Okay so, this is now going to become a mixing session...

I believe that by looking @ the question again we can come up with a definitive answer for your student if we take what is relevant information from Larry's answer as well as what Al has posted and the "stuff" I just posted along with what I'll also post that's new from my original post... In other words, every one has contributed to the answer below in one form or another.

AC GTAW operations on aluminum are thought to require superimposed High Frequency (HF) in order to avoid rectification, assuming a sine wave or traditional transformer square wave power supply is being used... However those same power supplies can peform AC SMAW operations seemingly without rectification or HF. This is true because we can observe it; but why?Okay so let's break the question down to this:

1.)

AC (TIG) GTAW of Aluminum: is one process but the question is concerning a different yet similar in that it is also a constant current welding process which is SMAW...

2.)

Are thought to require superimposed High Frequency (HF) in order to avoid rectification, assuming a sine wave or traditional transformer square wave power supply... A Miller syncrowave falls into the traditional transformer square wave power supply type of power source...

3.) However those same power supplies can peform AC SMAW operations seemingly without rectification or HF.

This is true because we can observe it; but why?So before I try to narrow this part of the question down or rather clarify/simplify it somewhat, It would have been most helpful if the base/parent metal were also included as part of the query in order to avoid any confusion as to what material was being used when the student observed the AC SMAW(MMA) operations... I believe most of us assumed that the student was referring to carbon steel as opposed to Aluminum (I really do not find any joy using that word!)...Now that we broke down the question, let's look at it closer... Generally speaking, why does AC MMA/SMAW not require superimposed HF in order to avoid rectification with a traditional transformer square wave power supply and what prevents the arc from extinguishing?The first part of the answer would be because;

1.)AC MMA/SMAW is a different constant current welding process, and yet it can still be produced from the same power source as the one which produces an AC TIG GTAW process with the addition of a superimposed HF in order to avoid rectification such as a Miller syncrowave.

2.) Most SMAW electrodes contain cellulose or metal carbonates that disassociate in the arc, forming a gas shield to protect the weld metal from atmospheric contamination.

This shield consists primarily of the active gases, carbon dioxide, carbon monoxide, hydrogen, and oxygen.

These gases do not develop a highly conductive arc plasma. The current distribution is such that the liquid metal is forced away from the arc and weld pool in massive drops and spatter. Because these reactions are more intense when the electrode is negative, DC reverse polarity is generally used with the covered electrodes that do not contain cathode stabilizers within the flux coating such as E6010, E7015.

Even though this paragraph isn't directly relevant to answering the question, it is important to note some of the flux coating ingredients/Coverings shown and each of their purposes...

Coverings are intended to make the electrode thermionic (electrons emitted from materials at high temperatures). Rutile, Lime, and Iron oxide are generally used in combination for this purpose.Such electrodes produce a more stable arc, less spatter, and form smaller drops with direct current electrode negative. Included in this type are the E6012, E6020, and the high iron powder varieties...

This next paragraph explains what keeps the arc on and reigniting!The stability of the arcs with AC is dependent upon reignition of the arc during the interval when polarity is changed and the current has been reduced to zero.Stability frequency is achieved by substituting Potassium Silicate for Sodium Silicate. The potassium forms a lower ionization path between the electrode and work and increases the cathode emissivity to permit an easy reignition of the arc. Electrodes containing large amounts of Rutile and Lime are also Thermionic and do not require a potassium silicate binder for AC welding. AWS Welding Handbook 8th edition, volume 1 Welding technology, Physics of Welding, page 54, Shielded Metal Arc.

So Larry, I think the paragraph above covers this;

"2) AC SMAW has been blasting away practically since alternating current and wire first met. with no need for any kind of help." except in making sure that the correct electrodes are being used that have the desired ingredients within the flux coatings

.

#1 is already answered above!

3.) Switch the HF switch off and Voila! One can still produce an arc using AC current.

