1.6mm gap? You gotta be kidding?

There is no requirement before or after welding. And especially with after welding you get what you get. You cannot control shrinkage that way.

The usual procedure is to either use gapolets or some such thing, or tilt the pipe on fit, tack one side, and square the pipe up and tack the other.

Viola! Gap.

Its not that technical.

I have verified that the gap remains after welding from RT and also from VT when the pipe fitting is small enough to check (by finger nail and/or inspection mirror).

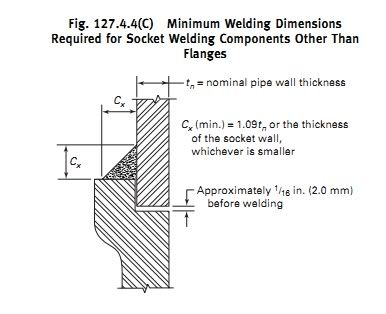

Common practice I have seen is to place pipe in fitting (example: 90 deg elbow) butted up, draw a line around the pipe, then withdraw pipe a min. of 1/16", place first tack, straighten pipe and place second tack, then while "hinged", rock pipe to 90 deg of face of fitting and place remaining two tacks.

I have personally seen where 50# steam lines of a common make-up warm air unit in the sub floor of paper machines have failed because there was no room for expansion. In 1992, one make-up unit in particular at a local Weyerhaeuser paper mill had 23ea (2" dia) socket welds fail at the toe of the weld because of this. These welds were made during a shutdown just a week before. Will try to round up the pix for your perusal.

[/img]

[/img]