Hello to all on this forum and thanks in advance for any replies.

My question is regarding the welding of 6" sch 80 pipe to a 1" base plate.The drawing shows the standard weld symbol for fillet weld but no size of weld,and the engineer is saying that a complete penetration to the inside of the pipe is required even though there is no other information on the weld symbol.He is telling me that it is standard practice that this basic symbol would mean that a full penetration weld is required.I only sporadically do small structural welding jobs but have never come across this before,so if this is the case and he is right(which I don't think so but why get into a p***ing contest) I would like to know the correct procedure for this type of weld.It will be welded using SMAW 7018.

I have been looking everywhere for my D1.1 book and it's still probably in a packing box somewhere so any clarification on this matter would be very much appreciated.

By Superflux

By Superflux  Date

Date 05-30-2009 20:57

Edited 05-30-2009 21:00

2003714,

I'd have to get into the p***ing contest on this one. Some folks live to razz others, getting freebies, etc. This is a far more involved proceedure than simply butting up plate to pipe and welding in a fillet. Perhaps in his little world, but in the "REAL WORLD" a groove fillet requires precisely that symbol and would detail joint prep angle, root opening, pentration tolerances (since it is a CJP), etc. in/on the arrow or detailed in the notes (being "typ" and repeated throughout the weldment). It is going to require a welder cerified for groove welds. Post weld NDE ???

Jump in and ream (or demean) him a new one so he looks the jerk, because he is jerking your chain!

That's my 27 cents worth.

2003714, WELCOME to the forum.

As to your question, being the weekend and away from most of my books this is going to be off my head (Oh boy, are we in trouble!!).

1) He is the Engineer, what he says is true regardless of the facts. Oops, did I say that out loud? He can call anything he wants regardless of the code and true meaning of the weld symbol used.

2) There is no way that a standard fillet weld symbol means a CJP weld is what is being called for. They can call a CJP with a fillet weld reinforcement, but just a fillet weld symbol does not do that. You could look up the examples in the welding symbols sections of several of AWS's study books, code books, A2.4 Standard for Welding Symbols book, etc. It is a completely different call out.

3) If this is for a column under compression it should not need anywhere near that much weld. I have seen huge wide flange beams with huge (especially compared to what you have) base plates and only a 5/16" fillet weld called for. Yes, there are time when there are CJP with fillet but they are special applications.

4) Why was the question posed to the Engineer? I would have just welded it like it was called. Oh, because of the lack of size call out (my bad). I believe D1.1 handles the size of fillets when welding base plates to column members under compression.

Since you asked and he defined it I believe you are stuck. If you can find the documentation to present to him and he recants then you have saved time and money.

Have a Great Day, Brent

Superflux is right, I would just want to back myself up with the books. He is the Engineer. Wrong, but the Engineer.

Gee, an engineer that doesn't know welding symbols. Boy, that's a first!

Gag, choke, .........

Best regards - Al

Boy thats a first... I hope you had hip wadders on when you said that. :-)

"The drawing shows the standard weld symbol for fillet weld but no size of weld,and the engineer is saying that a complete penetration to the inside of the pipe is required even though there is no other information on the weld symbol.He is telling me that it is standard practice that this basic symbol would mean that a full penetration weld is required."

Those kind of engineers make contractors lots and lots of money.

AWS D1.1

2.2.5 shop drawing requirements.. "shall clearly indicate by welding symbols or sketches the details of groove welded joints and the preparation of base metal"

2.2.5.3 Welding Symbols. The contract documents shall show CJP or PJP groove weld requirements. ......

The welding symbol without dimension and without CJP in the tail designates a weld that will develop the adjacent base metal strength in tension and shear"

He's way out of line. If the job did require a full pen, the detail showing a fillet is wrong, and not in accordance with the quoted verse.

All my courses include a review of welding symbols. I typically ask, "How many of you use welding symbols?"

Of course, 90% of the hands pop up attesting to their knowledge and use of welding symbols.

The class starts off with simple fillet welds and progresses to groove welds and to spot welds, stud welds, etc. It is amazing how many people; welders, inspectors, and engineers alike, can not tell the difference between a fillet weld symbol and the symbol for a bevel groove.

Best regards - Al

I guess the point I wanted make is that if the job was bid as a simple fillet weld and now he (mistakenly) assumed a grove with fillet is required for his design...this lack of communication on his part IMHO could cost you the fabricator/errector far above and beyond the bid...unless this is time and material, then hurray for you.

Ok, he is the Engineer and that gives him the right to design it any way he sees fit to place his P.E. stamp on. But! we in the trenches still have the right to not be misled and take on unnecessary work/expese because he cannot call out proper AWS welding symbols.

It is unfortunate that the weldment in question was not built per drawing, who would have known, no harm no foul and end of story.

I have successfully back charged designers for loss production and increased costs associated with incorrect welding symbols.

The contracts specified the drawings had to use AWS A2.4 welding symbols. The specific edition was listed in the project specification and that was what we hung our hat on. The symbols on the drawing were incorrect based on A2.4-XX. We charged the designer for the lost production time and the time management and engineering spent resolving the situation. On one project it amounted to a tide little sum in the range of six figures.

