Not logged inAmerican Welding Society Forum

Dear Member,

In AWS D1.5 (I use 2008 Edt.) on page 140 Para 6.15.1 describes UT equipment. '' The UT instrument shall be the pulse echo type and suitable for use transducers oscillating at frequencies between 1 MHz and 6 MHz. The display shall be an 'A' scan rectified video trace'' The client ask for examination record? Is it possible to get A Scan record . I dont mean print out of examination it is almost one of the specification for all UT flaw detector in market. I am asking is there any convantional UT equipment cant get the all scan/exam by using a software interface?

If I use TD Handy or Omniscan PA equipment with A scan it is allowed regarding to AWS D1.5 and Can I get the video record.

Thanks

Yasin

In my opinion "video trace" means a standard rectified A-scan display. I also believe that only encoded examinations can be recorded - whether this would ever apply to an A-scan seems irrelevant when encoded TOFD and PA is available as you rightly point out.

Regards

Nigel

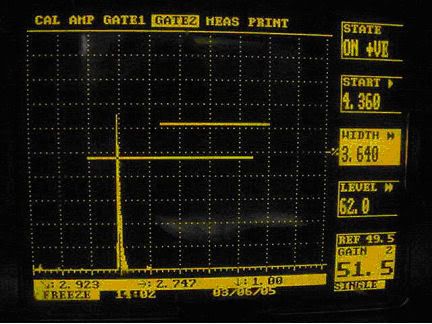

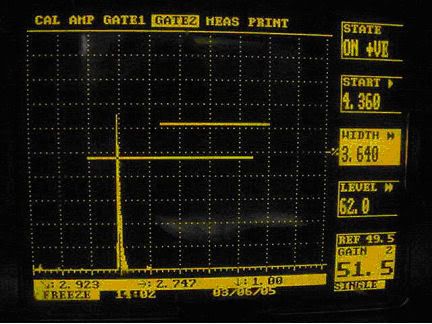

The report you submit is the examination record according to D1.5. If the client wants to see an actual rejectable indication signal, why not freeze the display and just take a digital picture of it. I've done that in the past when requested. NDEGUY is right about the encoder interface. Why get this complicated for working with bridge code? Even with FCM only rejectable or -6dB indications need to be reported.

Yep, I do that all the time. It adds a little pizzazz to a boring report.

Although .... as long as you have a camera, it's much more fun taking pictures of welders in action.

Thirdeye, is that a Sitescan 240? Personally I like the green on black display. Nice action shot! MR

From the '05 date on the display, I'm thinking that is a Sitescan 130. That is the only screen color option on that scope. I have a 230 that has 8 or 10 options for colors.... but I seem to always go to the orange on black. Like Baskin Robbins, the choices are neat to look at ... but I always wind up going with chocolate.

~thirdeye~

If the client wants an examination record for the full length of the scan, then the client doesn't understand standard UT procedures. Do they want an "examination record" for MT as well?

Are you sure they're not just asking for an inspection report? What they appear to be asking for is far in excess of standard D1.5 doings.

Hg

This is referenced from a 2002 version of D1.5, (6.20.1 "A report form which clearly identifies the work and the area of inspection shall be completed by the UT technician at the time of inspection.") I did have a QA inspector question me about submitting a report "at the time of inspection". I explained to the QA inspector, that even though I carry in a binder with the extracted information from D1.5 I need for UT examination and a work form I use to log in rejectable and reportable indications, my formal reports are stored on pc and he would get them before the end of the shift. In this case there were 14 separate 6" stiffener to flange full penetration welds on 4 different floorbeams. Each floorbeam has an individual piece mark in which he would recieve 4 separate UT reports identifying 14 locations on each report. To scan a 6" weld and stop to tap out 56 individual UT reports would be crazy. Luckly, he agreed.

I think it's not unreasonable to interpret "at the time of inspection" to mean "don't try to reconstruct this from memory six weeks down the line". If at exact time of inspection you record enough information to be able to reconstruct a more formal report later, there shouldn't be any kind of problem. And there's still nothing there to imply a fully encoded scan would be required!

Hg

Absolutely, the only time I ever ran into encoding & recording a scan was with immersion UT for material certification or SNR determination.

I have seen that it is used for automatic scanning of phased array.

Dear HgTX,

Normally we will submitt the report and already prepared accordance with the D1.5 suggested format. End of the meetings with the contractor we agreed on Normal Ascan examination and report. Apart from this I am planing to submitt the A-scan in digital picture format for each reject welds.

Dear all,

thanks for your time and answers. Would you like to suggest A-Scan equipmet for this inspection. I am thinking to buy Epoch1000i it has AWS D1.1 and D1.5 calculator and base of PA scan.

jaws, Krautkramer and Sonatest have different model scopes out there with the AWS software installed upon request. I like the Sonatest because the menus seem easier to work with when changing setups. There are too many sub-menus that I don't like with the Krautkramer. I used a 230 Sitescan in the past where I could hook up a printer and print out the display or download the data onto a laptop. Currently I use a 240 Sitecan with the AWS software package which speeds up the evaluation process but I don't have any need for more bells & whistles. Why not contact a rep for each company and compare models? Might be able to get them to knock something off the price to beat out the other guy. MR

I have a sitescan 240 and a GE USN 58L. Both machines have software that allows the A-scan presentation (Screen Shot) to be saved and placed on the report as a JPEG. When inspecting bridge pins in accordance with ASTM A-388, my client requires me to submit a screen shot of the backwall reflection with the report. Since the UT operator does not have a detailed set of drawings for each Pin, often times the pins are compared to each other for evaluation. If there are six pins that appear to be the same length and diameter, but one contains an indication that the others do not, the screen shots will aid the client in determining whether the indication is relevant or not.

Powered by mwForum 2.29.2 © 1999-2013 Markus Wichitill