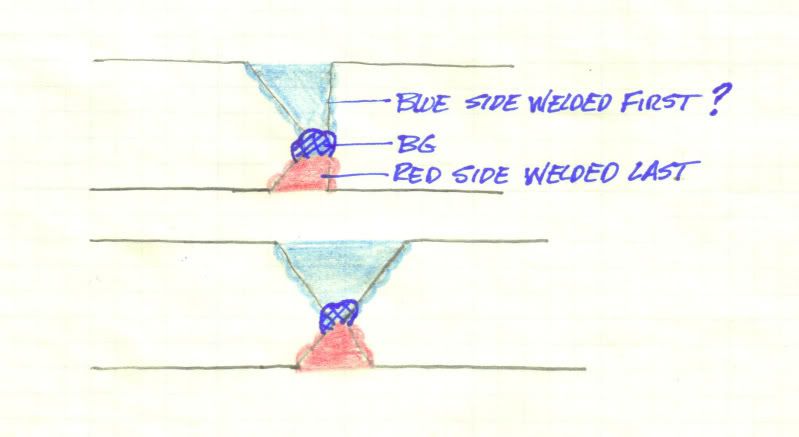

I'm with Hogan, weld metal does not become base metal, and I agree that you should be able to see some of that indication with the 70° unless the orientation is really unusual.

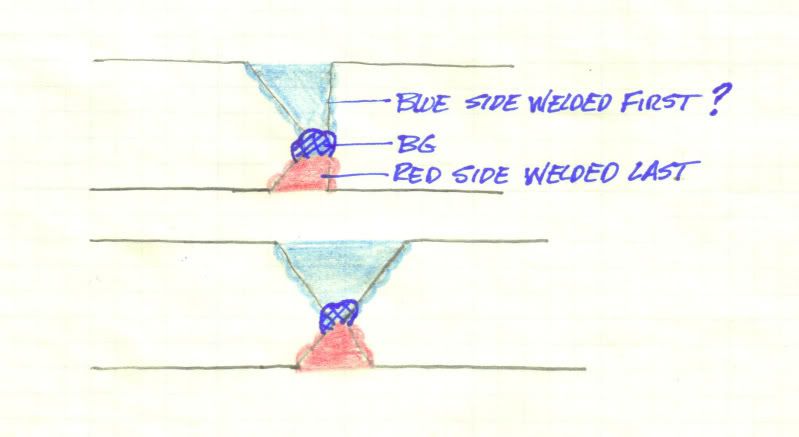

Is this joint a double-v-groove weld or a double-bevel-groove weld? (On thick joints, I often see welders "improve" the factory bevel(s) to suit their personal preference)

Are you shooting it from both directions?

Did you try hitting it with a 60°?

What characteristics lead you to conclude this is a slag line?

Did you ask if there were any repairs made during welding that would have altered the factory bevel?

~thirdeye~