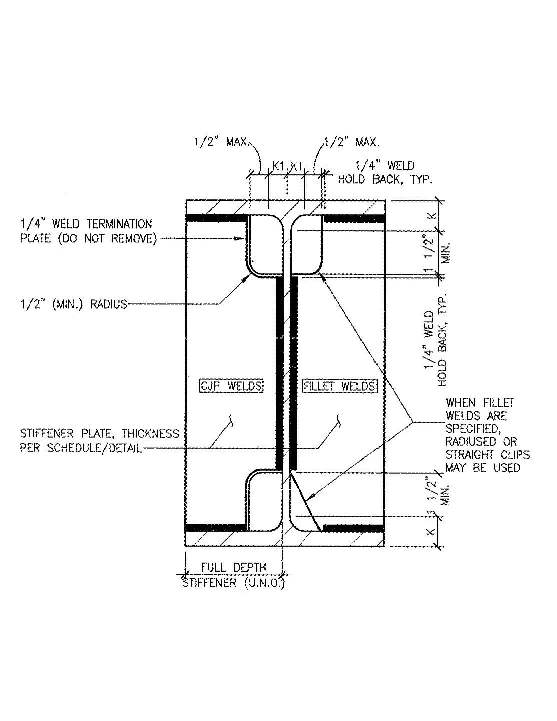

If you notice on the right side of the beam, there is a hold back for the weld termination point. This is most likely to prevent the development of a stress riser, if the weld were to terminate at the corner. For what ever reason, the engineer needs the welds to travel the full length of the stiffener on the left side. To prevent the development of a stress riser on the left side, the engineer has designed a plate for the weld to tie into. My question would be, how wide is that termination plate suppose to be.