You're right about Titanium being relatively easy to weld as far as weldability is concerned except for one, or two, or even more than three small, yet very important factors that is a must to be considered when welding Ti outside of an enclosed inert atmosphere in order to achieve consistent, metallurgicly sound, successfully welded joints of any configuration...

If the bag did successfully shielded the Ti from being contaminated by the atmosphere, then I wouldn't say that the person lack experience because they did it that way as long as the person who used this method carefully considered all of the inherently important factors that must be incorporated with the use of such a temporary enclosure such as calculating with an added factor of assurance that the volume of atmosphere inside the temporary enclosure was removed from the enclosure at least 10 times it's volume...

And an ultra high purity grade of argon (UHP grade Helium is also normally used on thicker Ti material due to increased penetration.) was used along with a minimum -50 f dew point, and finally the person welding took extra care in ensuring that the metal was properly cleaned of any potential contaminants, and wore gloves that would not leave any type of residual contamination on either the filler metal or the base metal itself along with cleaning the filler metal just prior to the start of actual welding also, then I don't see anything wrong with advocating that method at all IMHO...

In fact, in the field where there are not as many controls with respect to the environment, we also set up temporary enclosures along with incorporating the same methods used in our main fabrication facility also only because of the type of stringent NDT methods used that was also a customer requirement beyond what the code we were working to required as well. ;)

Titanium being welded out of a glove-box type configuration whereby the joint is enclosed in a temporary inert atmospheric containment vessel, is engulfed completely by Argon...

If one is to weld without the use of such containment, it is required that the joint have at least two of three types of shielding surrounding the joint during welding...

Titanium, whether it be a CP (Commercially Pure) grade, or any of the Ti weldable alloys, are both reactive to certain elements found in the atmosphere ( Nitrogen, Oxygen, Carbon Dioxide, etc. ) mainly because of the element Titanium itself along with some of the other rare earth elements (Ti is no longer considered nor should it have been considered an "Exotic" metal since it is the ninth most abundant element found on earth and the fourth amongst metals, much like Aluminum once was thought as an "exotic" metal also.) which may also be used as alloying elements in certain grades of Ti...

Hydrogen is another element which will cause contamination in Ti welds which is why the metal must be not only as clean as possible from any thin layer of hydrocarbons or moisture, but also the handling of the Titanium must not be done with bare hands and appropriate gloves which will not leave any type of hydrocarbon residue must be used...

And when one is one is welding a binary phase type of Ti, or a Ti alloy such as an Alpha-Beta type, prevention of the metal from reacting to the atmosphere which is made up of mostly nitrogen and at the very least 18% oxygen along with smaller percentages of other gases and water in the form known to most of us a relative humidity, is the most important factor to consider when welding because most of, if not all of the elements found in the atmosphere cause the metal, whether it be commercially pure or a Ti alloy - to react badly to them and there's no getting around that... This is why it is strongly recommended that Titanium be welded using a very high purity grade of argon as well as at least a -50 F dew point also in order to prevent any moisture from being introduced into the inert shielded weld zone and possibly contaminating the welded joint.

Now this doesn't mean that one must weld the Ti in a totally enclosed inert atmosphere in order to achieve metallurgicly sound, successful welds where there is limited to no reactivity to the atmosphere surrounding the joint being welded. However, to say that one can achieve metallurgicly sound successful welds without the use of at least a backing shield on the joint engulfing the backside of the joint prior, during and after welding as well as extending the time of gas post-flow being used for the GTAW torch and not having to hold the torch in place once stopping to ensure coverage of the solidifying weld pool for at least as long as the extended shielding gas post-flow rate is set to and finally, not being concerned with welding the Ti at the lowest heat input possible is to almost a guarantee that most of the joint will be contaminated, the weld will indeed be brittle even though it may "look good" and is relatively "easy to weld," the weld will eventually fail in short order if it hasn't already failed once the weld has been completed without the aid of some sort of backing gas shielding for the backside of the joint...

