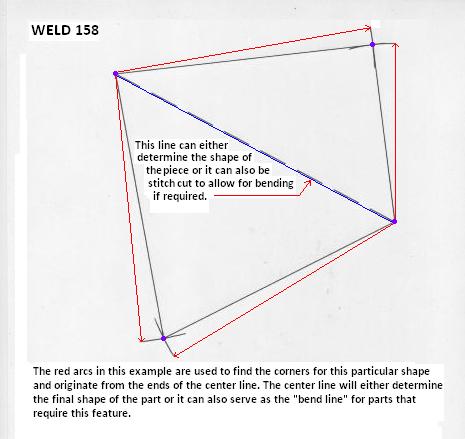

Hello folks, it is very common to utilize triangles, circles, radius's, for layout and fabrication. In the particular area where I live there are still a number of sawmills, pulp mills, and other industrial facilities that deal with various products that are conveyed from different points to particular destinations. In the following examples/photos I have included some techniques for dealing with enclosing and directing product when such a need exists. You might possibly have a piece of equipment overhead that gives off or makes scraps or other wastes that fall to a conveyor system or some other sort of removal system below. By taking measurements to provide layouts for various triangles you can readily deal with this task. When I have needed to deal with this sort of challenge, I start out with a scratch pad, a tape measure, and possibly a helper to aid with measuring. After carefully taking measurements, considering size, thickness, and weight of pieces I will go to measuring and cutting the materials to complete the job at hand. Most of the time something like this cannot readily be dealt with prior to installation of the various equipment and must be taken care of by the installers. I refer to this as slope sheeting, I'm sure others of you know this by a different name or description. When something overhead is located in-line with the item underneath it is somewhat simpler to make this work, when the items are skewed on one or two axis, this method can be really beneficial. If two triangles are required to make the transition(as in the example that I have included), you may wish to stitch cut the seam that connects the two triangles to simplify installation and reduce welding and hold shape better. Thickness of material may have a large bearing on your particular choice. So anyway, here goes. Best regards, Allan

EDIT: Sorry, I did screw up on my parts on the 3rd picture, the actual pieces are done from opposite corners