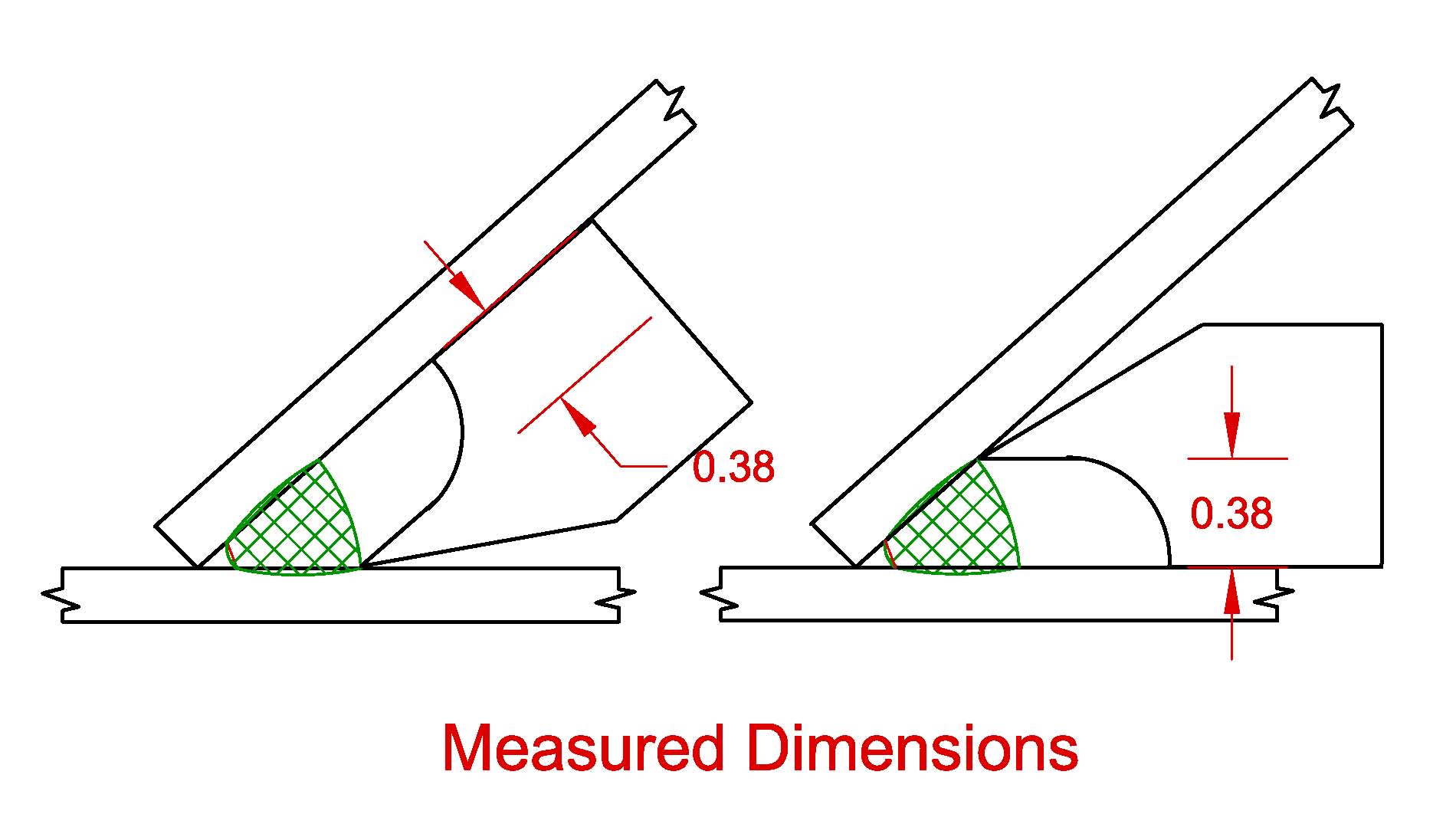

We just send out a bid, and I had the drawing guy break out any fillet that was not 90 deg in a detail. We put about 5 dimensions on the detail, just so the fabricator would not have to guess at ANYTHING. Then we told the guy in out kickoff meeting "look at these pictures and tell me what you dont' understand" He said he was fine, and I told him

"OK, if you mess this up, it's on you, you will have to build a new one for free." He didn't blink, so I gotta figure he nderstands all he needs to.