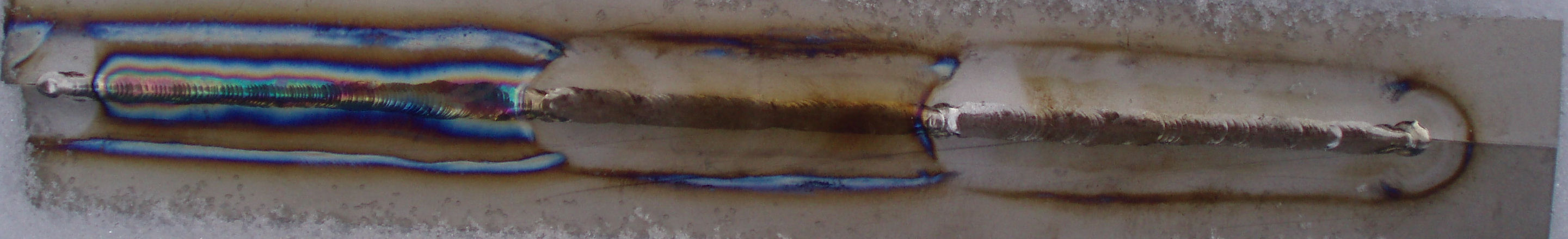

So one of the two important factors is the fact that the backside of the joint must be shielded prior to, during and after the welding is completed at least until the base metal along with the welded area has cooled down to certain safe temperature which can be different according to (The USN uses below 600 F, and Titanium Fabrication Corp used below 450 F even though Timet, which is one of the world's foremost producer and experts in Titanium recommends below 800 F which probably the maximum safe temperature where the metal will not react to the atmosphere surrounding it.) various groups who are welding Titanium... Then there is the inescapable fact that if the solidified weld metal itself that is now behind the weld pool as the welder advances along the joint being welded, is not properly shielded from the atmosphere, and is exposed to the atmosphere before it has cooled down to a non-reactive temperature, then the weld will indeed become contaminated and as such, the Ti will have reacted!!! Hence the term "Reactive metal." and one can easily notice it by the color of the weld and it's adjacent area...

So, the welding of Titanium without a trailing shield is very limited to relatively small sized joints where the risk of contaminating the solidifying weld behind the torch is very low indeed! ;) Still, I prefer to use one of those "Monster" type cups along with the larger than normal sized gas lens diffuser/collet bodies for welds that are short in length and can be completely engulfed by the gas shielding plume once I have completed the weld and extinguished the arc Now some of the trailing shields shown in pictures may seem to look bulky, but there are designs that are much more streamlined and more operator friendly to use with a GTA welding torch

If the shielding gas post-flow rate is set at a normal setting when one is welding Aluminum, carbon, or stainless steels, the Ti will react badly at the weld crater once the welding has stopped, and if one uses a dabbing technique when manually feeding the filler metal into the molten weld pool and inadvertently pulls the filler end that was just shielded out of the gas plume even ever so slightly, one will be introducing contaminated Ti filler metal into the weld pool and therefore contaminating the joint...

Here is another interesting foot note:

Titanium Weld Color:A Potential Indicator of Weld QualityA common question when welding titanium is, How important is the discoloration of the weld surface?

Weld color can be an indicator of an unacceptable weld, but everyone involved in titanium fabrication—designers, engineers, welders, fabricators, and inspectors—should keep in mind that discoloration should be used as part of the decision-making process and not the sole factor in weld acceptance.

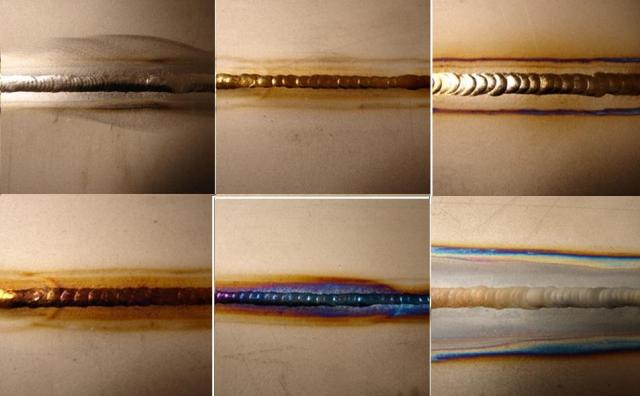

The chart below shows a range of colors that may develop when titanium is exposed to atmospheric conditions at elevated temperatures. The color change is an indication of the thickness of the surface oxide (rutile) that develops and, thus, an indicator of the degree of weld contamination that may have occurred. With minimal or no oxidization, the surface color will be silver or light straw, while in severe cases of oxidation, loose, flaky white or gray deposits form.

If a contract specifically requires evaluation of weld color, the AWS D1.9 Structural Welding Code— Titanium can be a useful reference. The code specifies the inspection requirements, qualifications, and responsibilities for individuals evaluating welds and provides detailed color acceptance criteria in the form of Table 5.3.

When discoloration is found in a weld, the welding team should examine the welding equipment, filler wire, and work environment to understand the cause. For example, a contaminated tungsten welding electrode is evidence that the quality of the primary shield gas has been compromised in the welding torch lines, whereas contamination at the end of the filler wire could be an example of a poor wire manipulation technique.

