Hi vdao

From your posts, it sounds like you are repairing casting defects. One of the problems with castings is that they are often "dirty". (Probably why you need to perform the repairs in the first place.) Because the GTAW process has no good mechanism for removing contamination from the weld pool, it is less resistant to welding contaminated base materials than the fluxing processes such as SMAW or FCAW. For this reason, you would not normally want to use GTAW for the repair process.

Just a matter of clarification to your first question: Are you actually repairing a Monel casting with the Monel filler?

I have not welded Monel M35-1 castings myself, but from what I can see, it is similar to the Monel 400 material, with a couple of changes to make it easier to cast. Here using the standard SMAW consumables for welding Monel 400, (A5.11 E NiCu-7) should work well. Again, if the casting contains relatively high impurity levels (particularly S; P; Pb) then you are going to have trouble with hot cracking of the welds.

Also just make sure that you are keeping the weld area and consumables clean. (e.g. Make sure that the excavated area is properly cleaned of DPI contamination, oil etc.)

Regards

Niekie

Niekie,

To answer your question : you actually repairing a Monel casting with the Monel filler? yes.

We do want to repair the casting , but we do not have a much luck with it, the cracking problems is very hard to control,even our foudry could not do it very good, and according to Mtl- Spec when we order the casting we must test for weldable. when we weld the forging or Bar component to Casting we always see cracking on casting part, so per recommendation, I will create WPS with FCAW/GMAW. And why M35-1have P43 per ASME Sect II B, and Monel 400 is P42 ?

Thanks,

Hi vdao

I would not use GMAW, but FCAW or SMAW for the repair. I am not sure where you got the P43 classification from, because ASTM A494 Gr M35-1 is not assigned in ASME IX. (Which is where the P number listings originate.) It would definately not be similar to a P43 classification, because P43 is primarily Ni-Cr-Mo alloys, whereas M35-1 is a Ni-Cu alloy. It is unassigned, but similar to P42. We must just make sure that you are in fact talking about the same alloy!

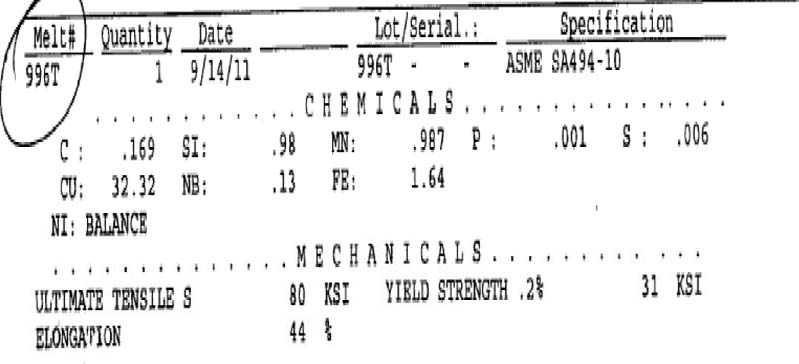

Hopefully you have received a material chemical analysis for the casting. Can you tell me what that analysis is? Specifically, also include the "trace elements" such as S & P content. Nickel based alloys can not handle high impurity levels.

Also, confirm the material grade of the bar / forging you are welding to the casting, and give the material specification for the filler you have been using so far.

Regards

Niekie

Nieke,

According to section 9 ED. 2011 is specified P43 at page 97, it is surprized me when I saw it, our supply foudry' metallurgists told me that, it can caused by cooling speed after heatreating or welding. And the trace elements" such as S & P content are in the Code range, we do not know why? I do not have a copy of CMTR now, and how to attached to forum.

And here are base mat i nour WPS:

SB-127400 to A-494 M-35-1,SB 164 Gr. 400, we are using ER NiCu7 forfiller matl., I can see the problem now per your recomendation because our WPS only qualified to use GTAW.

Regards

Hi vdao

I am not sure if your ASME IX is different to mine, but the only A494 alloys listed are: CX2MW (P43) and CW6M (P44). Grade M35-1 is not in my ASME IX. I will attach the relevant section of the P No listing showing this. It is for this reason that I asked that you make sure if you are welding the correct alloy! If you showed us the material analysis, we can make sure exactly what it is.

Regards

Niekie

Hi Niekie ,

You R right about the P number, and finally, I got the copy of CMTR from our supplier, I will attached it and please give an advice.

Thanks,

Hi vdao

The analysis looks like it should not be too difficult to weld, although there may be other impurities not analysed for. Hopefully if you use a fluxing process (e.g. SMAW) this should solve your problem.

Let me know how you progress.

Regards

Niekie

Nieke,

I will let you know as soon as I create a new WPS with FLAW/SMAW process, as it know we only use GTAW.

Regards,

V-Dao