I was referring to the "What's happening to our reactors?" article.

I'll give you a few examples:

The author says: "these alloys for welding such things as jet engines and nuclear reactor pressure vessels. But it turns out that these so-self-called "SUPER" alloys aren't so super.

The "super" alloys are subject to embrittlement. Other names for "embrittlement" include Wigner's Disease, Ostwald-Ripening, Hardening, Spinodal Decomposition, Overageing (also spelled "overaging"), and "Sensitization" / Osteoporosis (cute; as in "sensitive to fracture")."

In reality, the alloys used for nuclear reactors and jet engines have nothing in common. Only jet engines use the nickel "super alloys" that are designed to be very strong as well as oxidation/creep resistant. Since water cooled reactors operate below 700F, there is no need for these "super alloys". Therefore, you can ignore all the comments above since they aren't relevant.

Another example is this, where the author says:"Also, chemicals can take hold within the microscopic fractures that start to form, and can even run down the chains and sheets, causing further corrosion and/or fatigue and/or brittle fracture etc.."

The author is talking about brittle fracture, but I think he is trying to describe stress corrosion cracking. Not to mention, "run down the chains and sheets" What the heck does that mean? Since when to low alloy steels have chains and sheets?

Or here is another one, when the author says: "The real question isn't even WHEN will this alloy or that alloy become embrittled? Today? Tomorrow? 20 years from now? Because embrittlement starts immediately, so the only question is, how embrittled are the metals? The answers are hard to find, but the indicators are absolutely terrifying"

I'll admit you have to know a little bit about nuclear to answer this one, but in reality, only the reactor vessel sees enough radiation to become embrittled. However, that is the reason that it is monitored. Each reactor vessel has specimens inserted inside the reactor, just outside the core that comes from the same material (i.e. the same heats of forging material and welding consumables). Because it is closer to the core than the reactor vessel wall, it sees more radiation that the vessel wall. So periodically, some of that material is removed and tested for toughness. So for example, after 5 years, some material could be removed and tested, and because it has seen more radiation, it could demonstrate what the reactor pressure vessel toughness is after 10 years. So indeed, the reactor vessel toughness levels are known well before hand. The vessel is designed with excess toughness before it goes into service so that the toughness level will never fall below the minimum requirements. So the answer to the authors question is: they know exactly how embrittled the metals are.

Here is an easy one, where the author says: "It is welded to the outer Pressure Vessel by INCO-182, at least if done in the 1950's-1980's, if not even 1990's to today!? (maybe INCO 82 which may be the same thing (European name))."

Inco 182 is the SMAW version of the same metal as Inco 82, which is solid wire for GTAW/GMAW/SAW/etc. It has nothing to do with Europe. If the author doesn't know if they are the same thing or not, why include it?

Basically, the whole article is just the author is trying to scare people with off the wall, unsubstantiated guesses.

As for your other questions:

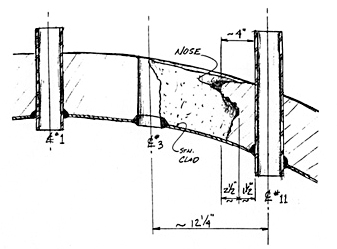

Why would Toshiba conduct the laser overlay study? Well, I'll admit that nuclear reactors aren't perfect. Unlike the fictional article's premise that nuclear reactors are not inspected, they are inspected on a regular basis. When flaws are found, this is one way to fix them. At one point, it was thought that alloy 600 was immune to stress corrosion cracking. However, it was not. It has known problems with known solutions. The laser cladding is one type of solution.

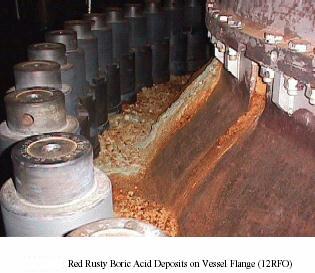

As for the other article on core thermocouples, would you not want reactor vendors to study ways to make them safer? It is their duty to make them as safe as possible, you can't criticize them for studying it. The Davis-Besse issue is another matter. The main problem was a worker fraud from what I understand. The guy went to jail. If that had not happened, the problem could have been addressed long before the reactor head had become corroded to that extent. However, it can also be used as an example of how much design margin that reactors have.

If you want to read something worthwhile about nuclear power, try Terrestrial Energy by William Tucker. It isn't very expensive.

http://www.terrestrialenergy.org/