Bill,

First off, in the original thread the reason why this discussion led to an agrument and then eventually into a total mess was simply because the OP wrote that the base/parent metal was a 4" dia. schedule 120 S 31803 22% Cr, 2205 Duplex grade of SS, and NOT a 25% Super Duplex which is IMHO, a big difference between these 2 Base/Parent metals, don't you agree??? And by just looking @ the test temp for the corrosion test alone, would it be prudent to

ASSUME that the Base/Parent metal automatically be a super duplex grade even though the OP clearly wrote that the pipe was a 22% Cr, S31803 2205 Duplex grade of SS??? I didn't think so which is the reason why we got inot the never-ending dispute over this topic!!! All anyone has to do -is to simply follow the original thread chronologically, and anyone can see that the OP (Original Poster wrote that the pipe was 22% (s-31803) 2205 Duplex grade of SS and NOT "Super Duplex"... The only reference from the OP regarding a 255 Cr Super Duplex metal at all was when he was referring to the grade of filler wire used for the root pass which was deposited via GTAW... All of the subsequent passes were deposited with a 2209 (22% Cr) FCAW filler ,and I truly believe that is where all the confusion started - PERIOD!!!

I never disagreed with your conclusion, and in the original thread I acknowledged it also... Nor did I elude your question regarding the test temperature being too high for that specific grade of duplex either, and I answered your question with an emphatic no more than once!!! Yet you still have this notion that I' disagree with ytour conclusion and I do not understand why???

