Is it possible to repair a weld on 8620 hardened and carburized to RC 55-60 .062”deep? The bigger question is how I prevent it from happening in the first place. Here is some information on component and WPS; 8620 cold finished round is annealed and is being joined to A36 plate, pre heat shaft 250°F, GMAW, ER70S6, 95/5, 40-45CFH, 26V, .045 Wire, 575IPM, Weave, Travel 9-10IPM. I am inspecting this weldment before it is sent to be hardened usually after 48 hours from the time of welding. The weld is being machined flush no cracks appear present before it is hardened and the weld area is checked with PT. When the component returns from the hardener some of the weldments have cracks usually in the weld interface on the A36 side of the weld, I was told it has always been like that.

Any input would be appreciated

Thanks,

Rey

Hey Rey

Just for starters a few thoughts:

Weaving Spray GMAW is never a good idea. Even if no lack of fusion is evident, you are putting way more heat into your base metal than if you ran a series of reasonably sized stringers.

95/5 Vs 98/2 Reducing oxides and still getting reasonably lower voltage spray transfer.

Or even MCAW or FCAW might produce better productivity and mechanicals with stringers.

.045 solid wire @ 575 ipm (someplace close to 400a) is a little above the maximum any manufacturer even recommends for that type of solid wire. Add to that the heat input from a weave type deposition and I think process control may be an issue to be addressed.

Taking the extra time to run stringers or use a larger diameter FCAW or MCAW electrode might be recovered in reduced rework.

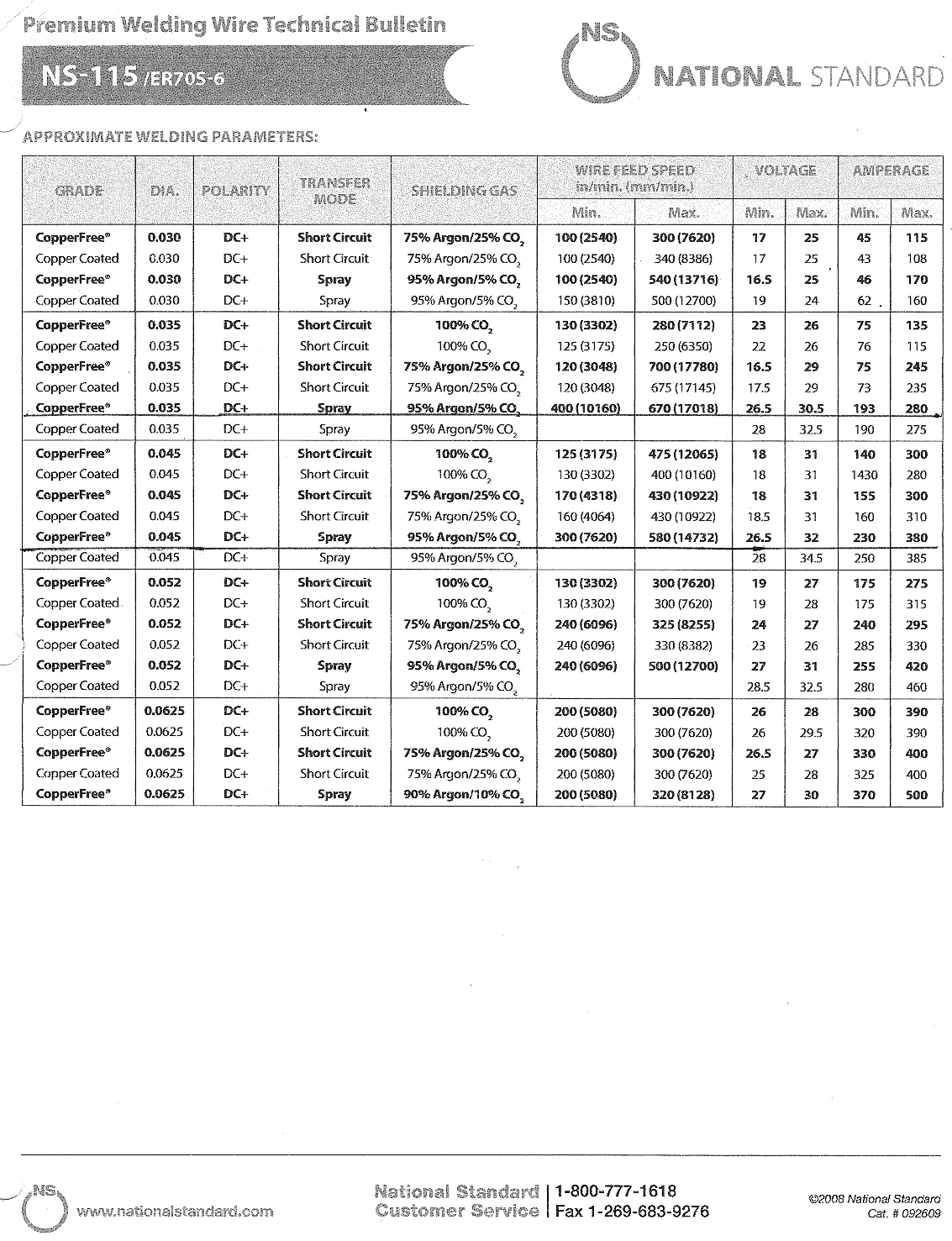

I think there pushing the size of the weld also in AWS D14.3:2005 7.5.8 Prequalified Procedure for Gas Metal Arc Welding GMAW (4): The thickness of weld layers, except root shall not exceed 1/4”. The welding supervisor gave me this sheet for the wire (See Attached)

Rey

Do these cracks go deeper than the 1/16" deep case hardened layer? My guess is that they are forming at the end of the quench cycle after the martinsite has formed. Untempered martinsite has little elongagation.

If the cracks are at least initally located only in the hardened area, do they propagate into the soft material when the part is in use, or do they remain stable?

Dave

Thanks for the response, they do not remain stable they do propagate to the point of part failure if the part is put in to use and I have no way of ascertaining the initial depth.

Rey

I will go out on the limb a bit, and guess that the parts are water quenched and not tempered. If You can't resolve this issue with a filler metal or weld process change, You might try tempering at 400-500F immediatly after quenching, specificly before the part cools below 150F.

Thanks Dave

I will have to look in to that I do not know but it does not specify tempering so, you might be on to something.

Rey

Another thought, if the welded area doesn't need to be case hardened for wear resistance, perhaps that area could be masked from the carburization process.

If You go with the tempering, temper at as high a temperature that will still give the desired RC hardness.

A slower quench medium may help also, but with the materials You are working with You may need to stay with a fast one to achieve hardness.

Mr. McLead

In my opinion, E70S6 is the wrong alloy for the 8620 base metal.

Joe

I had some concerns of welding the A36 to the 8620 and then heat-treating, I did not know it the two steels acted the same in expansion and contraction.

What weld metal do you think would be more appropriate?

Rey

Try 70 S 3 as it is closer to A 36 than 70 S 6

I would not recommend welding on it in the hardened condition. The temperatures associated with welding will anneal the base metal in the HAZ and lose the properties you are trying to achieve. There may also be further cracking in the HAZ.

With the J-weld prep that is being used, it looks like lack of fusion is a possibility, especially if this weld is performed in a single pass. Can you use a U-groove prep instead? The higher manganese content of the ER70S-6 does tend to push the weld strength up, so perhaps ER70S-3 would give a little more ductility. To really understand why they are cracking, you will need to cut one of the parts through the cross-section of the weld and examine for complete fusion or microstructural problems.