When I worked for the equipment dealer in the field we used a 7018, in the shop an er70-s with the trigger welder. Doing shanks on big buckets with the mig was so much faster as they have 10 pounds of filler on them! Did many a backhoe bucket shank with 7018. Bigger buckets like what would be a Cat 325, 350 or bigger and preferred the wire if available. I did rental equipment with the same filler and they never broke off one of my repairs and those rental guys are some rough characters when it comes to equipment care.

Thanks. Couldn't remember, it's been 15-20 yrs since I did one. But I am not getting any older either lol

Tom

PS Nice pic's on the tower. I would love it up there. Yea man

I guess you're talking of excavators' buckets. Excavators' buckets are made of special alloy steel that has undergone more than one heat treatment.

With all due respect to Cummins' opinion, I strongly suggest you to get in contact with the bucket manufacturer and ask for his reccomendation. He knows better than anybody else the steel he used to make the bucket and its weldability.

If you read carefully Cummins' answer, he says that "when he worked for the equipment dealer ...........". So, the reccomendation he's giving you is the one the manufacturer followed to repair the buckets he made either on the field or the shop. The manufacturer of your bucket may give you a different reccomendation.

Giovanni S. Crisi

Sao Paulo - Brazil

By welderbrent

By welderbrent  Date

Date 02-06-2013 18:27

Edited 02-06-2013 18:30

I agree. I have for some applications used 8018 but most of the time it was 7018 or Dual Shield 71. I do like to use a little pre-heat on them. The shanks tend to be sensitive to cracking in cooler weather especially with no pre-heat.

The Professor is correct as well, if you really want to be sure, find out what the material is. Most smaller backhoes, trackhoes, landscaper tractors are using standard grade steels anymore. But, if you are talking about one of the BIG boys then they can easily be using T1 and/or other higher strength material which will require the 8018 and/or other procedures.

Have a Great Day, Brent

I used to fit and weld excavator buckets for a living. Ours were T-1 steel for all the leading / cutting edges and wear bars, and mild steel for everything else - best I can remember.

We used E70T-1 for all production work, with preheat when welding to the T-1, when welding the tooth adapters, and when welding in or on the 4140 bushings.

To the OP, if your building buckets as a manufacturer all the advise above is good advise. Preheat, T-1, fancy rod etc. If your doing field work and some bloke calls and says his bucket is broke and needs it fixed quick, fast and in a hurry, then break out the trusty 7018. They will not want to hear, "I have to call the factory for welding recommendations", "suggested filler metal". Much respect to the others as they are absolutely correct, but the cheap arse contractor with the broke bucket want's it fixed, making money. Things like that I will not warranty, tell them I can do it the right way or get it fixed. Besides, guys like that can destroy an anvil with a pocket full of toothpicks so even done properly I won't warranty it. Why would I? They destroyed the original bucket.

Good answer! You know you have upset all the CWIs and instructors, not to mention all the shop/rig owners who try to make a living by making everything sound a whole lot more complicated than necessary!

LOL not me. Been there and Done THAT!!! I buy off everything. All joking aside I find it funny who these people (members) of this forum are either scared to go to work or are afraid of the litigation. I am not saying all but I see alot that in the back of my head I say " Sh-- or get off the pot"

I have not been without a job for the 13yrs I have done this. Some years better than others. BUT always had a JOB.

The success of bucket repair from my observations has been more technique than filler metal selection.

It's more of an art (like flame straightening steel) than rigid procedure. Knowing how much weld (and preheat) to put where and when is going to determine a lot.

Also, cascading the beads and blending the final profile helps along with not putting more down than was necessary in the first place.

When you are maintenance in a mine and repair the same machines every week after week, you find some welders have a better track record than others. Follow their lead and learn. We welded with Innershield NR211 on 3" thick T1 and it worked just fine if you did your part. I think some welders could fix a 120 yard Dragline bucket with E6011 and the repair would hold better than others using high dollar dual shield.

Litigation is serious stuff. I know one Inspector that ate a 240gr. 44mag for a midnight snack because of bad QC calls, as in UNETHICAL not based on code and company specs. He was going to loose everything (and he HAD A LOT!) plus go to the State Pen. Being a former cop, the welcome wagon was already jazzed up for his arrival.

I am guilty of that. I would do my best to make the bead profile on the shank look like the factory welds in how they were stacked, etc. Cold weather preheat on the metal, guilty.

Howdy guys,

Finished the shank, customer picked it up this morning. He just called and asked if I could fix the other outside shank, they broke it. Love it!!! I preheated it to 350 f and used 7018 stringer beads. 17 beads total.

Thanks for all of your input, I appreciate it

The other thing to do is work over the final cap with the ball side of a ball peen hammer to spread out the metal just a little bit and will help post weld cracking.

Good to hear you got more work.

There is money to be made in Crack!

Ok plenty of VALID input.

A two yard bucket emergency repair (+ dozer blades, arms pivots then cracks on trackhoe arms, pivots buckets, stay points etc etc etc.) Yep you will do all of these in the field with lohy and a prodigious amount of preheat if your smart. Shanks in small buckets the same thing. Shanks in big buckets (8yd and up), you might want to adopt some procedures. Yea I walked away from it and it worked for as long as I cared......is a far cry from I repaired it as spec and nobody *****ed at me. Factory repairs of the truly expensive equipment will dwarf your hourly charges even when you "think" your making bank. You can make decent money or you can be liable for jackass repairs...that is your and your customers choice.

It's known as Peening from the Blacksmith Trade.

