If the weld is in the joint it is a groove weld. If it is on the joint it is a fillet weld. The skewed joint is neither a groove nor a fillet. It is handled differently, thus in Clause 2 they have several subclauses that specifically address skewed joints.

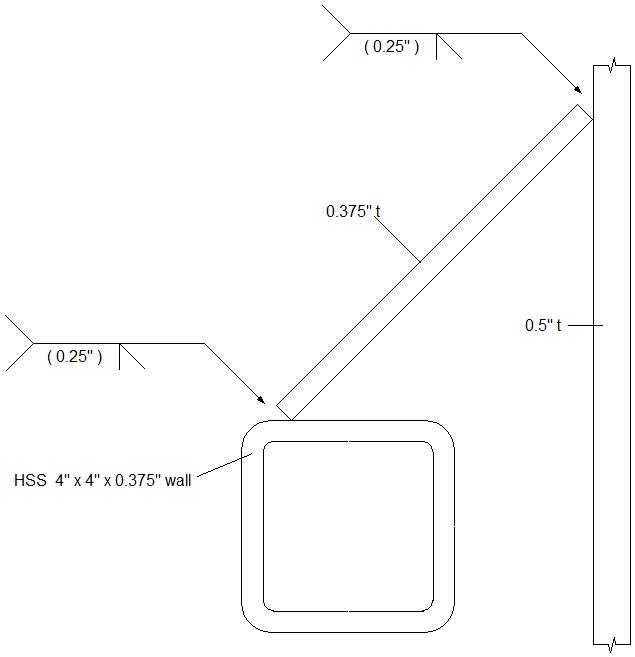

Looking at the sketch you embedded in your post, I would be inclined to call this a partial joint penetration groove weld. The weld is situated at the end of the plate or the bar and the groove angle is dependent on the joint geometry. The weld size, within the brackets, indicates the weld size required. If this is a takeoff from an S drawing provided by the Engineer, the information is sufficient. If it is from a detailer it should have provided additional information.

The basis of calling this a partial joint penetration groove weld is that this configuration is no different than a beam flange welded to a column flange, i.e., a moment connection. In this case the flanges do not intersect at 90 degrees, they intersect at something other than 90 degrees and the bevel angle is dependent on the joint geometry. As long as the angle conforms to one of the prequalified joint details for a single bevel PJP, all is well in the “land of welding”. Looking through the sketches for prequalified groove details: BTC-P4-GF or BTC-P4 can have a groove angle as small as 40 degrees in the “as fit up” condition. Notes J and K indicate the orientation of the members can be at other than 90 degrees. (looking at D1.1:2008)

If you are working to D17.1, good luck. They don't have the finesse of D1.1. The joint details are more applicable to sheet metal than structural shapes.

Best regards – Al