Simply from your description of the application, it is a structural application. You are concerned that the wire ties might not hold up to the abuse of the handling, i.e., the structural loads due to the twisting and bending might part the ties.

ASTM A615 is not prequalified if my memory serves me correctly. That means the welding procedure will have to be qualified by testing. While I have a copy of the welding code in my office, it is not at my fingertips, and I am ready to leave the office for a meeting.

The nature of the loads while picking and moving the rebar cage places the welded joints in either tension or compression. The length of the welds are rather short and the unit stresses very high as a result. The failure modes will be cracking transverse to the rebar or shear through the weld.

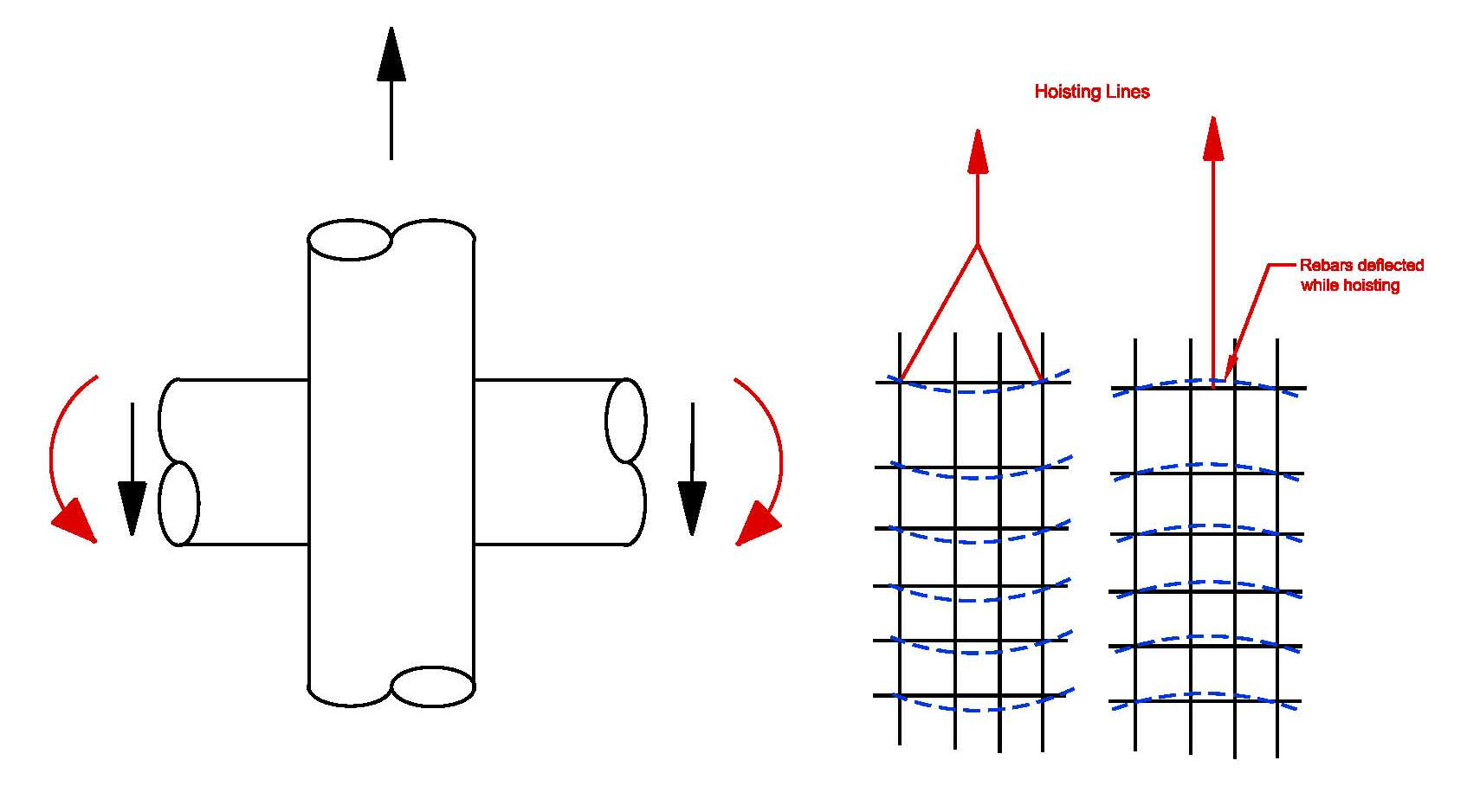

Consider a vertical bar, which will be the member to which the hoisting gear will be attached, directly or indirectly. A cross bar is welded to the vertical bar and weights are attached to the horizontal cross bar. The horizontal bar is bent downward due to gravity loads imposed by the weights (the weights would be the weight of the numerous rebars making up the cage). If the weight is distributed evenly so there is no eccentricity, the bar is subject to tensile and bending forces. Due to the high hardness of the HAZ, there is a high probability of the existence of an unfilled crater, some undercut, etc.; a transverse crack across the rebar can easily develop. If the load is greater on one side of the vertical bar than the other is, shear forces can cause the welds to shear. Remember that the welds are very short, most likely undersized, with a very hard HAZ with little ductility thereby allowing little elongation or plastic deformation to redistribute the loads.

