Hi Joe,

First and foremost especially with Titanium,

"Cleanliness is Godliness!!!" So make sure you remove even the slightest oxide layer just prior to actual welding by using a dedicated Stainless steel wire brush just for Titanium... And this is to be done regardless of whether or not prior cleaning was performed beforehand because it doesn't take long for a thin film of Ti oxide to form over the weld surface - CAPECHE??? This MUST be done in order to ensure that there will be no Ti Oxide contamination within the weld area...

Then you need to make sure that when welding Titanium, you have a higher than normal purity percentage in both the shielding as well as the backing gas, and the trailing shield gas also... Typical specifications suggest that shielding gas be at least 99.995-percent pure with no more than 20 parts-per-million (ppm) of oxygen and a dew point greater than -50- to -76-degrees Fahrenheit. Other applications require a 99.999-percent pure flow of argon.

Outfitting your welding torch with a trailing shield is critical—otherwise the risk of oxygen contamination rises, and with it the potential for cracking. Some people fabricate their own trailing shield but there are also fixtures available for purchase. Trailing shields conform to the shape of the tube and follow the TIG welding torch around the pipe. The shields provide an extra protection of argon over the weld after the torch and its argon flow have passed. Setting the torch and trailing shield gas flow at 20-25 cubic-feet/hour (cfh) provides the best coverage. Now if one cannot use a trailing shield, then a really large bore gas nozzle cup is definitely recommended along with the use of a gas lens collet body that has a large enough diameter for the oversized gas cup one is going to use for Ti.

Back purging is also required when welding titanium tubing. This process eliminates the oxygen contained within the pipe by using any variety of a back purge dam: water soluble purges, non-rubber gaskets, specialty tape or inflatable bladders. Argon flows into the dammed area to replace the oxygen contained within the tubing. Allow the argon to flow long enough to replace the oxygen ten times over to ensure the purest welding environment. Always use a clean, nonporous plastic hose to transport the shielding gas to the torch, trailing shield and back purge. Rubber absorbs oxygen that could contaminate the weld.

Does the WPS have a post flow amount written in it???? Because if your post flow is less than 20 seconds, then this could be the cause of getting so much color in the weld... What you do not want to do is to remove the gas shielding prematurely - before the temperature of the weld cools down below the 800-degree Fahrenheit threshold. This is the point at which oxygen can no longer react with the titanium. Some codes may require that post-flow remain until the temperature drops below 500-degrees Fahrenheit, so always follow procedure, and if the procedure isn't sufficient, then revise it, so it does give the desired results-PERIOD!!!

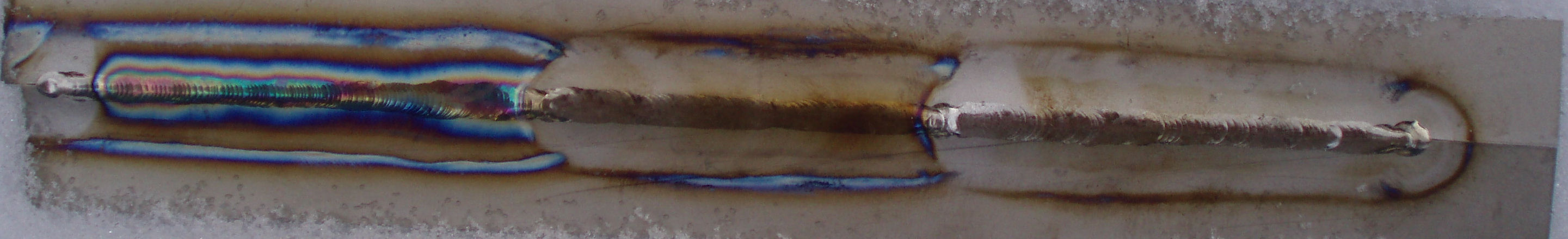

Titanium offers the benefit of showing its true colors once the weld is finished. The final color of the weld joint indicates how well the shielding gas protected the weld from contaminants and how thick the oxide layer is. ;)

Respectfully,

Henry