The applicable welding standard says what it says. If the standard says the weld can be 15% undersized, that's what the criteria is.

To be specific, the clause you cited is

(5) Underrun (Undersize)

Fillet welds shall be permitted to be undersize by 15% or 1/16", whichever is

less, provided the undersize condition does not exceed 10% of the weld length.

My understanding would be that the criteria applies to any fillet weld where the size is specified on the drawing or other working document. In your case, the 6 mm weld could be as small as 5.4 mm provided the undersized portion of the weld is not more than 10% of the continuous weld length. I don't think the intent is to apply the 10% length to the total weld length of an intermittent weld (all increment lengths added together). I would apply the criteria to each individual increment.

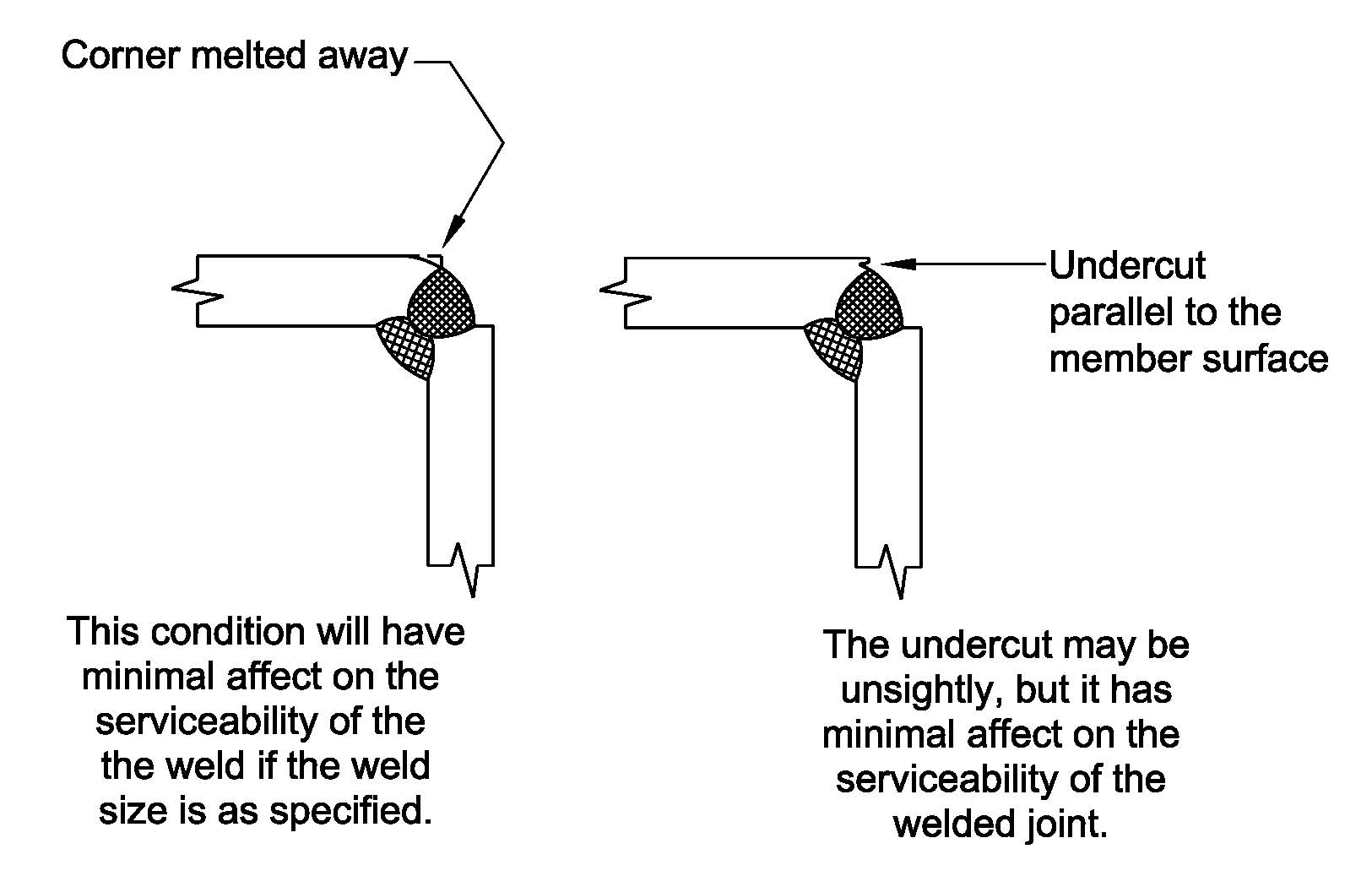

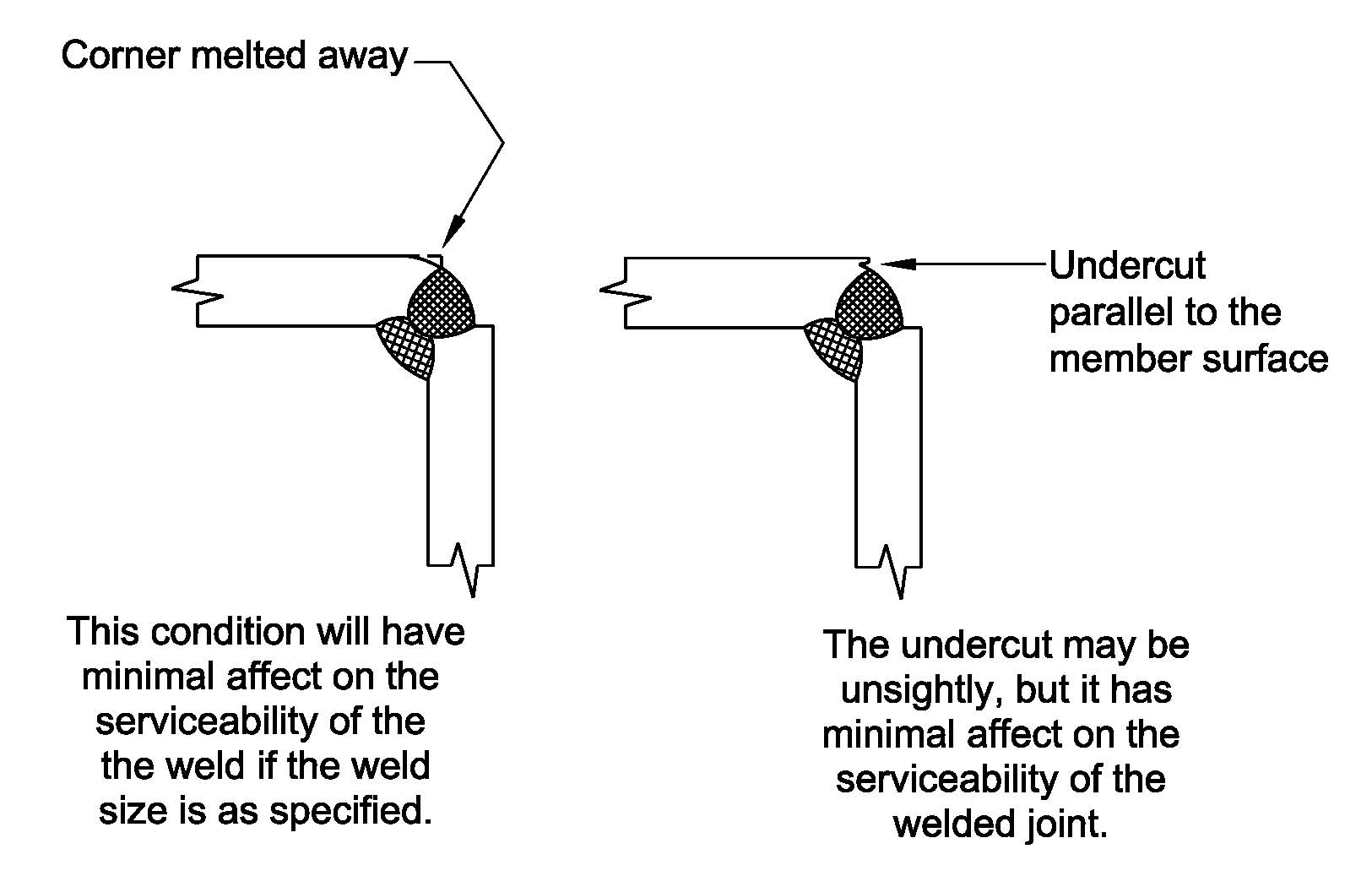

Undercut can easily be confused with what some welding standards refer to as edge melt, i.e., the edge of the plate is melted so there is no edge or lip at that point. In my humble opinion, the undercut is measured at the toe of the weld and the measurement is perpendicular to the surface of the base metal where it occurs. In you case if the undercut is at the toe of one of the intersecting members, but the depth is nearly parallel to the surface of the member, it really doesn't affect the integritty of the welded joint.

Hope that helps you.

Best regards - Al