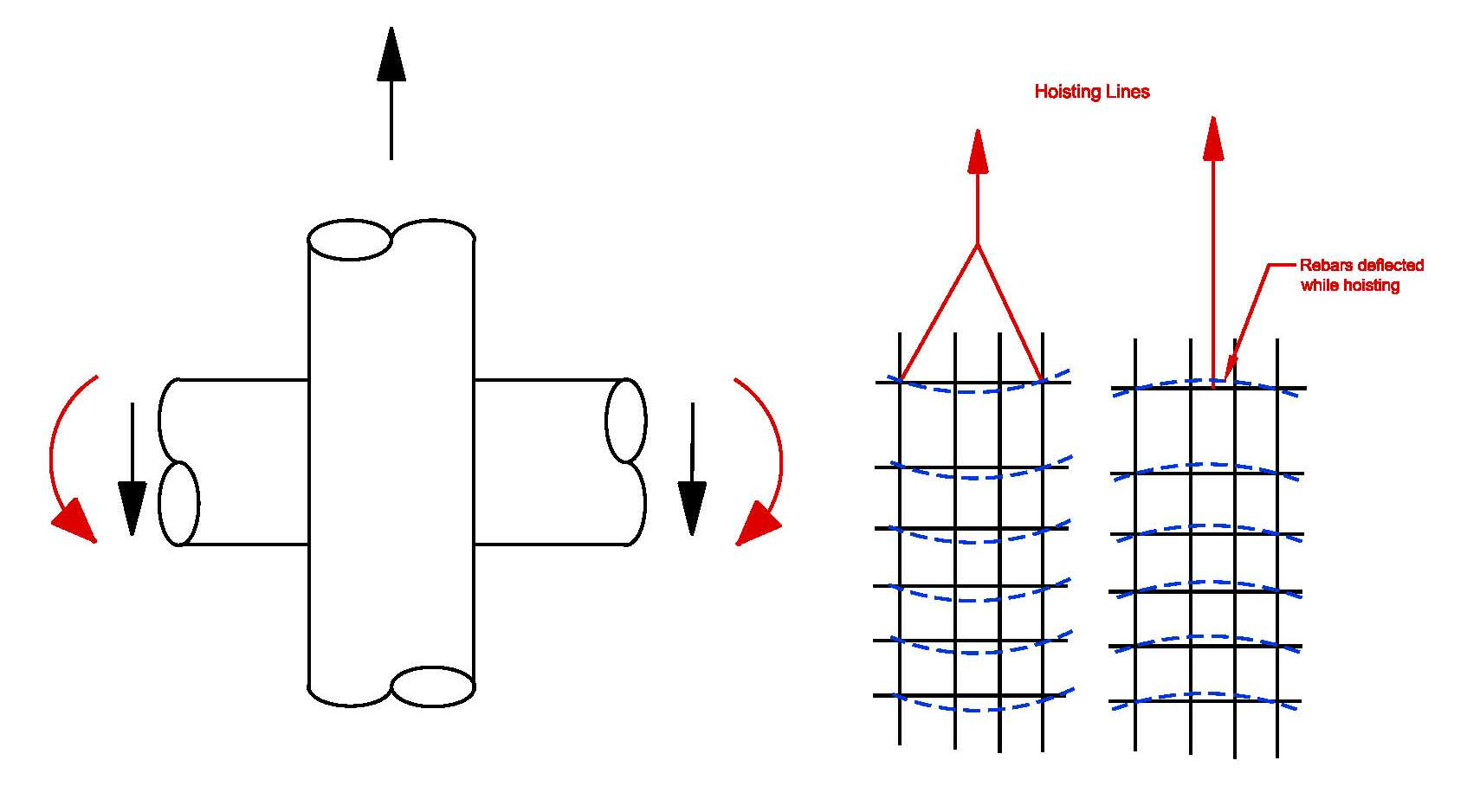

As the cage is lifted, the horizontal bars deflect thereby imposing a bending moment on the welds and a twisting or torque load on individual welds. The attached sketch may depict the nature of the loads better than I can describe them in text.

The use of wire ties allows the rebars to deflect, twist, and move. They do little to increase rigidity, as would the welds. At the risk of sounding like a heretic, more ties or larger tie wire would be the better solution in my opinion.

Best regards - Al

If you don't get the answer you want to hear you can always ask again and again until you do get the answer you want to hear. Sooner or later someone will say exactly what you want to hear.

"Mommy, mommy, can I put this fork into the electric socket?"

"No Johnny, you'll get electrocuted!"

"Jane, Jane, can I put this fork into the electric socket?"

"No Johnny, you'll get hurt!"

"Daddy, daddy, can I put this fork into the electric socket?"

"No Johnny, you'll get the shock of your life."

"Hey mister, can I put this fork into the electric socket?"

"Sure kid! Can I watch while you do it?"

Best regards -Al