Ineffective shielding can lead to discoloration of the weld as indicated in the chart below. Possible causes of ineffective shielding are the location of the welding area, such as near a door or vent where the air current flowing across the weld can cause the inert gas shield to fail to some degree. It is imperative to perform welding in an area free from drafts to prevent hot weld metal from being exposed to atmospheric oxygen and nitrogen if bright, shiny silver welds with minimal contamination are required.

Unlike GTAW, GMAW presents new challenges to the issue of weld discoloration. GMAW produces a titanium vapor in the weld arc that deposits onto the cooler weld surface as finely divided titanium particles. Because of the reactive nature of titanium, these particles will combust spontaneously upon exposure to atmospheric oxygen once outside the protective weld gas shield. The nature of the resulting black deposit on the weld makes it difficult for inspectors to use color guidance charts as a reference for visual inspection of weld color. It is therefore very important that every manufacturer establish and approve welding inspection procedures applicable to the specific welding processes adopted.

I could go on and on but, I'll end this post by adding these links which I consider very good ones regarding the proper welding of Titanium without an enclosed atomspheric vessel and hopefully these links will be educational to whomever wanting to learn more about welding Titanium and its alloys! ;)

http://www.millerwelds.com/resources/articles/TIG-gtaw-titanium-weldinghttp://www.timet.com/pdfs/ti-handbook.pdfhttp://www.weldingtipsandtricks.com/welding-titanium.htmlhttp://www.kobelco.co.jp/english/titan/files/details.pdfhttp://www.aws.org/wj/june02/feature1.htmlLarry will like this one about a hybrid plasma/Gas metal arc experimental welding process for use on Titanium called "Super MIG!":

http://www.spaceformtech.com/pdfs/SuperMigTitaniumWelding.pdfhttp://www.wtia.com.au/pdf/TGN-MS-02%20Titanium.pdfhttp://www.weldreality.com/Titanium%20Data.htmhttp://www.struers.com/resources/elements/12/38860/e-Structure%203_EN.pdfThere are 2 pictures attached which show good examples of what is a good sound weld and a bad one should look like... On of them was posted by my esteemed colleague Al in a previous post and I wanted to include it along with the color chart in the second picture so that one could use Al's picture to distinguish the acceptable weld from an unacceptable one using side by side comparison with the chart, so take a look at both pictures. ;)

TITANIUM WELD COLOR TITANIUM WELD QUALITY

BRIGHT SILVER - ACCEPT BUT REMOVE DISCORATION IF MULTI-PASS WELDS

SILVER - ACCEPT BUT REMOVE DISCORATION IF MULTI-PASS WELDS

LIGHT STRAW - ACCEPT BUT REMOVE DISCORATION IF MULTI-PASS WELDS

DARK STRAW - ACCEPT BUT REMOVE DISCORATION IF MULTI-PASS WELDS

BRONZE - ACCEPT BUT REMOVE DISCORATION IF MULTI-PASS WELDS

BROWN - ACCEPT BUT REMOVE DISCORATION IF MULTI-PASS WELDS

VIOLET - UNNACEPTABLE. REMOVE IF MULTI-PASS WELDS

DARK BLUE - UNNACEPTABLE. REMOVE IF MULTI-PASS WELDS

LIGHT BLUE - UNNACEPTABLE. REMOVE IF MULTI-PASS WELDS

GREEN - UNNACEPTABLE. REMOVE IF MULTI-PASS WELDS

GREY - UNNACEPTABLE. REMOVE IF MULTI-PASS WELDS

WHITE - UNNACEPTABLE. REMOVE IF MULTIPASS WELDSA positive feature of welding titanium is the color of the weld beads which will give a good indication of the effectiveness of the inert gases on protection of the parts from the atmospheric gases... The aim when welding titanium should always be to produce a bright silver weld. Any discoloration outside the silver weld indicates that some reaction with oxygen has occurred either during the actual welding or during the cool down period.

Any weld discoloration should be cause for stopping the welding operation and correcting the welding problem. Light straw-colored weld discoloration can be removed by wire brushing with a clean stainless steel brush, and the welding can be continued. Dark blue oxide or white powdery oxide on the weld is an indication of a seriously deficient purge. When the discoloration takes place, stop welding immediately and review the causes of the oxide reaction.

Also, if one uses the search function and types in Titanium, you'll find plenty of posts with some interesting links to some really good articles on Titanium welding as well as metallurgy in this forum, so enjoy the reading!!! :) :) :)

Respectfully,

Henry