I think what im hung up on is the 1t hole 2t hole and 4t hole.....

for example i have a pene i see the "3 sides"...........dose it matter what hole is visible in achieving 2% RQL(I KNOW I NEED TO SEE THE HOLE CALLED OUT IN THE SPEC OR CODE)It does not matter which hole, or even if you can't see any hole.....if you can see the edge(s) you have achieved 2% sensitivity.

My first shot....3 sides of the pene and hole 1T is visible, and my second shot 3 sides of the same pene and hole 2T is visible.

Do the above shots have different RQL? or does the shot with the 1T hole just have better definition.You still have 2% sensitivity on all shots, one has 1T resolution (2-1T quality level) and the other has 2T resolution (2-2T quality level)

~~~~~~~~~~~~~~~~~~~~~~~~~~~~~~~

Mike,

Hung up is a good term to use here because in effect, we are hung up on terms.....so, staying with our example(s) where we have been talking about 2% sensitivity....... Now chew on this, and hopefully this will make sense, if not I always enjoy these type of discussions, so we'll keep at it.

Various degrees of image quality can be measured by using a hole type pene.

Sensitivity is determined when the pene selected is a percentage of the material thickness being examined. If you can distinguish the difference in density, such as along one edge or more you have proved sensitivity. Likewise if you can also disguinish that same density difference around the edge of a hole, a square, a notch or a triangle shape cut out of the pene you have also proved sensitivity. In our example, this would prove 2% sensitivity.

Resolution is determined by the smallest hole size visible on the pene under examination.