3.) Switch the HF switch off and Voila! One can still produce an arc using AC current.So all of that other stuff was nothing more than filler and not relevant to the query from Larry's student. Right??? No, not really... But one has to note as "electrode" did, that the amount of confusion one can encounter when initially observing the entireity of this thread, one can come to the conclusion that information overload is very prevalent here and confusion reigns supreme!!! So I would venture to claim that the answer is found when

1.) one considers the type of power source and how it is configured, 2.) the type of ingredients found in the flux coating covering the electrodes, 3.) the current required to start the arc, 4.) and the process being used, 5.) along with the skill level of the welder. Finally, I leave you with this from The Procedure Handbook of Arc Welding from Lincoln Electric, Fourteenth Edition, 5.1-2, Welding Processes, Principles of Operation.When electric arc welding was first developed, bare mild steel electrodes were used.

it was not only difficult to weld with bare electrodes because the arc was erratic but the weld deposit contained high levels of porosity, oxides and nitrides from reaction with the air. As may be expected, these welds lacked ductility and toughness. An essential feature of the electrode used in the shielded metal arc process is a covering or coating, applied to the core metal by extrusion or dipping, that contains ingredients to shield the arc and protect the hot metal from chemical reaction with constituents of the atmosphere.

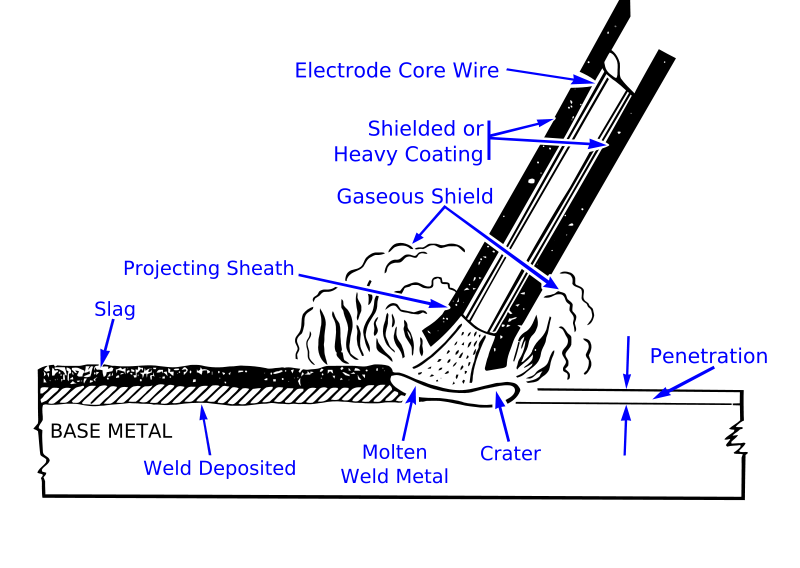

The shielding ingredients have several functions. One is to shield the arc by providing a dense, impenetrable envelope of vapor or gas around the arc and the molten metal. This is necessary to prevent the pick up of oxygen and nitrogen and the chemical reaction of oxides and nitrides in the weld pool. Another is to provide scavengers and deoxidizers to refine the weld metal. A third is to produce a molten slag coating over molten globules of metal during their transfer through the arc stream. The molten slag floats on the surface of the weld pool because it is of lower density than the metal and solidifies after the weld metal. Fig 5.1 illustrates the decomposition of an electrode covering and the manner in which the arc stream and weld metal are shielded from the air. Edit: The illustration below should suffice for Figure 5.1 I think.

Another function of the shield is to provide the ionization needed for AC Welding. With alternating current, the arc goes out 120 times per second. for it to be reignited every time it goes out, an electrically conductive path must be maintained in the arc stream. Potassium compounds in the electrode covering provide ionized gaseous particles that remain ionized during the fraction of a second that the arc is extinguished with AC cycle reversal. An electrical path for reignition of the arc is thus maintained.

Another function of the shield is to provide the ionization needed for AC Welding. With alternating current, the arc goes out 120 times per second. for it to be reignited every time it goes out, an electrically conductive path must be maintained in the arc stream. Potassium compounds in the electrode covering provide ionized gaseous particles that remain ionized during the fraction of a second that the arc is extinguished with AC cycle reversal. An electrical path for reignition of the arc is thus maintained. I'm tired so let me go lay down for a few winks and then I'll wait for a response.

Respectfully,

Hen

ry

. #1 is already answered above!

. #1 is already answered above!

ry

ry