waccobird,

Underrun is mentioned in Table 6.1(6) Undersized Welds, and is in regard to acceptable/unacceptable fillet weld sizes within a given fillet weld length…. “underrun shall be prohibited at the ends of web-to-flange welds on girders for a length equal to twice the width of the flange”.

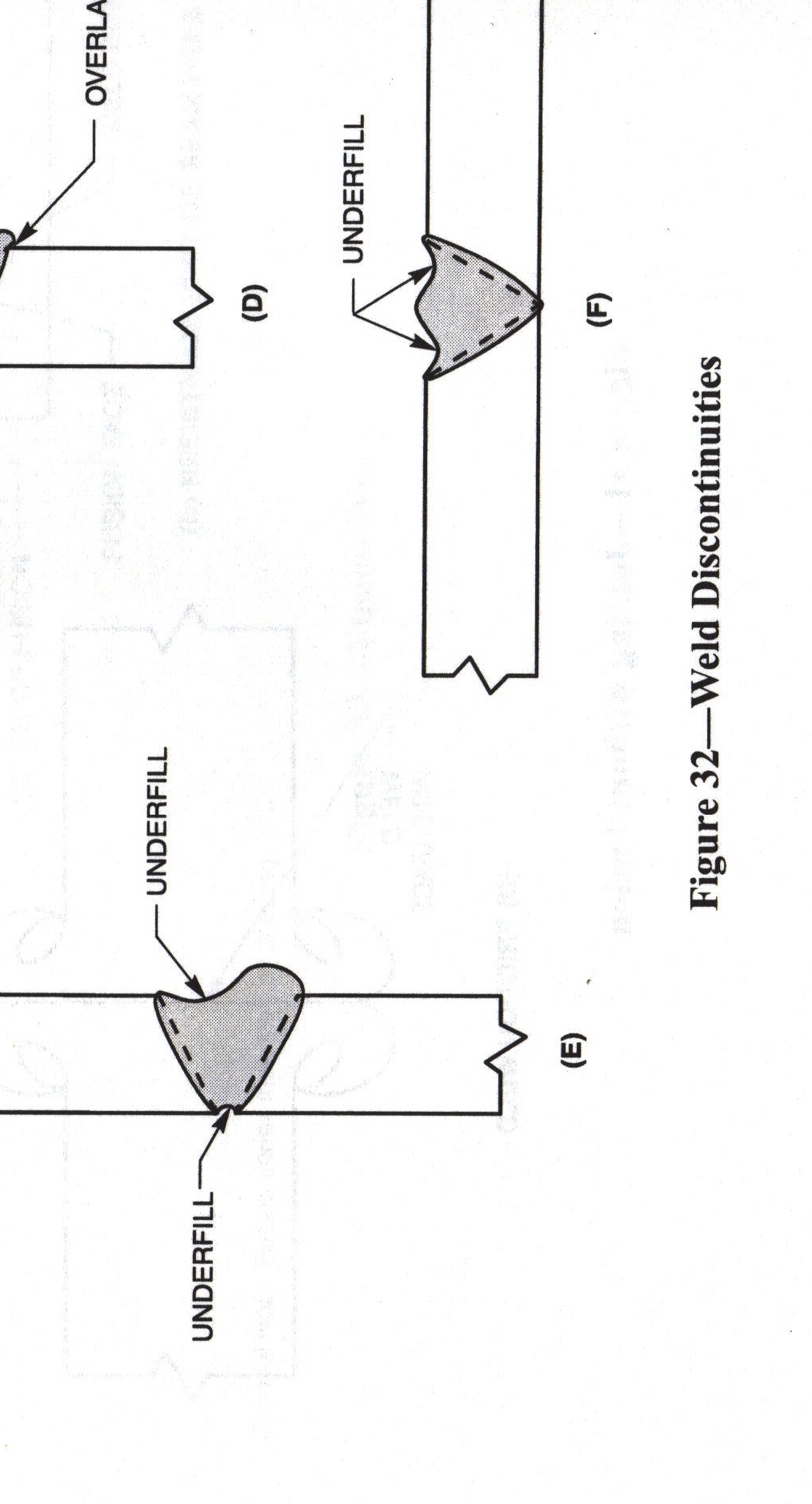

Underfill has been defined in a previous post in this thread and is definitely an unacceptable weld profile in accordance with Figure 5.4, but an underfilled groove weld is not necessarily unacceptable. For example, the required design thickness for the groove weld joint may calculated to be a 0.55" thick plate. The engineer typically rounds up to the next standard thickness, probably a 5/8" thick plate. If the weld is underfilled, the actual thickness of material required could be used as an acceptance basis, rather than D1.1 criteria. However, as we all know, only the engineer can make this determination.