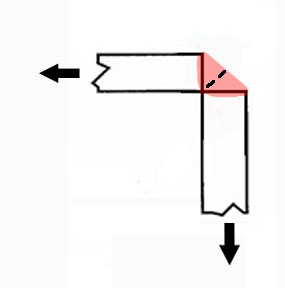

more day-dreaming... if the offset edge weld acts as a fillet weld, then the normal means of failure would be shear across the depth of the throat. However If a force is applied in the plane of the base material than the it would transmit through the weld at perpendicular to the weld throat. Would that affect how the weld fails and it's design strength?

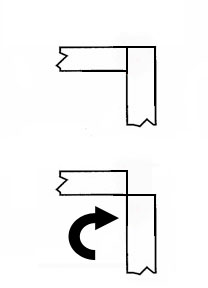

My somewhat uneducated mind would think first that the joint design selection would be based primarily on the material type and thickness, and then perhaps its potential application. The bottom sketch, for instance, would be completely acceptable for cosmetic sheet metal work. I prefer the joint design in the top sketch for anything structural, with a bevel in the horizontal member to aid penetration, and a fillet in the backside corner. Of course, with some materials, this might not be advisable, such as on heat treatable aluminum alloys, where you must carefully control heat input. Just my two pennies.