The PQR is the "proof" or demonstration that what was done to weld the test coupon produced acceptable results, i.e., a sound weld with the appropriate mechanical properties. As such, you are establishing the parameters of what will and will not work.

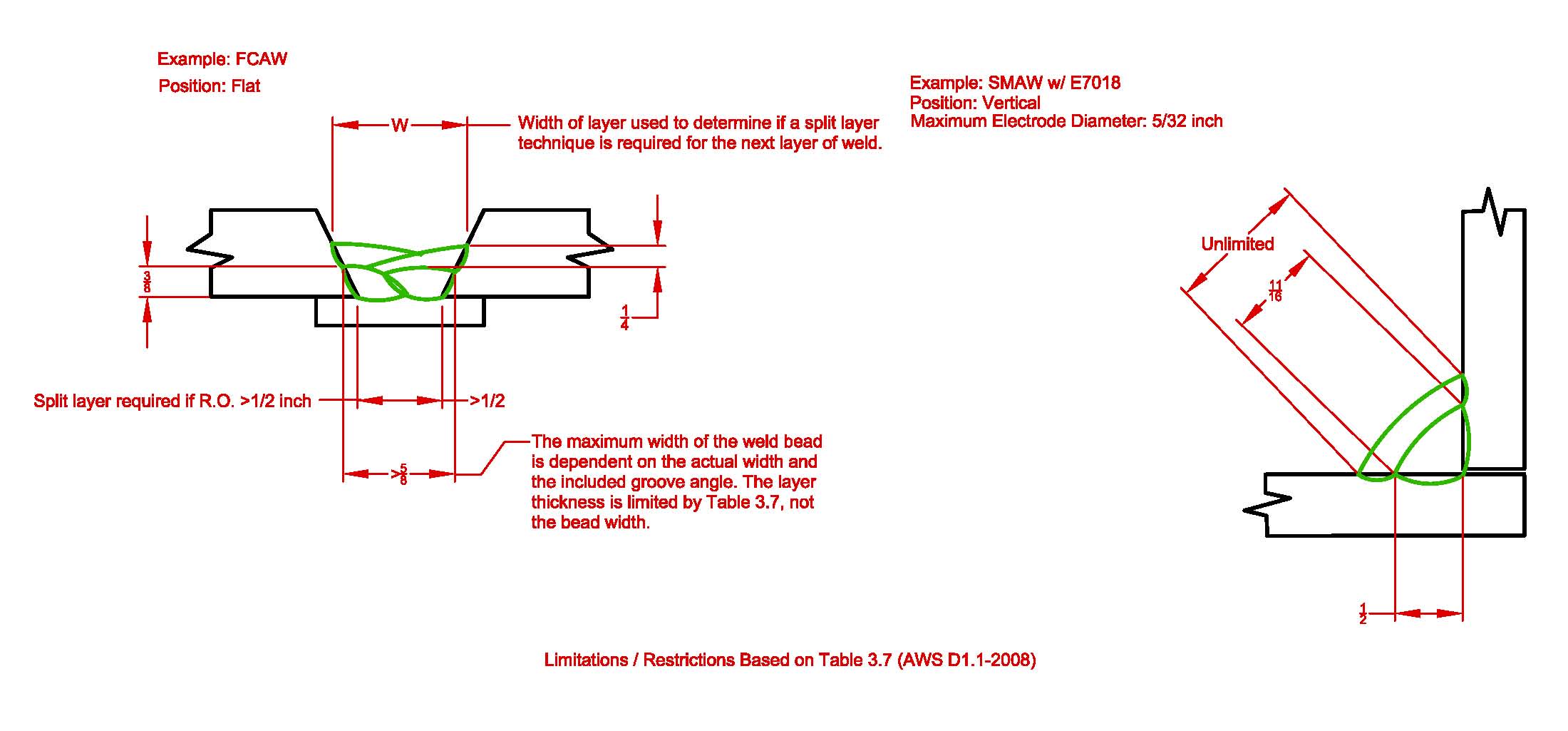

The requirements of Table 3.7 only apply to a prequalified WPS. Any restrictions or limitations apply if the procedure is prequalified and no test sample is welded and subjected to testing.

You can do whatever you want if you are qualifying the WPS by testing as required by Clause 4. The limitations of Table 4.5 apply to the type of range of groove types,, groove details, welding parameters, e.g., voltage range, amperage range, etc. that is qualified by the test that passed. Even if you violate a restriction listed in Table 3.7, no big deal, they don't apply to a WPS qualified by testing. If you weld in the vertical position using a 4 inch wide weave, 3/4 inch thick, you have proven it works. You are then free to use it in production.

As for what information is recorded, the codes list the minimum information that must be recorded on the PQR. Personally, I record all the code required information plus anything I believe is germane to what I am trying to demonstrate. If my goal is to demonstrate I can deposit a 4 inch wide weave, I better record that on my PQR. If I'm demonstrating I can deposit a layer that is 3/4 inch thick, I will be well served to record the thickness of each weld layer. If I want to demonstrate I can weld with water soaked electrode, I better record how long the electrode was submerged underwater before being used to weld the test sample.

I typically record the welding parameters for each weld bead deposited, the number of beads per layer, which side of the joint they were deposited on, the heat input, the interpass temperature of each bead just before initiating the arc, etc. Is it all required to meet the minimum code requirements? No, not all the information is required. Some people might consider it to be overkill, but at the end of the day I can tell you exactly what was done, bead by bead, layer by layer and the results can be reproduced if challenged.

Best regards - Al

theoretic only!!!!)?

theoretic only!!!!)?

!

!