Hello Shad, I see your point as well. Yet, in the world of shop fabrication and certain field conditions, specific types of welding/joint preparation are sometimes required to accomplish certain completed weld scenarios. In this case, CJP(complete joint penetration)required welds, this might be one way of accomplishing this. Since this is a structural application you probably can't get away with running an open-root type of joint with E60XX series electrodes. Haven't personally heard of or seen any applications of E7010 type electrodes for this sort of thing, or know if they are allowed or could be qualified without a special allowance. Multi-process approaches can be cumbersome and likely would require special qualification as well. Similarly, if GMAW were used open-root, it would likely require special testing and documentation. So the simpler approach to this is possibly the scenario I described above or some other scenarios that will not require special qualification/testing/documentation.

In this case, the work can likely be positioned and done with gas shielded FCAW(dualshield), so although it seems like an excessive amount of prep and fill it can really be accomplished rather quickly in the overall scheme of things. If I haven't explained this properly It's likely that others on the forum will correct me and do so in a proper manner. Best regards, Allan

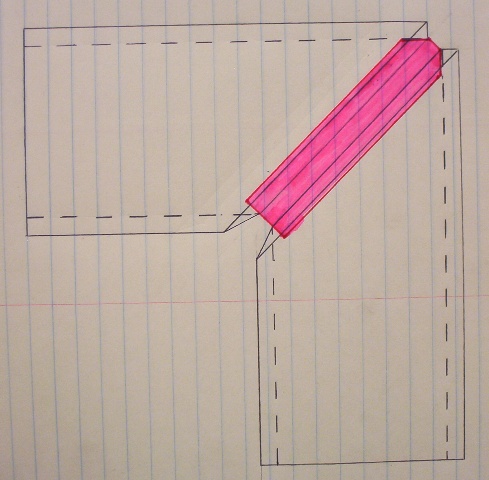

Rafterwelder, the main reason we do this is becasue the welding code calls for the backing bar to be one continous piece, including the inside raduis of the corners. The method shown above(excellent illustration by the way) is exactly how we do it.

It doesn't matter the size of the tube, but this method can be easier than trying to weld together four different pieces of bent B/B and still keeping it tight inside the raduis of the corners. Technically when you weld together the four pieces of backing, the splices of the backing need to be pull penetration welds as well, and thats a lot of work.

Hello eekpod, thanks for the further explanation, I would imagine that others will be appreciative as well. Best regards, Allan

I like your approach to the problem of CJP tubular corner joints. The plate also acts to stiffen the connection (as if diagonal stiffeners were added to the ID) to keep the "box" from distorting under load.

Open root (no backing) CJP in tubulars requires both the procedure and the welders to be qualified. That is a time consuming and expensive undertaking. The use of backing eliminates the time and cost associated with the qualification of the procedure and simplifies the qualification of the welders.

Best regards - Al

Hello Al, thank you too for including that additional bit of information. I know I always look for more ways of explaining/understanding various situations better. Best regards, Allan

Allan,

We use that same approach to CJP joints such as this one....using the plate in this fashion eliminates trying to form the "impossible" continuous backing ring and all of the impossible fitup associated with the backing ring on the inside/outside corners.