Chris,

I had to run a little experiment and then I keep getting interrupted trying to get back to this.

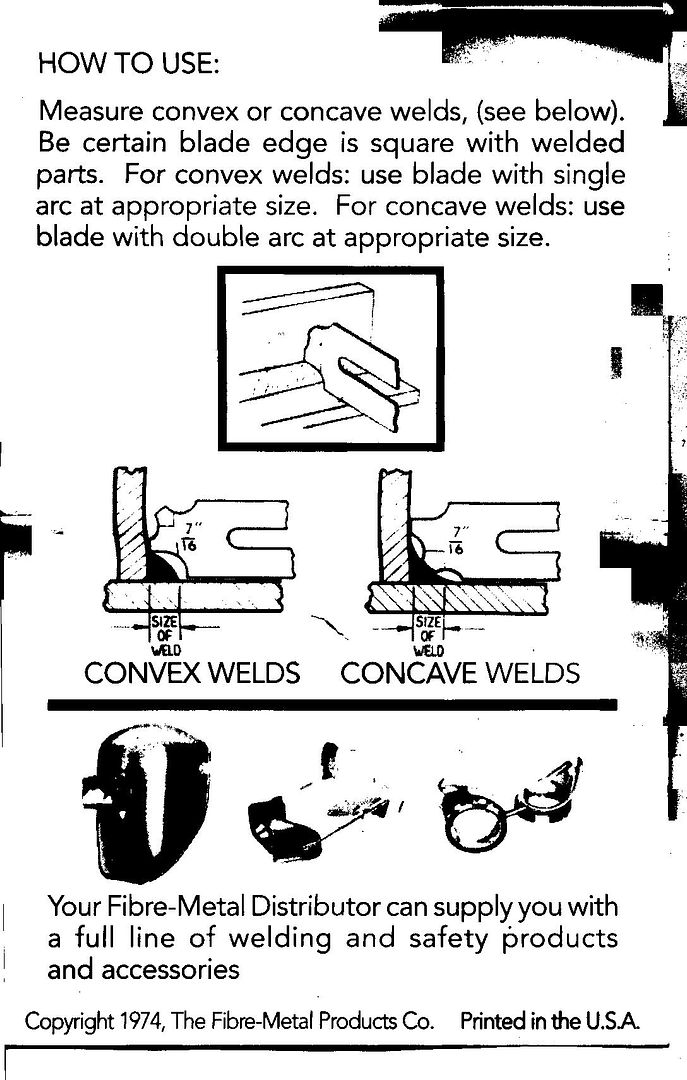

1) I would, for the most part, only check the leg size it the drwg is calling for 5/16" fillet welds and they are convex. But, I said for the most part, if the weld looks flat or is DEFINITELY concave then I double check with the concave end of the blade gage.

2) Now as to your trying to see how the blade compares to which throat- actual or theoretical, I ran some various sized fillet welds and ran some tests. My personal opinion is that when I compare a weld of ANY size with the concave blade gage it matches the bridge cam's 'Theoretical' scale throat gage. The 'Actual' scale would require even more weld. Not necessarily bad. Especially with this consideration:

D1.1:2008, Clause 2.2.4 (1) States- "For fillet welds between parts with surfaces meeting at an angle between 80* and 100*, contract documents shall specify weld leg size."

From the 3.0 definition of a Fillet Weld and all applicable references it must be at least flat, and preferrably slightly convex, across the face to be the 'triangle' with the called out leg measurement.

From this I note: a) a 5/16" Fillet weld with a slightly convex surface will meet all requirements when examined with a blade Fillet Weld Gage for convex welds; b) when double checking the throat with the 5/16" concave blade it is really large enough, not even a question; c) When checking a Fillet Weld with the correct leg size BUT with a concave face the 5/16" concave blade will not touch; d) By the time the weld is large enough to touch with the 'Theoretical' throat Cam gage or the concave gage of the blade gage it will be about twice the leg measurement as was called out; e) when using the 'Actual' scale it would be even larger because even more throat is required to touch the point of the gage to get your measurement;

Thus: If I use the 'Theoretical' to measure a concave fillet, then compare it to the 'Actual' I can have a fair APPROXIMATION of the true size of the fillet weld including penetration. But, unless a concave fillet is called out, the most accurate and only meaningful measurement is rather the leg length is Acceptable and the face is at least flat so that the enclosed triangle is of the size required by the engineer in the contract documents/prints.

Do this, take a piece of paper, draw a 'T' joint, take your blade gage for any size weld, trace around the convex end, now trace in the same area around the concave end. Is the 1/2" concave fillet going to give you anywhere close to the right weld for a 1/2" convex/leg length fillet? A 3/4" concave fillet is just enough weld for a 1/2" convex weld. And that's equal to about a 7/8" leg. That's a lot of difference. Then if you go by the 'Actual' scale you would have them adding even more.

Bottom line, not sure why you would double check a true convex fillet with ANY concave scale gage. Don't think it really accomplishes the proper or desired end result and it doesn't really matter rather you use 'Actual' or 'Theoretical'.

Think I drug this out enough. Hope I made sense. Just my two tin pennies worth.

Have a Great Day, Brent