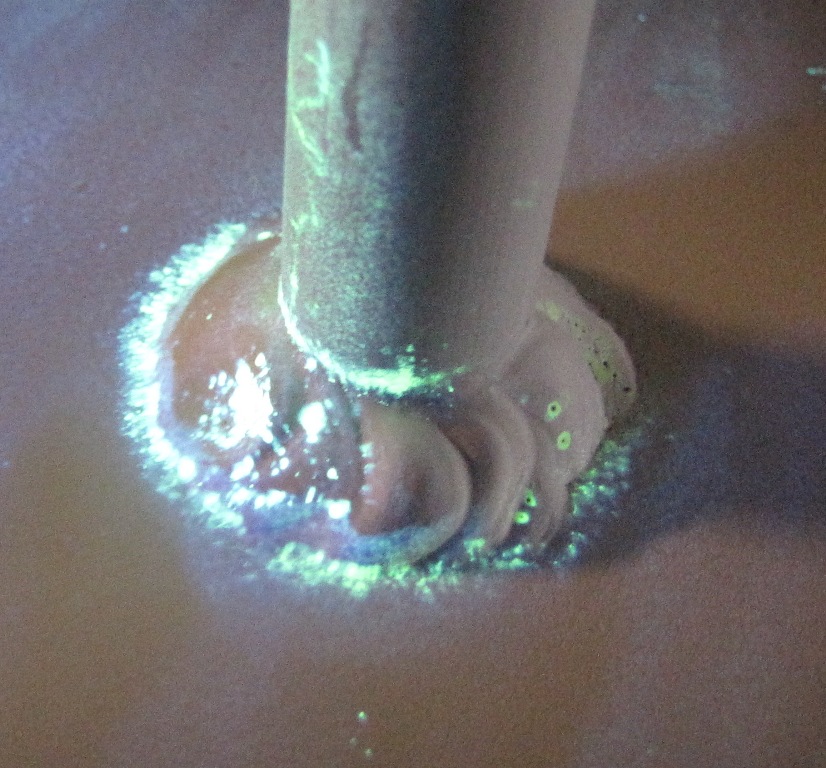

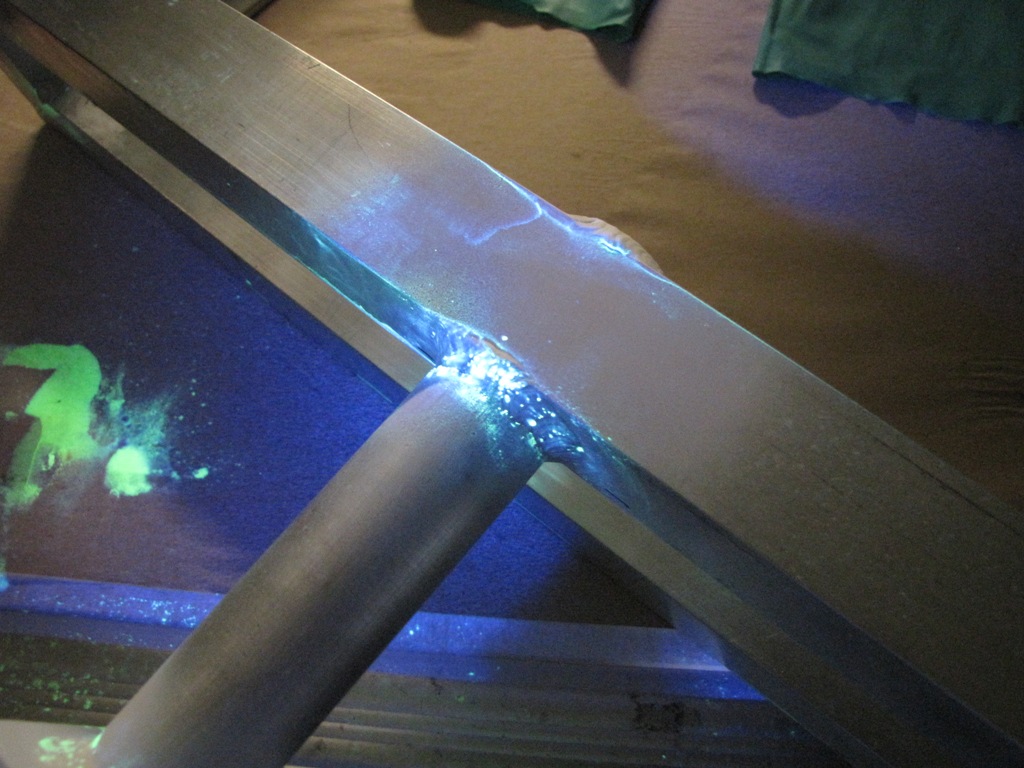

Aaahhh, I see, nothing wrong with practicing. However, and please forgive me, I was looking at the weld in the last pic, and still the developer is a little thick. Assuming you are using a non-aqueous wet, you dont need a "coating" but more of a "dusting" plus cleaning a weld, especially aluminum, with a power tool will mask indications. Did you chemically etch the weld prior to PT or is it just that you are using these pieces for practice?

When any type of mechanical removal of paint or material is done with softer metals, you should properly etch to remove any smeared material, usually 0.0004"-0.0006".