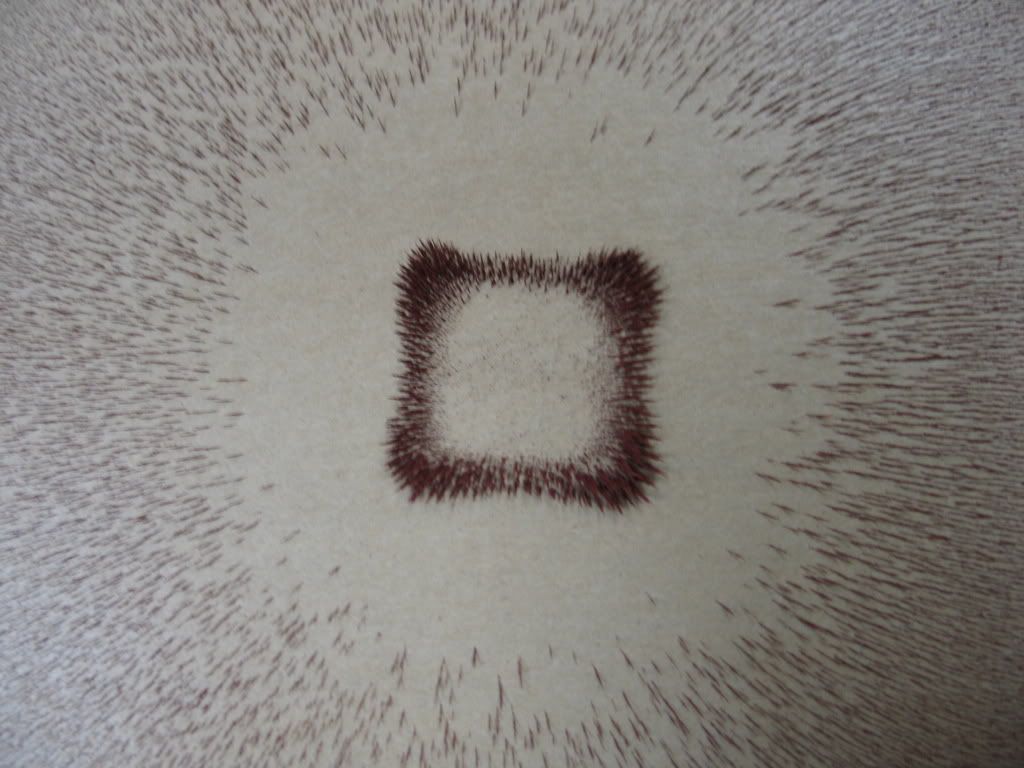

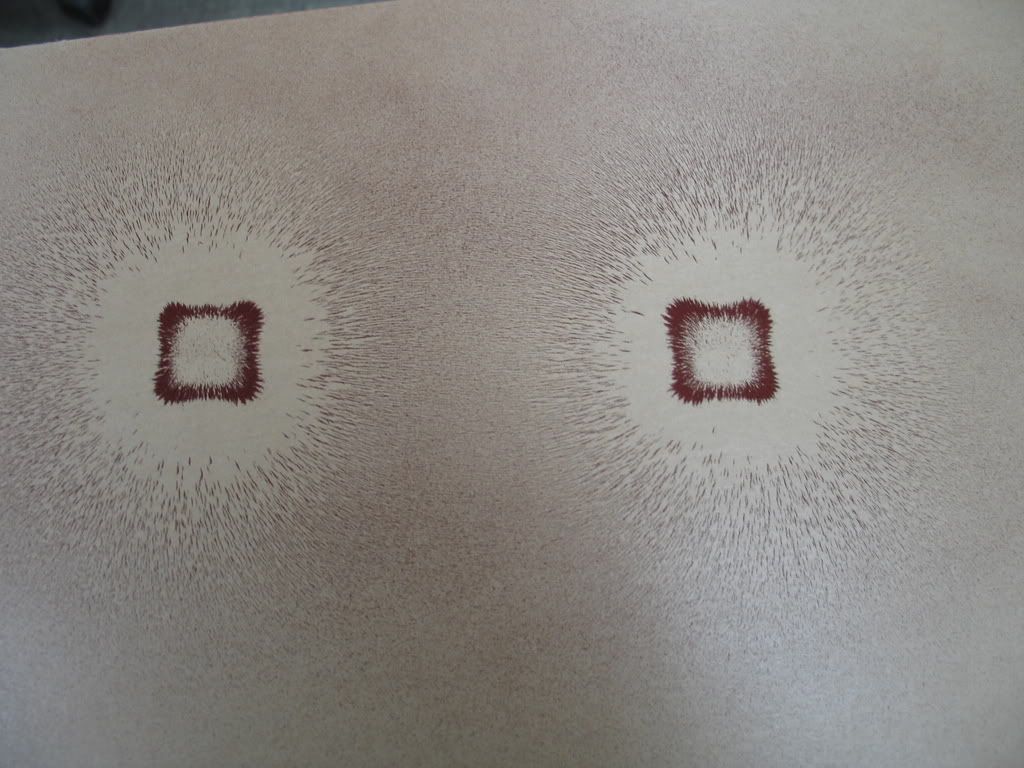

Nice images, John, thank you. No, i have no knowledge of why the filings are in that pattern. Your idea of "turbulence", or incoherence, is perhaps on the right track, the total field strength in the filing-free region should be so much weaker than in the adjacent regions (immediately around the pole piece and some distance removed from it) that it is not strong enough to prevent the adjacent stronger field from "robbing" it of its filings.

In practical terms I'll know now not to abut the poles close up to the area of interest but to keep them somewhat removed so that possible discontinuities will not get missed through lack of sufficient flux leakage in that area.

Your question is a tough one, and one that no hard fast rule to my knowledge has approached. However;

In Particle physics, a force carrier for the particles could be an electromagnetic force. Pauli "pauli exclusion principle" states that no two identical fermions (particles) can occupy the same quantum state simultaneously. (part of what I believe enforces the spacing between magnetic lines of force)

If this is true, then the quantum spin would be associated with angular momenta, but since it's also associated with electromagnetism for obvious reasons, the particle spin would also have to take into account wave particle duality (Maxwell/plank/Einstein etc)

The only way I've been able to find for that to come together is to use Werner Heisenberg's Uncertainty principle.

Getting to wave mechanics, there is constructive and destructive interference. Since the combined work of Pauli, Maxwell, Plank, Einstein, and to a degree faraday, and some others seem to share common ground in this regards, and that it's generally accepted scientific theory for electromagnetism to be both wave and particle, and that no known magnetic source has ever been found to be monopole, there would almost have to be both a superposition constructive interference point and just away from it a destructive interference point at or near the exits/entrances of the poles of a magnet and or electromagnet.

If this is the case, then every single magnetic source would exhibit the same signs of super positioning and destructive interference.

The earth exhibits such a sign, a bar magnet, and an electromagnet.

What that means to me in regards to your picture is, the points of collection directly over the legs where dust has collected would be the super positioned point of saturation with a destructive interference zone shortly thereafter, until the spin momenta stretched out and the wave form of the flux line connected in a pulsating manner with it's opposite pole. (the pulsation due to the negative / positive spin momenta depending on which specific line of force in question).

That's my opinion of why the picture is as it is for what it's worth. However; no one really knows for sure, and I've never seen anyone try to explain so I was left to my own devices. I may be wrong, but there it is.

Regards,

Gerald