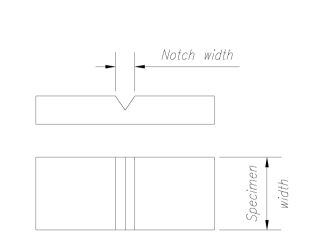

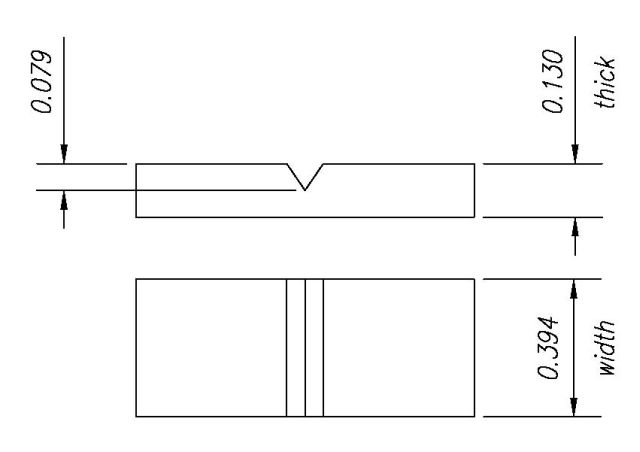

Because the notch has to be oriented normal to the material surface, the width across the notch essentially IS the thickness.

In your case the width across the notch is not the thickness and therefore is invalid per 31.3.

The reduction of thickness takes place on the surface perpendicular to the notched surface. In this way no matter how much you reduce the thickness of the specimen the thickness resisting the hammer on the charpy machine is the same.

On other words, you cannot have 1/4" thick material with a full width (3/8") notch and still comply with 31.3, unles you can somehow invoke the idea that the material does not allow such dimensions. If your testing on plate or pipe this will not be the case. Even on small diameter pipe the problem will not be the dimension of the surface perpendicluar to the notch, it will be the length of the specimen.

The diagram you have posted is, in my opinion, non compliant