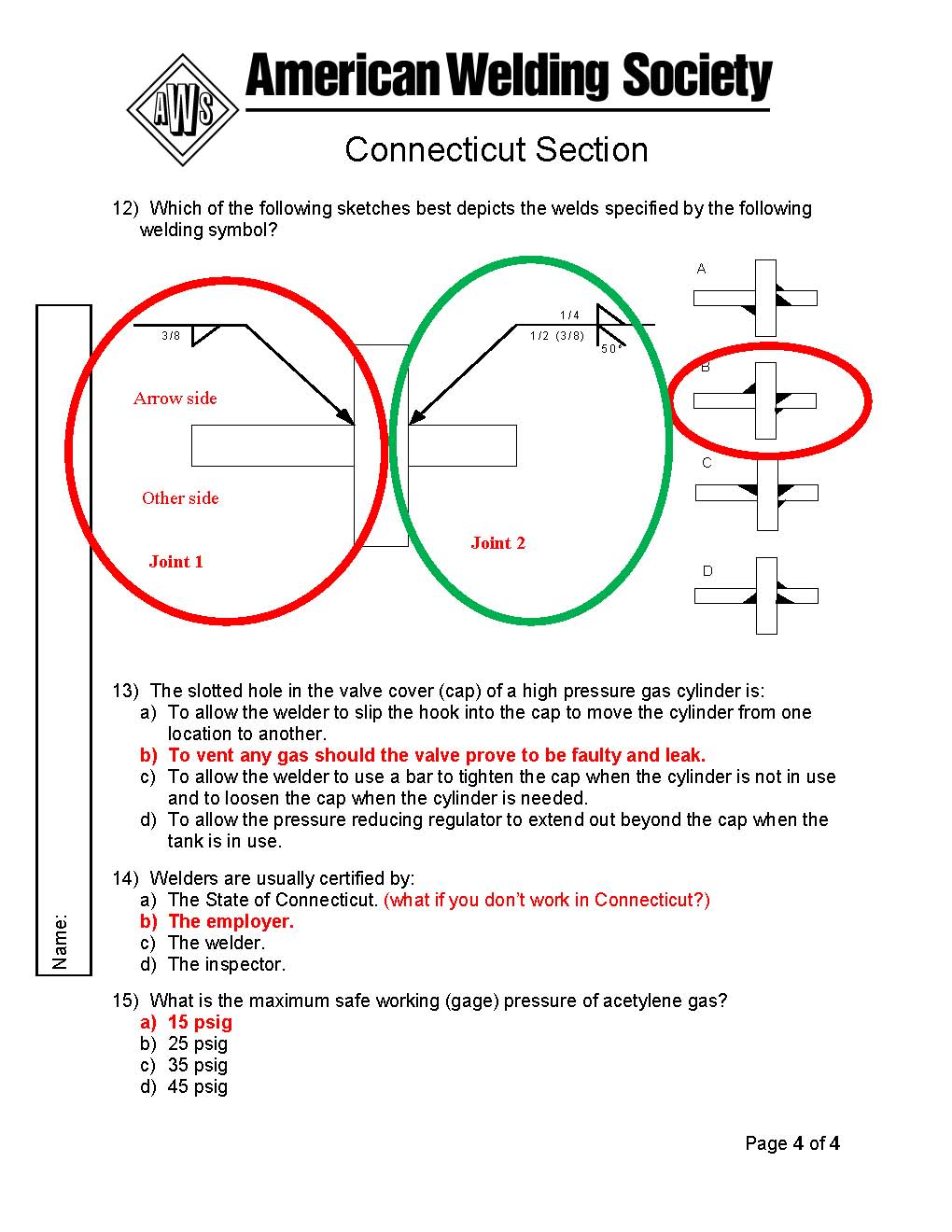

The object is to select the best answer from those provided.

Fewer weld beads (translate as thermal cycles) results in less distortion. How do you deposit a weld of a certain size with fewer beads? By using a large diameter electrode with high current and use a weave bead.

High interpass temperature means there is less thermal gradient in the through thickness direction as well as in the surrounding base metal. The concept of maximizing the thermal gradient is used to our advantage when cambering members or when straighting damaged members by heating them with a torch. To minimize the distortion (opposite affect as in the case of cambering) you want the entire cross section to be heated as uniformly as possible. Preheating will help minimize the distortion, but that wasn't included in the answer I selected. Where preheat was mentioned, it was in conjunction with stringers which is going to increase distortion due to the increased number of thermal cycles required to deposite the required weld size. The other answer that included preheat mentioned weave beads, but not high current.

You can try a simple experiment using the T-joint described for the fillet break test in D1.1. Place a small tack weld at each end of the T-joint (not in the area of the weld but, but on the very ends to hold the plates in proper perpendicular alignment). Weld a 3/8 inch fillet weld on one side of the joint in the vertical postion. In one case make the weld using a single pass weave bead. Weld a second sample using several stringer beads. Remember, the resulting fillet welds have to be the same size for the test to be valid.

There are many ways to mitigate the distortion; use strong backs, use the back step technique, minimize the weld size, don't over weld, etc., but they were not listed in any of the answers provided.

Best regards - Al