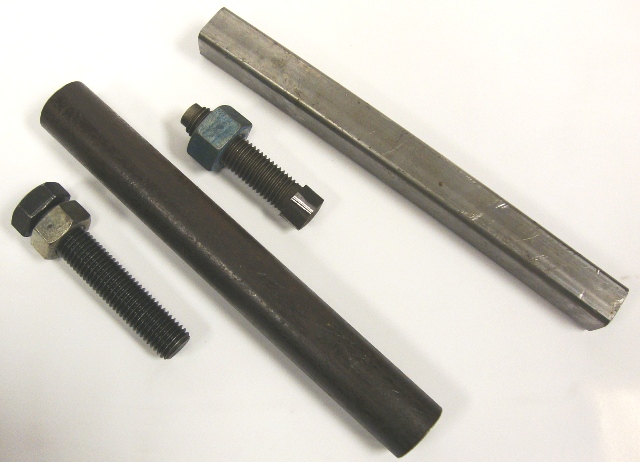

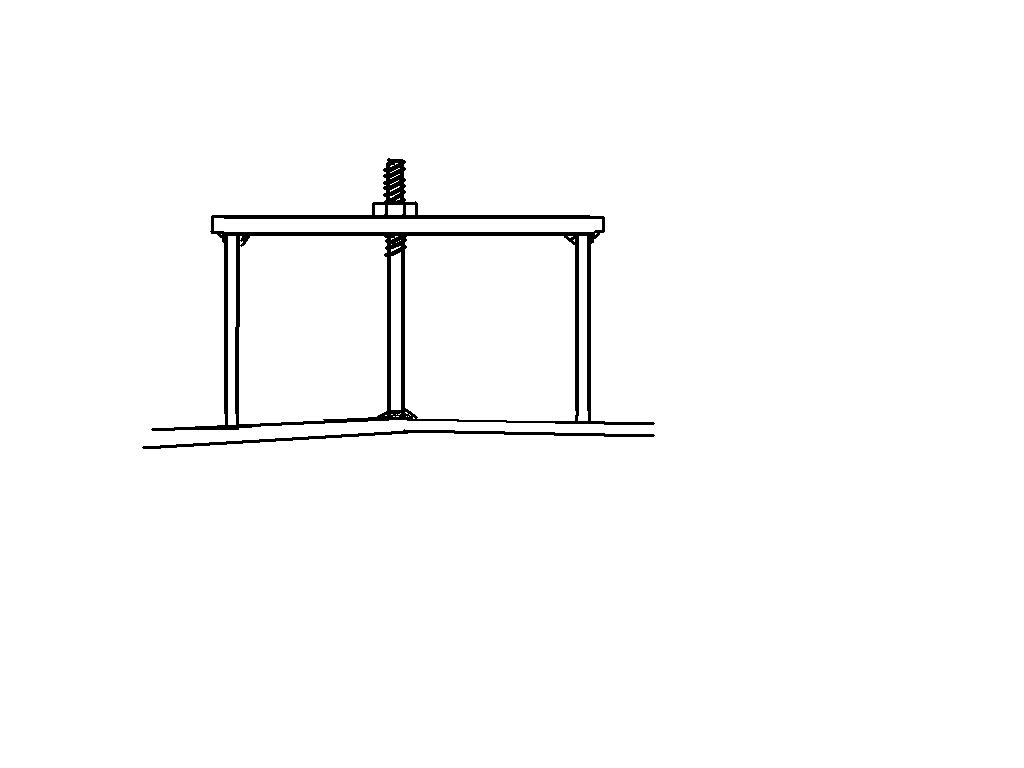

Hello folks, there are those times when you're fitting something up and it pulls in a bit too much and you possibly need a little something to spread it back out just a bit. In this case by using a bit of pipe or square tubing you can gain that little bit of an edge in adjusting the width without having to invest in porta-powers or other rather expensive tools. Either a bolt with full threads or a jacking bolt possibly can be utilized. Along with that, a length of appropriately sized pipe or square tube can do wonders for adjusting the width of your particular application. If you have various lengths of the pipe or square tube around you can be ready for just about any spreading challenge. In these two examples I have used a 3/4" jacking bolt and a 3/4" full threaded bolt, the jacking bolt in the square tube and the 3/4" bolt in the pipe. I prefer the jacking bolt and the 1" square tube because with a little bit of grinding on the square end of the jacking bolt the tube will keep the jacking bolt from turning while you are adjusting the length of it with the nut. I have included a couple of pictures to show the basic set-up and principle of this. If you have any variations of this sort of thing please speak up and possibly include some pictures. Best regards, Allan