I've had people tell me that my firm would never see their work again if I ever tried to pull that on them. My response was that I was in the business of making a profit and if it meant losing the business of one client to keep the business profitable, so be it. I can always find another client, but it is much harder to start a new business because I went broke so as not to offend a client that couldn't or wouldn't provide an accurate drawing. Their job is to provide accurate drawings and mine was to fabricate the materials to the drawing requirements.

The fact that the engineer has a P.E. stamp does not entitle him to provide drawings with incorrect information. The contractor has every right to expect the information to be correct and accurate. Changing the weld from a fillet weld to a CJP groove weld is no small matter. The approved drawing is part of the contract documentation and has legal standing. The information presented on the drawing was not correct and would be considered a change from the original requirements and reasonable compensation is warranted. The hook of course is there must be a reference to AWS A2.4 somewhere in the contract documentation such as a reference to an AWS welding code or standard, the AISC Steel Construction Manual, a building code, etc. All bets are off if there is no paper trail back to AWS A2.4. Last, but not least, you have to be willing to sacrifice that customer for future work, i.e., they probably won't be back with new work. That in itselve may be a blessing.

Best regards - Al

Thanks everyone for your input.

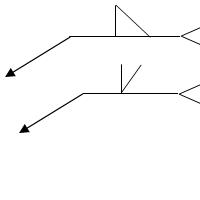

I finally got a look at the original drawings as I had been looking at a blurred scan sent via email and indeed the symbol used was for a partial groove joint( as shown in CWI555 posts second drawing).There is still no mention of CJP or size.

These are for three 9' masts that will act as tension posts for some fabric sunshades.I still think it is a little overdone but whatever gets the stamp right?They also have to be UT tested.

I've had no luck finding my D1.1 book so does anyone know the correct joint prep for this type of weld(ie bevel angle,root face, gap etc.)

Seems we all have some stories to tell regarding the engineers.It's always nice to ask the question that if they ever built an airplane would it ever leave the ground.I'm not sure they would get it though.heheThanks.

Alex

2003714,

Fabric Sunshades???? Hmmmm... PM me concerning this. I am curious.

jrw159

Alex,

I think you need to get a copy of AWS A2.4.

The drawing that Gerald (CWI 555) has posted is not a partial groove weld as you have noted.

If there are no dimensions noted on the symbol it is a CJP (AWS A2.4 Clause 6.2.2)

I don't have a copy to quote the exact statement but if you type AWS A2.4 into the search engine this subject has been raised many times before.

Now get down on bended knee and apologise to your engineer ! LOL !!!

Cheers,

Shane

I have a similar situation with a job I'm working on right now. I have an alumunum tube, 2.5" dia, with flanges welded on both ends. The drawing calls out "Weld ICW D1.2:2003". The weld symbol is a fillet all around. There is no fillet size called out. So I'm also waiting to hear back from the engineer.

If I understand correctly, weld symbols without a size called out, implies a CJP weld, but is only applicable to groove welds. Fillet welds need to have a size specification...............yes?

Jason,

There needs to be a size specification but it does not necessarily have to be in the fillet weld symbol. It can be covered in the welding notes/general notes of the drawing itself or in a separate welding detail. The detail would need to be referanced in the tail of the symbol, IMHO.

So, yes it shoud be specified, but not necessarily in the fillet weld symbol itself.

jrw159

Yes, but if in drawing notes, it does not need to be repeated on the welding symbols.

I understand, but in this particular case, there isn't anything other than the fillet all around symbol. It is a very simple and basic part, so it would be difficult to lose anything in the fine print.

However........after speaking with the customer, their response was, " just weld it". I don't understand how someone would go through the trouble of listing the code specifications, yet leave out pertinent information regarding the welds, and then come back and tell us "uhh...just weld it".

D1.2 2008

"2.2.3 weld size and length. Design drawings shall specify the effective weld length and weld size. "

"uhh...just weld it". isn't going to work. You have no idea what size and if for that matter design had designated.

I agree with Shane, Time to pucker up and apologize.

But check your contract and make sure UT is in there, or that can be a change order and recoup some of your losses.

In case it not stated in the WPS the size of the fillet weld to be used in welding the plate to support then you should look for B31.3 in case that is you reference code and you can find the typical fillet weld sizes in table 328.5.2A. Unless the specifications calls for the weld should be full penetration then your comany/you need to follow since the specs correct me if I'm wrong is more stringent that the code. You cannot follow the engineer right away just by verbal instruction you need the documents to see before you follow. Hope it will help in your query.

D1.1 was what the OP mentioned. and looking at a later post he made, he mentioned a groove weld callout without the size listed. so I'm not sure why everyone is still refering to a fillet weld. It should be a CJP weld as I see it.

$0.02

A fillet weld with the throat dimension matching the thickness of the pipe should have the same strength as the pipe if the filler metal has the same tensile strength as the base metal. This only applies to compressive loads, shear strength is a whole different ball game. That being said, the Engineer may specify a CJP with a monster fillet if they don't feel like dragging out their slide rule...

Please correct me if I am wrong.