(now the hole comes into play) Resolution is measured in terms of 1T, 2T or 4T. 1T represents a hole diameter equal to the thickness of the pene. 2T is a hole 2 times the thickness of the pene, and so on.

Image quality level or

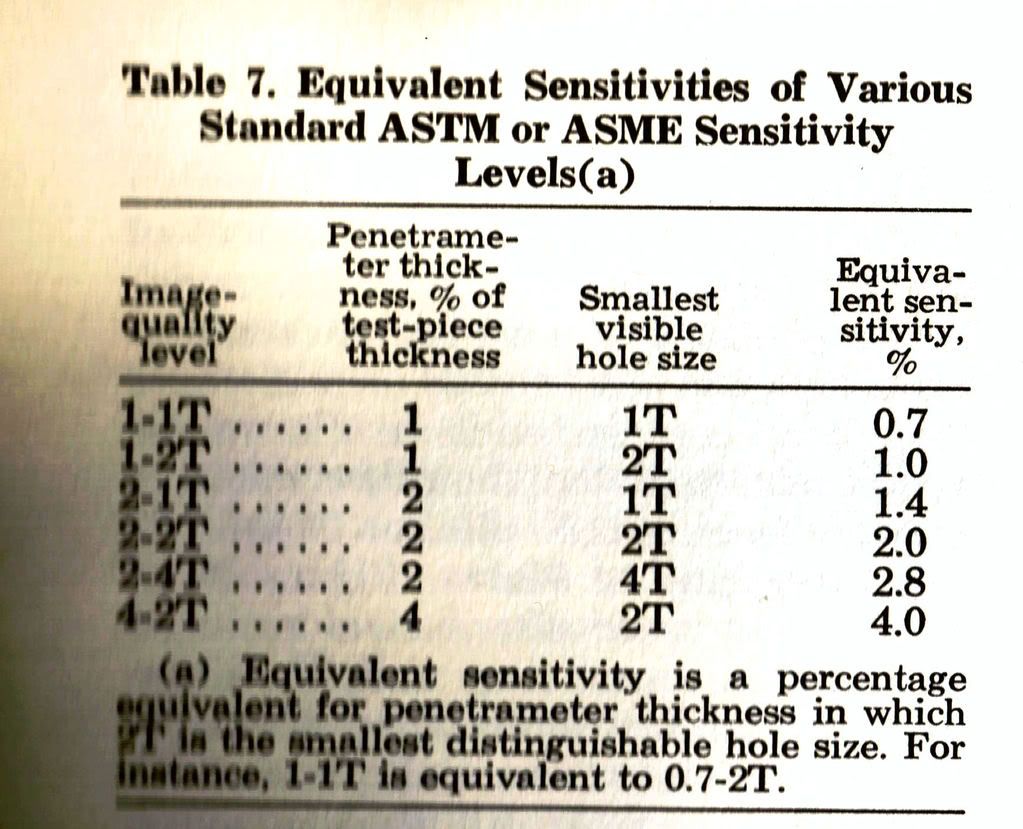

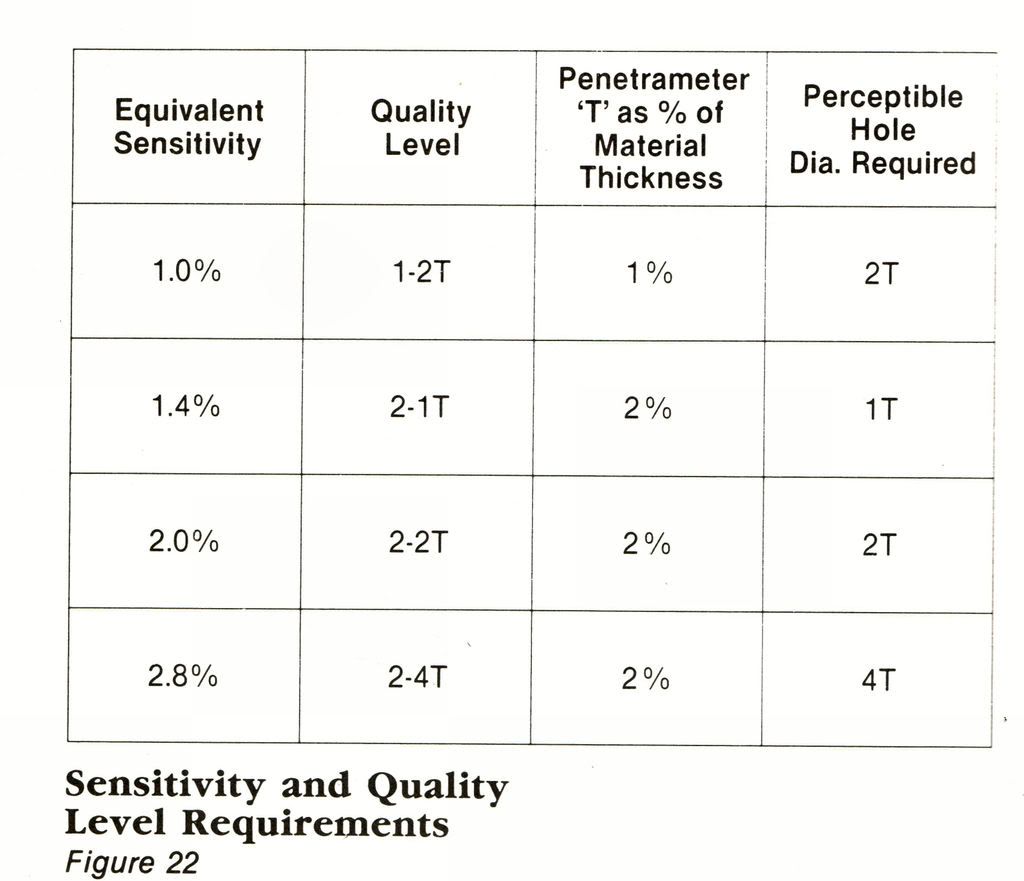

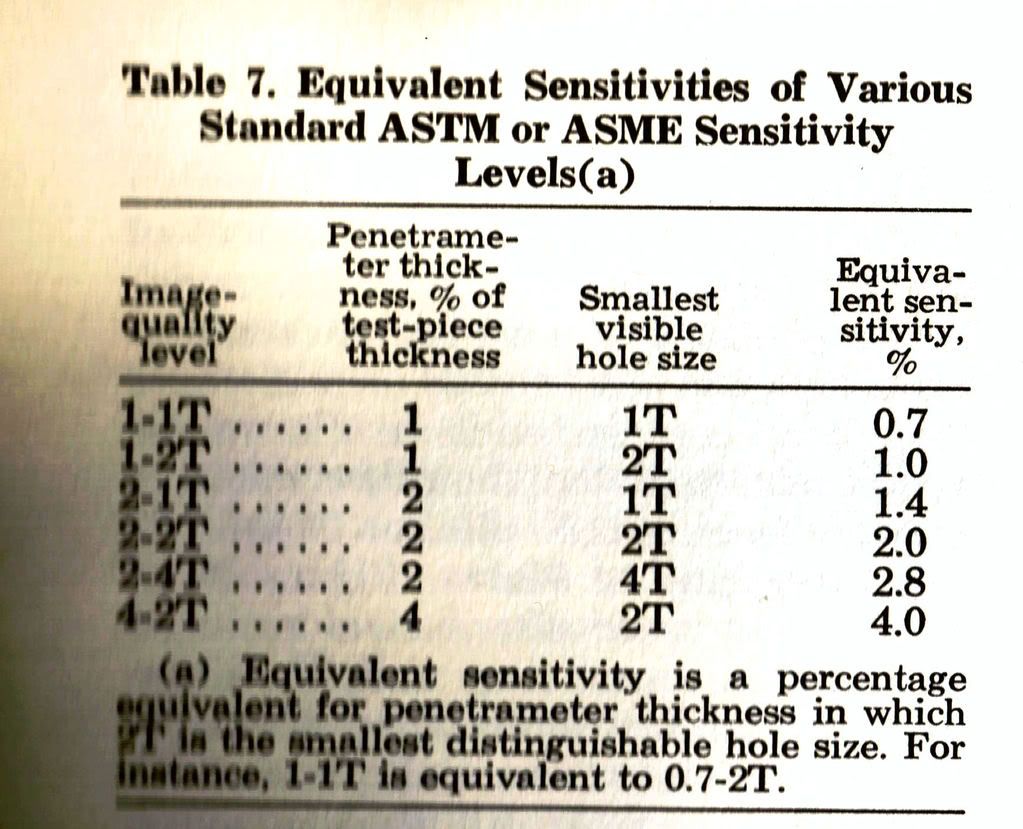

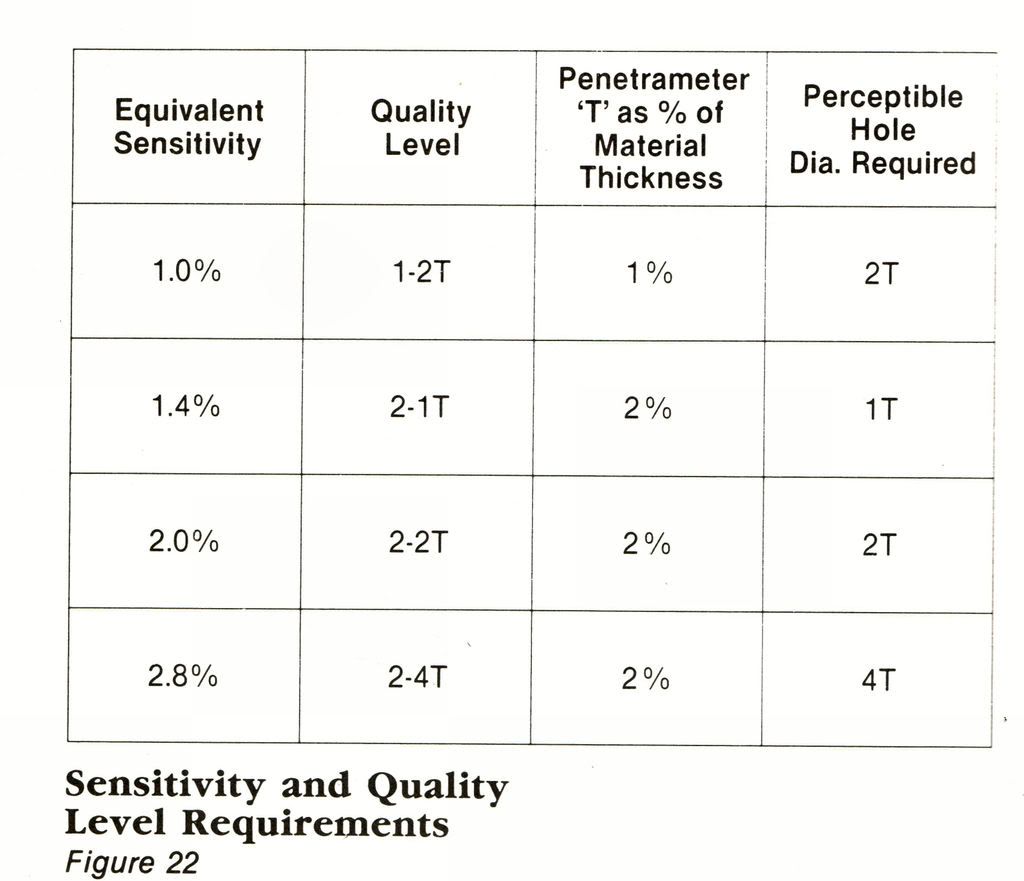

quality level are terms where both sensitivity and resolution are taken into consideration. Image quality levels are expressed as 1-1T, 1-2T, 2-1T, 2-2T and so on.

A Code of specification will state the image quality level that is required. This means both sensitivity and resolution must be achieved. Here are a couple of charts that show equivalent sensitivity levels when some of the variables change.

~thirdeye~