an 11R vise grip or even a C clamp. That way you will avoid the part shifting when you strike the transfer in the second or third hole.

We use this a lot when building machine bases or frames that have common pads on the feet, panel mounts, or top plate locators. We lay out the first plate with height gages or even on the mill and drill it, then one person can transfer everything while the other person in drilling holes.

Yes, I did forget to add that very important point. Thanks for noticing and including those very valuable instructions. Best regards, Allan

Tape looks like a good idea. We use a bushing driver set with different drivers from 1/2" to 1 3/8". Centers of the drivers will be one of two sizes that are found in the transfer punch set.

Hello warmka weld, that sounds like an excellent idea as well. I mainly included the tape idea for when you might be in a pinch and not have the right diameter to work with. Best regards, Allan

Yes, transfer punches have to be one of the handiest tools a person can own. I have gotten a lot of use out of mine thru the years & they do so much better a job than eyeballing the CL of a hole with a marker.

I think a guy of the most infinite of wisdom mentioned something about them awhile back! LOL :-)

S.W.

Hello Steve, I thought that it was possibly yourself, however, when I went over the previous posts I failed to notice where you had included it. Oh ONE Of Most Infinite Of Wisdom, or is that wisdumb?......Oops did I say that? I hope you know I'm just pulling your chain a bit! So please forgive me! Best regards, Allan

Allan, you are MOST welcome to pull my chain ANYTIME!!! :-)

Great demo. Made the point clear & easily. A lot of guys I have seen never even knew what these were. My good friend turned me on to them years ago. I went out & bought a set of them & later a bigger set. I can't say how many times they have come in handy for a layout job.

Another great demo Allan!! S.W.

Allan,

I have used tape several times on transfer punches and I have always met tolerance limits. It is a very effective way to make 3/16 work for 1/4. :-)

John

Disclaimer: Common sense MUST be applied.

Hello again warmka weld, I do have a set of those drivers that you mentioned. I'll try to find them and include some pictures of your example on here as well. Best regards, Allan

Hello again warmka weld, I managed to find my "cheapo" set of bushing drivers so here's my interpretation of what you were describing. Great idea and as you said it only requires a couple of sizes of transfer punches and the bushings can cover the rest of a number of different diameters/sizes. So here's the pics. Best regards, Allan

Thats what i was talking about,seems to work good. The tape like most of your ideas is one of those why didnt i think of that ideas. Any chance to learn a shortcut or easier way is good to me! Keep them comin!

Some aditional uses:

To trace a part larger than the sample [to allow for machining or a torch kerf] a transfer punch maintains the ofset while tracing iregular shaped parts.

To locate bolt holes a specific distance in from edges, a bushing or an ironworker die, washer or similar can be lined up with the part's edges and the transfer punch used to mark the hole's center. This is handy for 1 off parts where the mating holes will be located with transfer punches, saves layout time.

Hello Dave, those are terrific additional uses for these tools. Are you referring to using the transfer punch as a sort of "scribe" and due to it's diameter it marks an even amount of oversize? Hadn't even considered that, great idea. Thanks and best regards, Allan

Allan, Yes, You understand corectly.

In addition to transfer punches, there are transfer screws. These allow blind drilled tapped bolt holes to be marked. These screws come in 2 types, one resembles a set screw with a point, the other resembles a short bolt with a point and a concentric circle raised around it on the head.

To use these, they are screwed into the tapped part, in the case of the setscrew type with the points all protruding equally. The part is set in place and tapped with a lead or copper mallet to mark the surface with the points.

As with transfer punches, the initial punch marks will need to be enlarged with a center punch.

Hello Dave, I have seen the transfer screws, I believe you have somewhat described these as a machinist tool or tool and die-maker tool. I don't know of many fabricators who have these, although they could certainly be put to use in many instances. Thanks for the additional information and thoughts. Best regards, Allan

Yes, these are commonly used in machine building and tool and die making. I don't know of any low cost ones, but they are a life saver when You need them.