I have a question about welding cement lined pipe. I have a customer that is needing a new flange put on an existing line.

He was telling me a little bit about it. He talked about placing a gasket in between the pipe and the flange that is to be welded, holding it in place with elmers glue or something of that nature and then welding the flange as you would normal pipe. This is a bit confusing to me because I have never done it of course but how do you keep from burning up the gasket and damaging the concrete while welding. Any input or procedures would be greatly appreciated.

Thanks

First why would you put the gasket in while your welding. Second they can grout back in any cement liner that is damaged after you make your weld. But still the gasket thing really confuses me maybe I am not understanding the repair. In a normal situation you would make up the flange do the weld then open the flange surfaces back up with a wedge and slide the gasket in.

I agree with johnyutah regarding the flange welding. I suppose it's a slip on flange, right?

I don't believe the concrete will be greatly damaged after welding. In my opinion, the concrete will withstand, if not perfectly at least acceptably, the welding. There's always the chance, as johnyutah pointed out, to grout up the concrete. The grouting must be carried out carefully, otherwise it won't stick onto the existing concrete.

Giovanni S. Crisi

Sao Paulo - Brazil

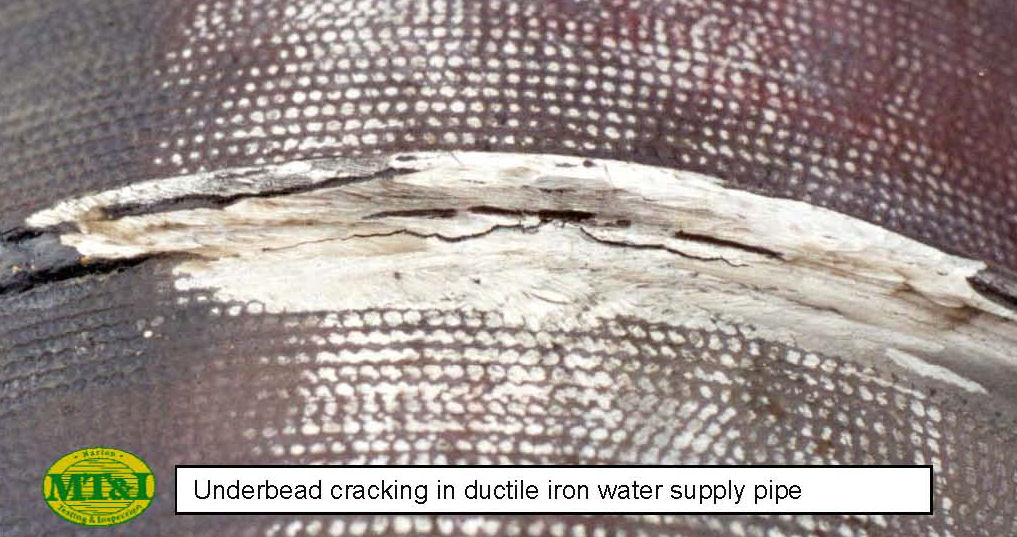

One additional point not mentioned is that cement lined pipe is typically ductile iron. Ductile iron is innoculated and held at high temperature to cause the graphite in the cast iron to form nodules (of graphite) in a ferrite matrix.

Welding the ductile iron pipe can cause it to revert back to a "cast iron" that is brittle once again.

A quick search of the internet will yield several interesting articles and recommendations for welding ductile iron. Here is one you might find useful.

http://www.dipra.org/pdf/fieldCutBrochure.pdfBest regards - Al

We live in different countries, Al. Here in Brazil, concrete lined pipes are made from rolled, ERW carbon steel pipes.

They work at ambient temperature and low to intermadiate pressure. Of course, they carry neither steam nor hydrocarbons or other chemicals. They're used mostly to carry sewage or rain water, that is corrosive to carbon steel but much less corrosive to concrete. The lining thickness is a few centimeters, so before it's completed corroded many years will pass. As for external corrosion, they're coated with a

suitable external lining.

Giovanni S. Crisi

You make your fit up as normal. Then you take a piece of gasket material and make a ring that you slide into the pipe. I have seen garlock or non-asbestos gasket material used in the field, but there is a company that makes the gaskets.

All it is for is to minimize the damage to the concrete lining. The gasket material get kinda burnt up as you put in the stringer. On a flange, you remove the gasket but on field lines, it gets left in.

Keep the heat input down. Wait 3-5 minutes before running the HP and 5-7 for the fillers and caps.

Don't sweat it. Once you get the idea how to slip the gasket material in, it is easy. I have seen guys try elmers, but 2 good wraps of gasket material will stay in place.

Salt water injection line or CO2 recovery?

I've welded LOTS of cement lined pipe,it was for firewater service in a refinery,it cuts really good with a plasma hooked up to an oki beveler,zip around semi quick and smack it with a hammer for a clean break on the cement,for slip ons we'd chip/grind the cement back by scoring it with a 4 inch grinder,hammer,chisel,weld the flanges on and then repair the cement with something the laborers called "Moose Milk" and jet set grout.The fit up on but welds was slammed together with an 1/8 inch landing and welded up,the X-rays had to show that no penetration had occured.The cement is really not cement per se,its kind of got an epoxy type of feel to it and if you blow through it melts and makes a hell of a mess.The pipe we used was SCH 20,the cement was 1/2-5/8 thick and I ran 1 really fast one down to seal the crack shut then another 5/32 down and an 1/8 inch 7018 up,rollouts were 7/32 7018 over the pisser pass.Like as mentioned before pre exterior plastic coating on the exterior,hand wrapped the joints,.......all 14 inch mainline.Judging from the original line it's a really good choice for that service,the tie ins showed that the pipe was like brand new between the cement and the pipe,still shiny clean with the sandblasting profile required to make the stuff stick and stay put.Downhilling it is the only way to go on the first 2 passes IMO,