Oh, no -- no. I'm not speaking about a specific drawing.

It's just a talk in general. I will translate it orally and also in writing and only sometimes in drawings.

I'm trying to find an appropriate term and just collecting the info to hit the "bull's eye".

What I said above is just a description of what I heard about this weld on the Russian side.

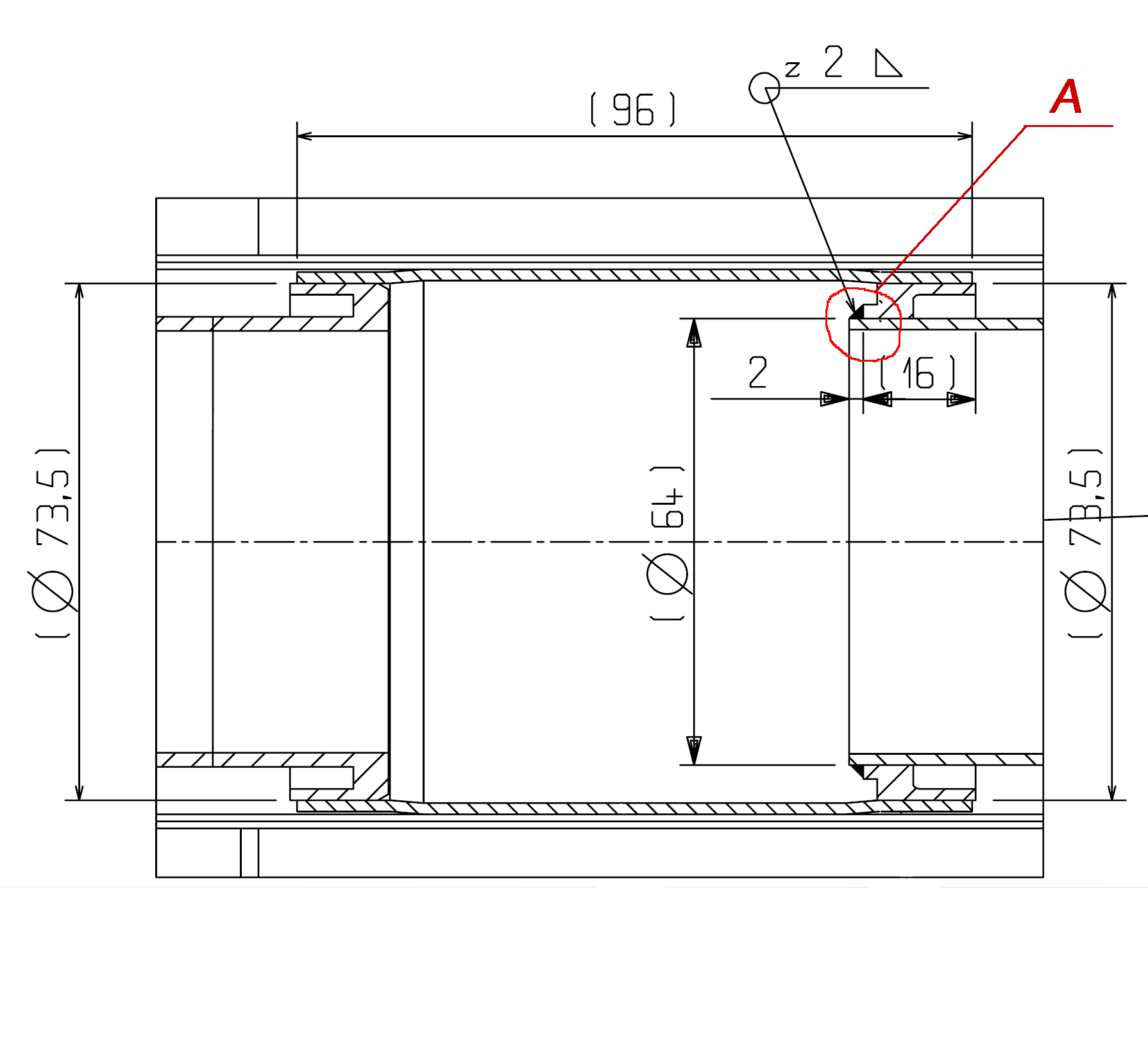

They do not specify penetration, or beveling or anything. Rather they draw a pic and show a ridge on the rim of a flange and call it "oos" in Russian.

So there is a single term for that weld in Russian "oosovy shov". Very simple -- problem to translate...

How wil I translate it all just in one word????

How wil I translate it all just in one word????