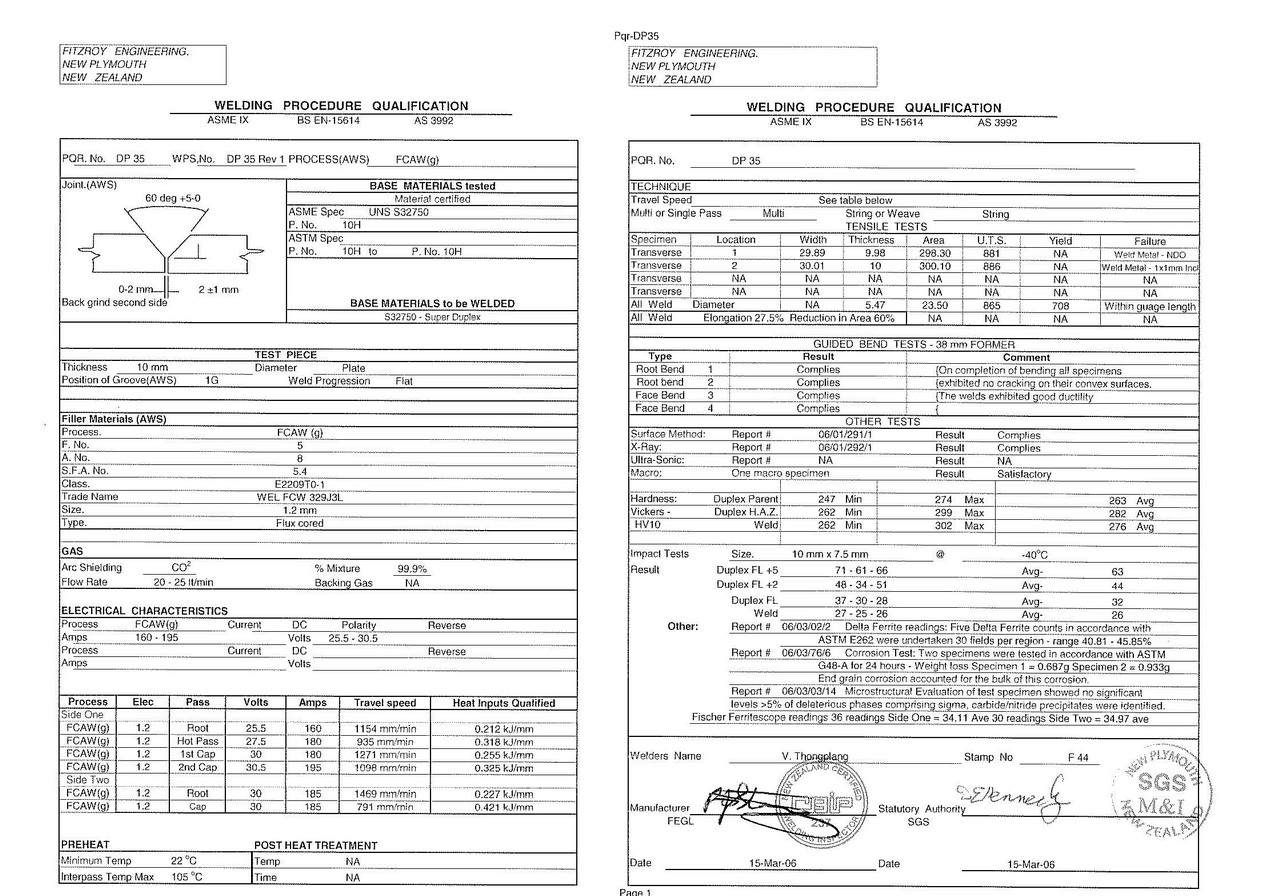

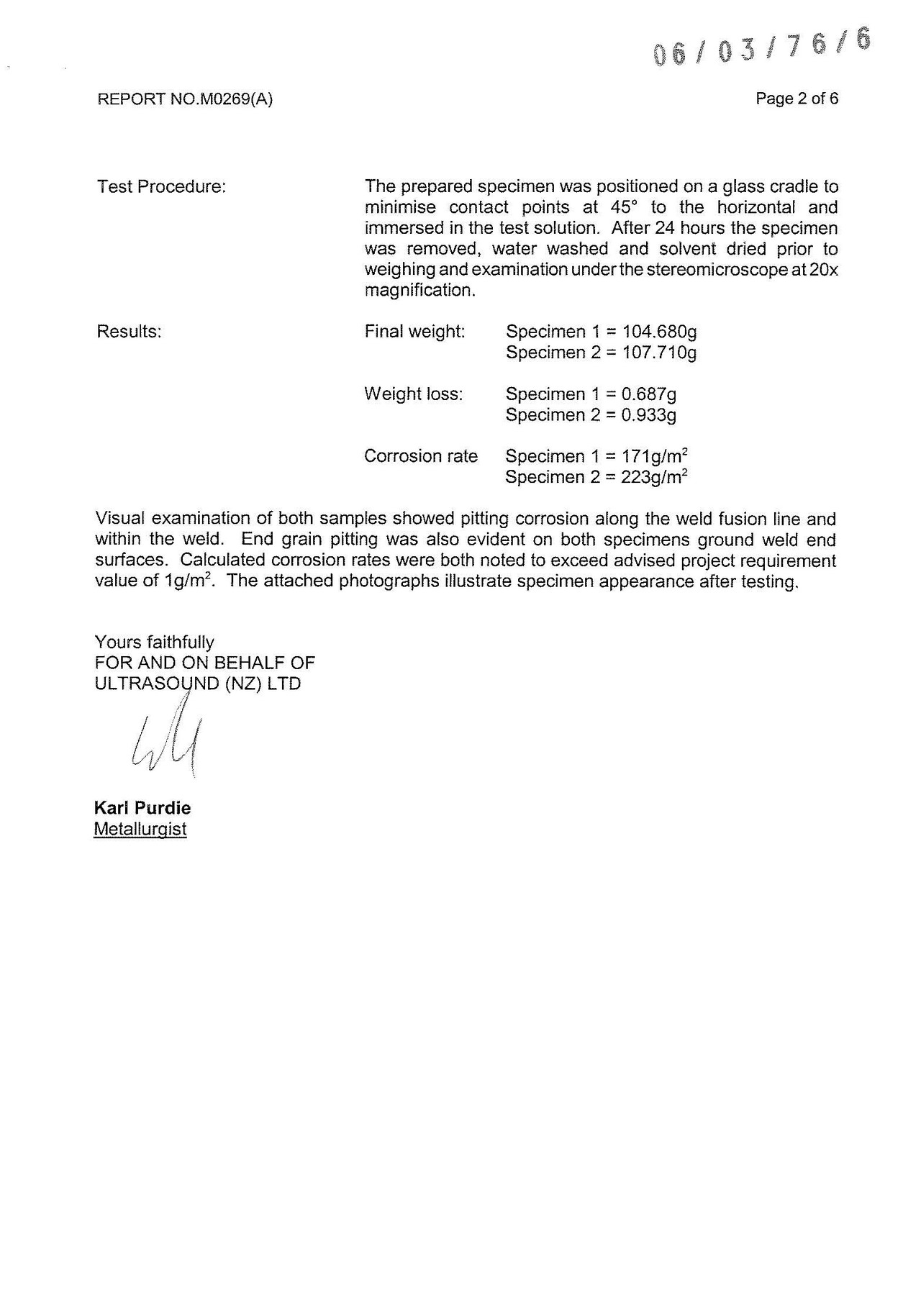

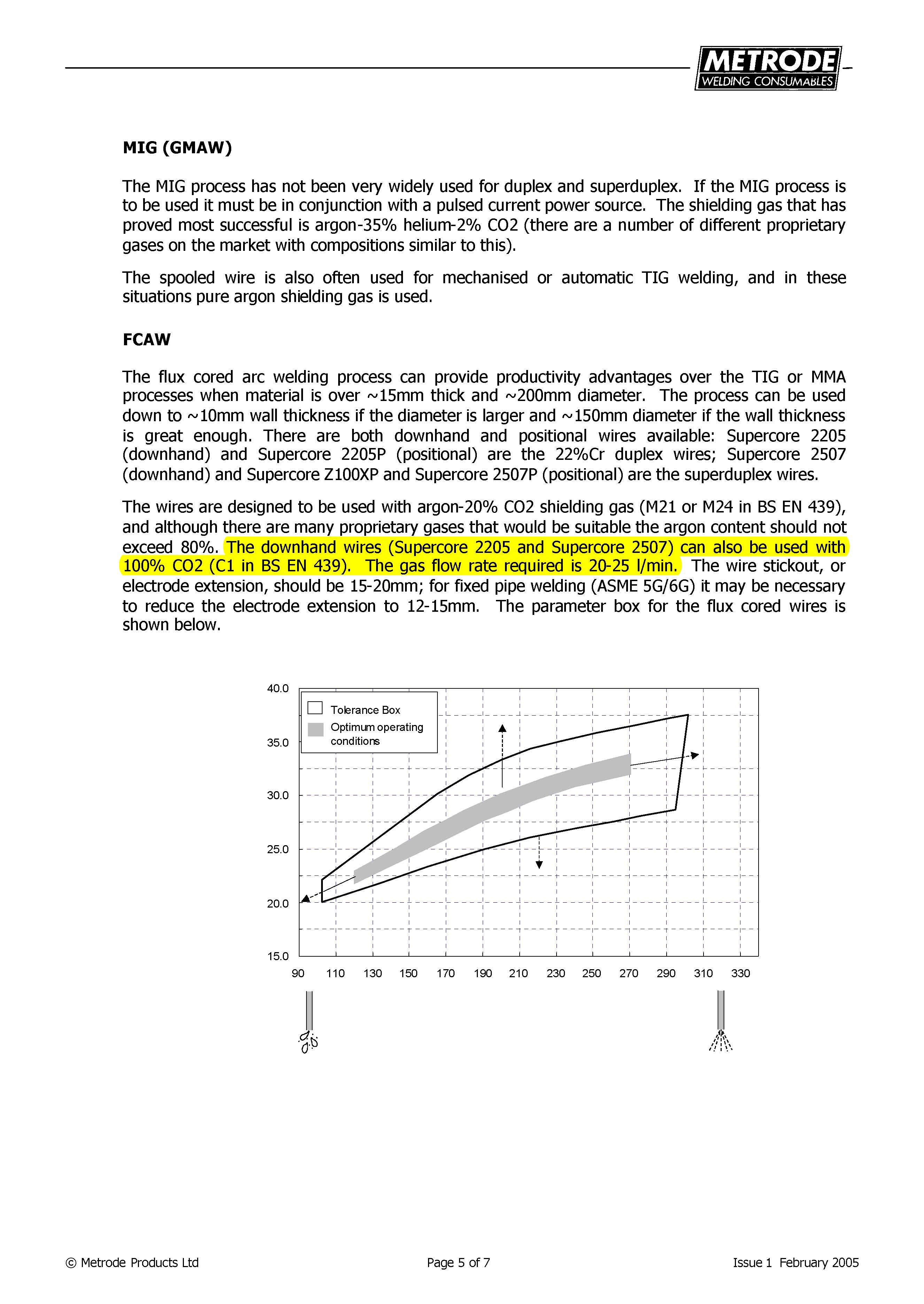

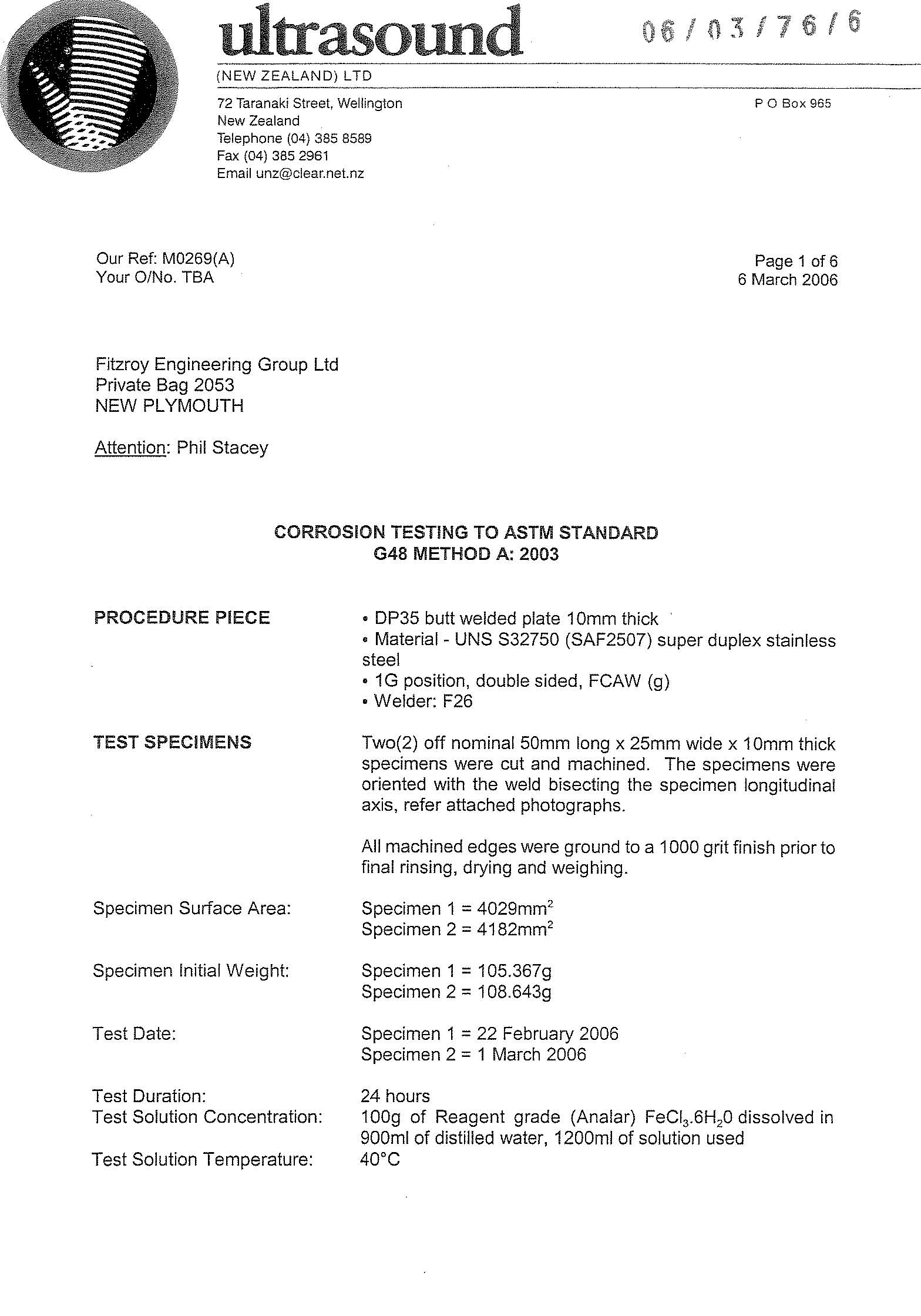

This WPS and supplementary data doesn't tell anyone what was the G48 test temps, and I too wasn't aware that you could use CO2 for shielding gas when FCA welding of Super Duplex grade SS??? I haven't checked, but does Metrode recommend that also???

Finally, when I said: "As to this being only "recommendations and not cast in stone." It doe not mean to disregard the Manufacturers recommendations at all! It means that the recommendations are just that - Nothing less as well as Nothing more ,so I would appreciate it that you would NOT add words that clearly I did not write at all, because when you do so, you only start another round of confusion and mis-communication... If you need clarification as to what I am writing, all you have to do is ask, and I would be more than happy to follow up.

In summary, I would like to propose that this topic be concluded right here and right now, so as to bring in the New Year with the proverbial slate wiped off clean, and hopefully staying that way through a renewed mutual effort in promoting once again,

MUTUAL RESPECT IN THIS FORUM. ;)Sincerely,

Henry