The PIPE FABRICATORS Blue Book , by Graves, has sch 10 (.250) figures. The Pipe Fitter's and Pipe Welder's Handbook by Franklin explains how to make a branch fitting (among other things) with no measurements from a table.

http://www.thegangbox.com/c-154-pipefitterswelding.aspxThose two books and The Pipe Fitter's Blue Book by Graves are must haves IMO. I also like the one Pipe Handbook for Pipefitters & Welders ULT-3

By R.L. "Bulldog" Eisenbarth. it has some of the layout measurements that the other two books don't have. Like mitering pipe dimensions etc. Although a lot of the info is a repeat of the other three books.

I had to make two field fabricated "Y"s for a chill water system last week those guys looked at me like I was from Mars when I got done. Felt good like an old school pipefitter!

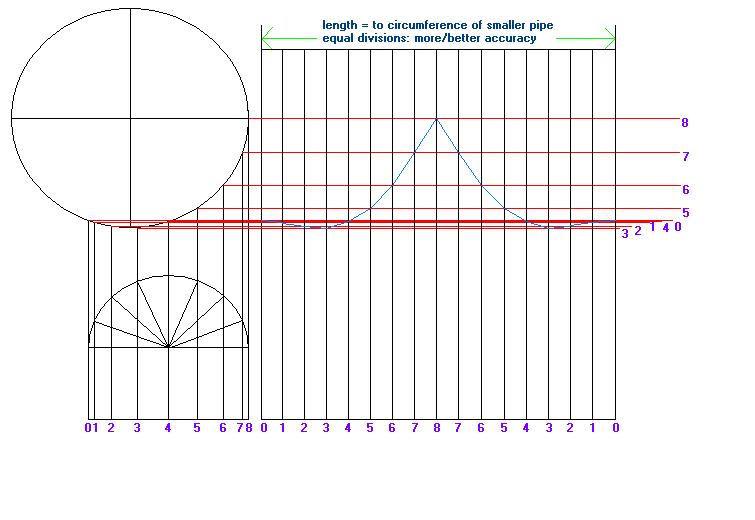

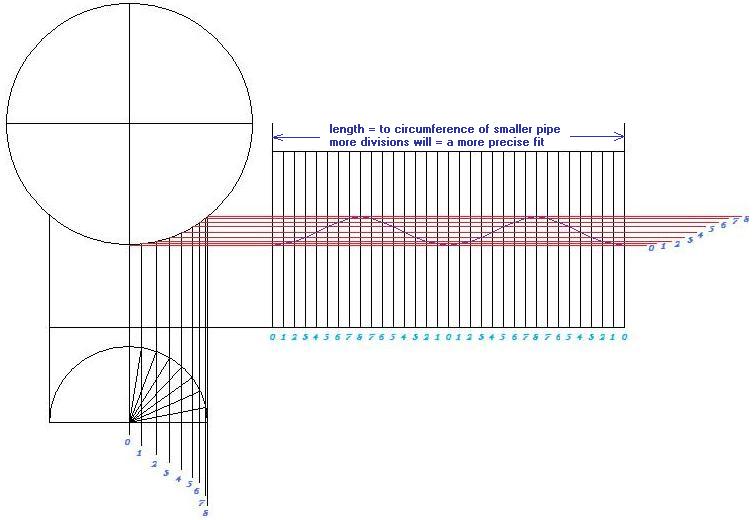

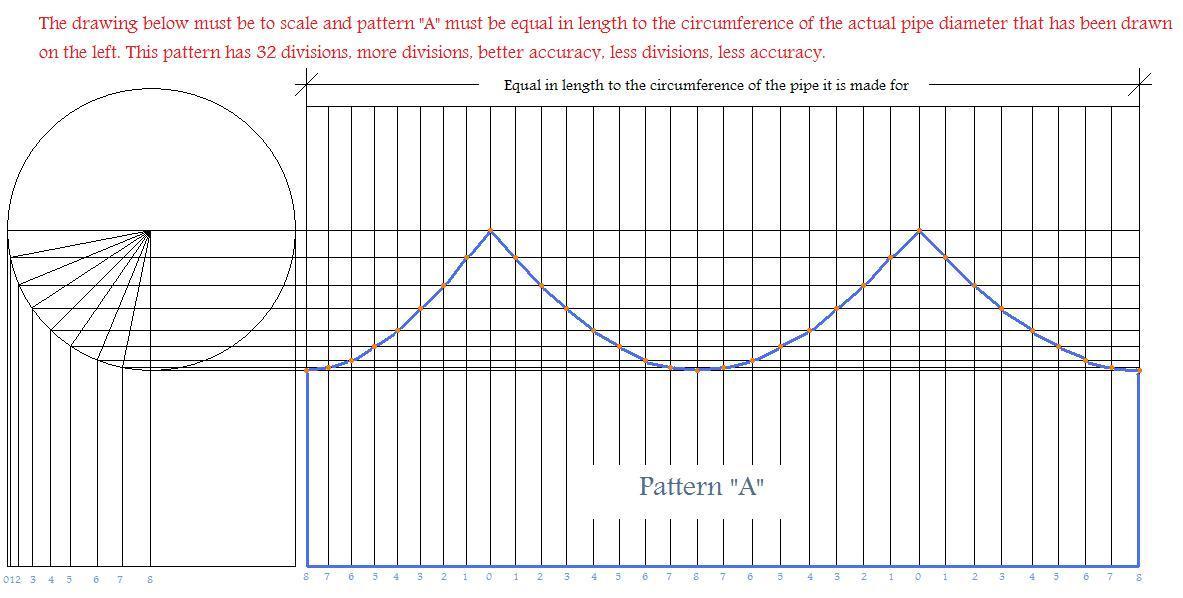

I think it is a good idea to pick up drops from jobs you are on no matter how small. They are great to practice a "Bull Plug" cap or branch fitting or a lateral. I like the method Al showed too. After you do one or two it gets easier and you can make any branch or any degree lateral if you have a big enough piece of paper.

http://industrialpress.com/node/610 Pipefitter's Handbook. It is a larger version of the Franklin PF and PW Handbook, and has examples of how to do it Al's way. That is how I taught myself.

Making pipe patterns got to be kind of a hobby for me while I was working out of town for the week. Keep me out of trouble too! I always carry a Mathey Dearman #DK-239 - Small Protractor (18" / 457mm), a compass, and a set of plastic French Curves and poster board in my Rig. If you get the protractor, I added the metal disk from some Fibre-Metal head gear under the nut on it so you can tighten it better. The way Mathey does it it will not tighten all the way.

Well worth the time to try a few "just In case". You never know when you might need it!