Tyrone,

OK, I’m usually wrong at least once a day, but with further reflection, and a quick perusal of A2.4 … I’ll stick with what I wrote initially.

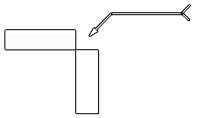

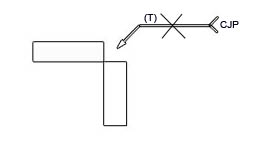

It seems to me ‘your’ symbol denotes some type of “edge preparation” … I.E. Bevels.

Now, if that’s what the ‘AWS technical review board ’ says to use, who am I to argue?And, if it wasn’t crystal clear in your WPS (as none of us have seen it), I’d sure as hell be making a call to the EOR!

But, that’s just me… Trying to get it right the first time!

Oh, and next time I’ll check previous postings … RE: Tyrone, 04-07-2004

Cheers,

Jb

The debate comes up now and again around here.

The debate comes up now and again around here.