By 803056

By 803056  Date

Date 09-24-2009 02:39

Edited 09-26-2009 05:27

Many engineers will not approve the splicing of members intended to be one piece members. That would rule out cutting the member, adding a foot as suggested, and then trimming to the proper length. Other engineers would look at the proposed "fix" as reasonable if the member is a secondary member subjected to static loads.

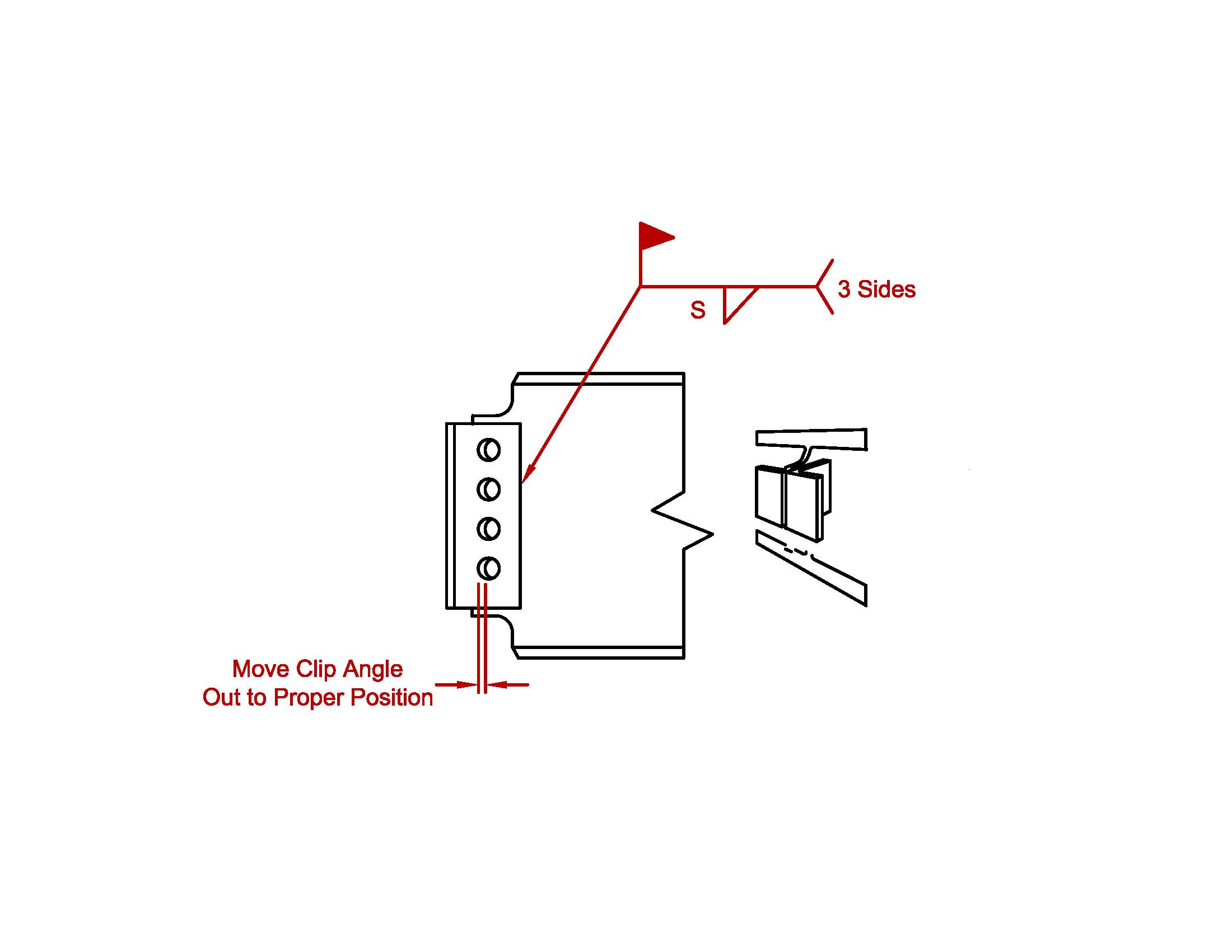

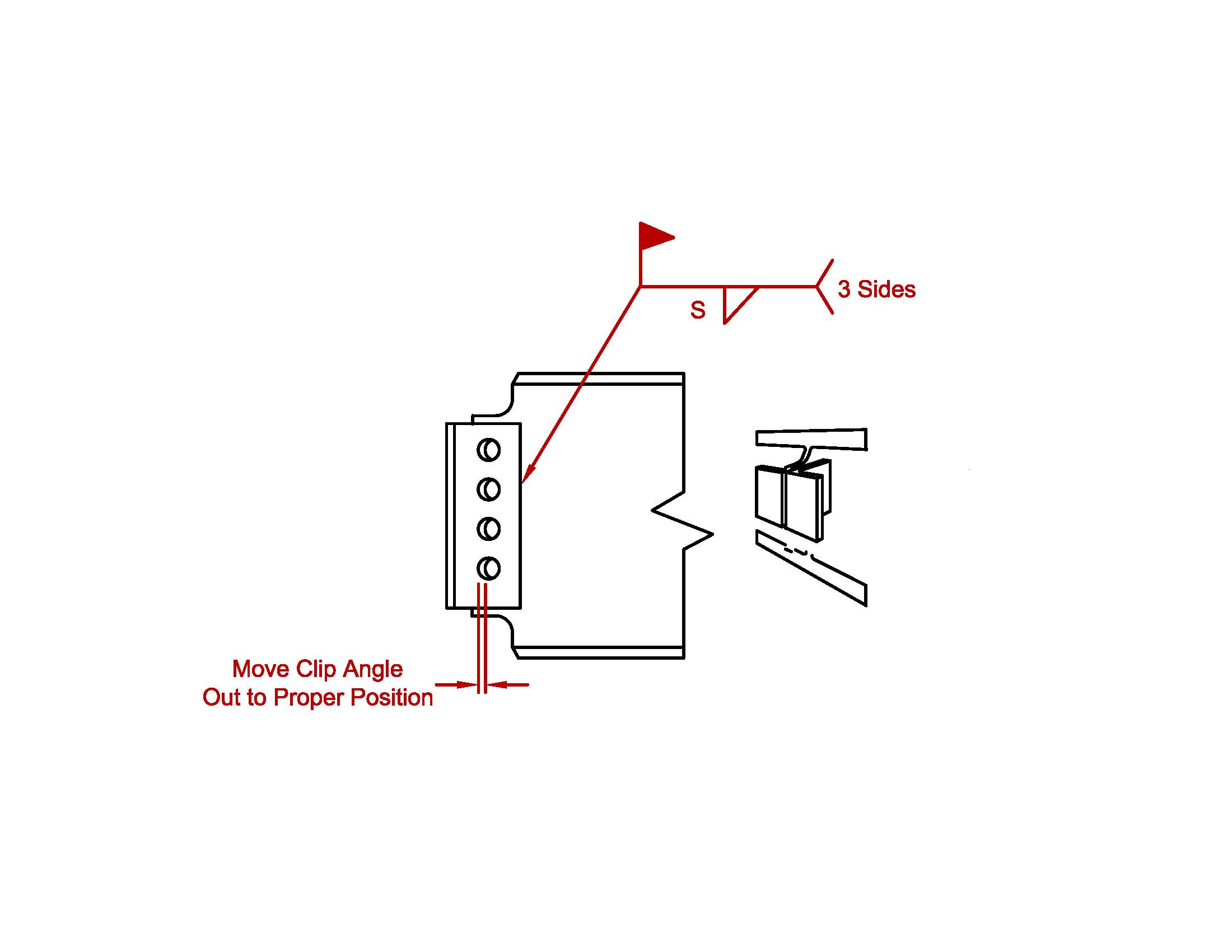

Another possible fix is to weld the connection in the field, i.e., detail the connection with two fit-up bolts and weld the clip angle to the web in the field. If the connection calls for a knife connection (bolts in double shear), weld both clip angles to the beam web (in the field). The problem of edge distance is moot and the welding requirements are reduced to simple fillet welds. The connection is still a "simple frame connection". The two erection bolts would allow the erector to plumb the structure before completing the field welds.

It might be difficult to obtain the engineer's approval for any shop repair (to the beam) if the beam is a primary member subject to cyclic loads. The field welded fillet welds would not compromise the connection and would not require CJP groove welds or ultrasonic examination.

The Engineer, not the fabricator, would have the last word with regards to accepting a repair or demanding a replacement beam.

Sorry some of the lines in the sketch didn't reproduce. Don't know why. This was a field fix I came up with for a client. I wasn't the TPI, in this case the erector asked me for a proposal so he could correct the problem in the field. I gave him this sketch which he presented to the Engineer. The proposal was accepted and the fix completed in the field with minimal interruption to erection.

Best regards - Al