By 803056

By 803056  Date

Date 03-26-2011 16:15

Edited 03-28-2011 13:00

I've used the "buttering" technique Joe has mentioned on numerous occasions with good results.

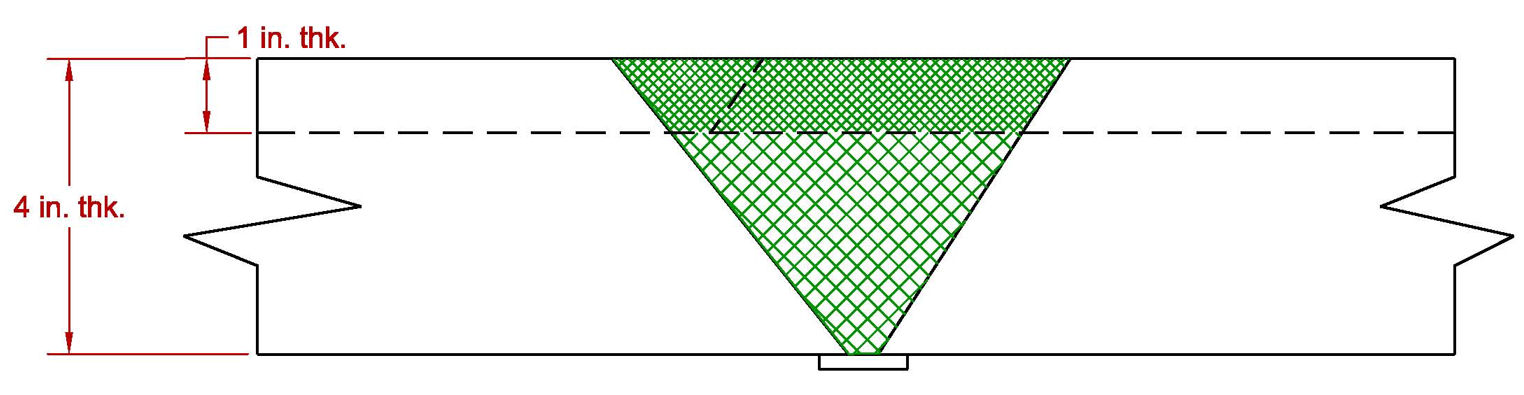

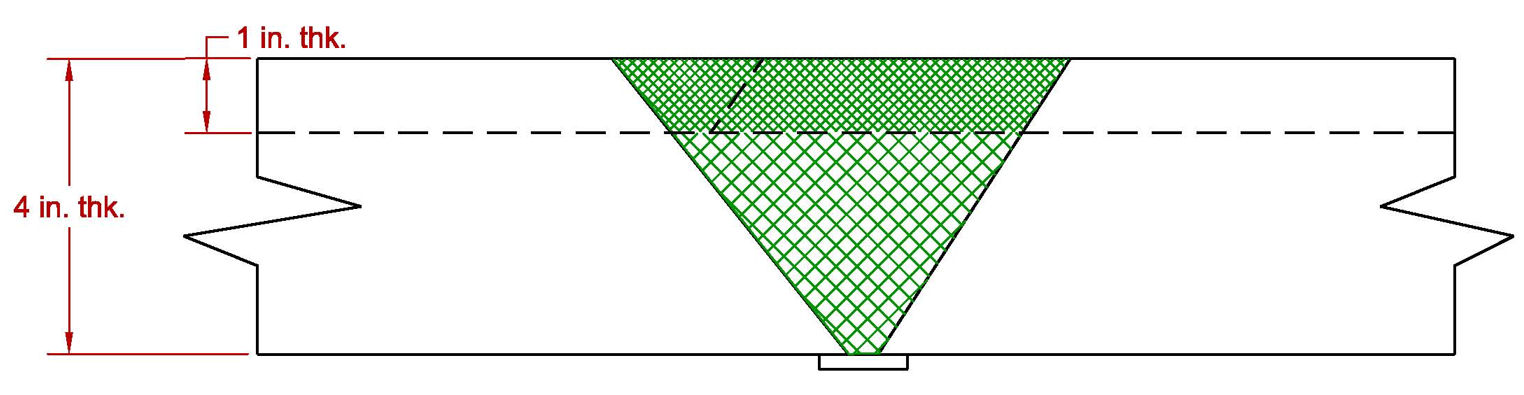

From a practical standpoint, there is no difference in using the buttering (a surfacing weld) on 1 inch plate to reduce the root opening and welding a very thick joint. The weld deposit is often overmatched and as sound as the base metal if the welder knows how to weld. Limiting the discussion to low carbon and high strength low alloy steels, the properties of the weld often are better than the virgin base metal with regards to UTS, YS, and ductility. Consider the attached sketch. Is the "soundness" and the mechanical properties of the 1 inch thick plate with the "repaired root opening" any different than the welded V-groove in the 4 inch plate? Let's not forget that the requirements of D1.1 must be met if that is the appropriate welding code. Under the auspices of D1.1 the Engineer would have to approve proposed repair if the root opening exceeds that permitted by clause 5.22.4.3 and inorder to comply with clause 5.23.4.4 (D1.1-2010).

The technique can mitigate the potential for lamellar tears if the surfacing weld is deposited using low hydrogen deposit on the member most likely to suffer lamellar tear. The surfacing weld can be used to reduce the root opening, but the secret is to deposit the weld on one or both members without tying the two together until the corrective work is completed. The idea is to deposit the surfacing welds while the joint is unrestrained. This technique can also be used when joining two materials that do not play nicely together (think copper alloys joined to carbon steel or high strength low alloy steels) where the surfacing weld consists of several layers of weld metal that is compatible with the copper alloy and the carbon steel or HSLA steel. The transition layers must consist of a few layers to reduce the dilution to the point where the chemistry of the deposit is suitable for the closure weld.

Good luck - Al