Depending on which way you are moving the metal you use a Ball Peen, Cross Peen or Straight Peen Hammer.

Not to be confused with PINKING, which is what you are likely to hear when adequate preheat wasn't applied, oxides and carbon were left in a gouge, or a gouge was made with too narrow of a groove angle.

I know what it's called, pardon the grammer mistake, sounds to me like we get some on here that can tell ya how to do it but cant do it or have never done it. Depending on the thickness of the material (T1) (AR) will determine the amount of preheat and use a 11018 filler.

I've built many buckets, large ones up to 39 yards. we never used 11018 filler. always E71T wire. The T1/AR plate is used for abrasion resistance, The welds do not need to be made with E110. Toe peening helps, especially around the teeth on the lip. Preheat is very important to prevent cracks, which can occur days after the welding.

So how many hours should it take to replace, cut off and weld a new outside shank on? I carbon arc'd the old one off.

Yeah that's true but, I have done it and done it a lot on submarine hulls and their interior & ballast tanks Boat loads of peening son!

I have also heard pinging - have you?

Henry

Pinging - heard that often when I ran regular gas in My GTO...

Here we go again!

Henry is this your latest fad?

By ssbn727

By ssbn727  Date

Date 02-11-2013 05:49

Edited 02-11-2013 05:53

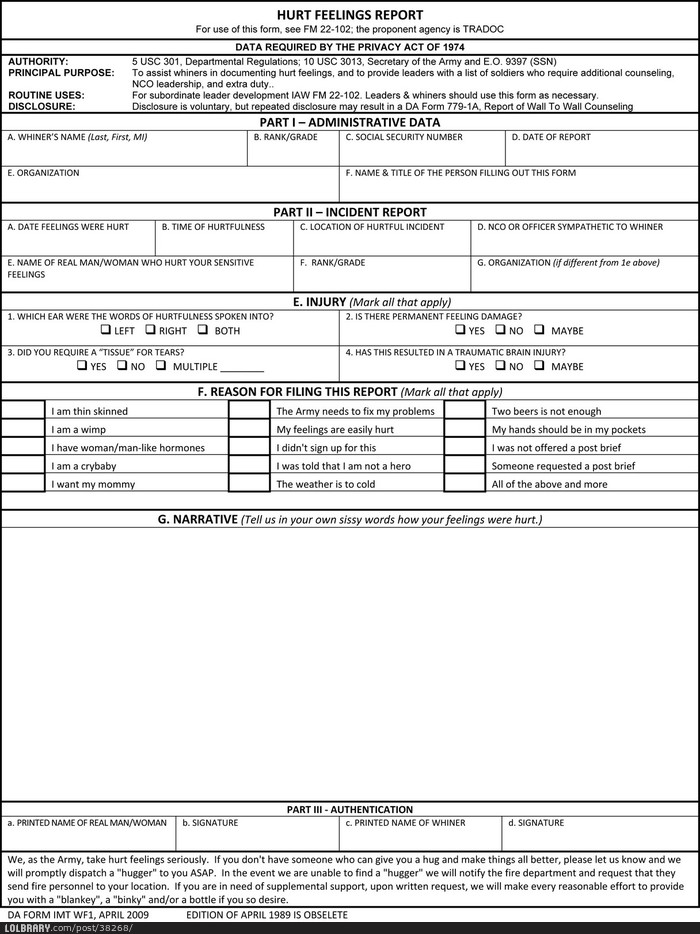

Pretty official looking eh?

Feel free to use it Glynn!

No fads allowed now by the self imposed moderator! HaHaHa!!!! What R U a cop???

Don't forget to fill it out completely now and sign it when you're finished

Thanks Dave,

I forgot about that example... What year was your Goat???

Respectfully,

Henry

Is this Form gunna be brought up every time someone disagrees with you Henry?

At least we seem to have lost the emoticons, that's promising at least!

Guess it does, sorry about the return of the emoticons though, I thought the forum was a better place without them.

OK but your getting pretty boring now!

how many hours should it take to remove with carbon arc and replace with new one?

I had a '69 that I drove regularly, another '69 that was going to be a street/strip car, but the '79 gas crunch ended that, and a '68 parts car.

The '69 that I drove was a real plane Jane, factory 3 speed, manual steering & manual drum brakes with the standard WT 350HP 400" engine & 3.55:1 rear end. It did have the hood tach. I later put the 4 speed out of one of the other ones in it, didn't change performance 1 iota. The posi in this one was shot, should have swapped the one from the '68.

The other '69 had more optional equipment, I got it with a hopped up but not running motor.

The '68 was really rusted out badly and the motor was blown.

Good Morning;

From an old movie: " Verify the distance; one ping only".

The Hunt for Red October. Pretty good movie.

Also; Ping was the knock off the the seventies game Pong. Shorter paddles. I am not sure about that one.

I always enjoy reading your posts and from reading them for a while, I am glad you are feeling up to posting again.

Have a good day;

Matt

Personally I associate PINGING with the M1 Garand.

Old "Blood & Guts" General George S. Patton gave very high praise when he described the M1 Garand with this quote: "the greatest battle implement ever devised."

Ejection of an empty clip created a distinctive metallic "pinging" sound. In World War II, reports arose in which German and Japanese infantry were making use of this noise in combat to alert them to an empty M1 rifle in order to 'get the drop' on their American enemies. The information was taken seriously enough that U.S. Army's Aberdeen Proving Ground began experiments with clips made of various plastics in order to soften the sound, though no improved clips were ever adopted. According to former German soldiers, the sound was inaudible during engagements and not particularly useful when heard, as other squad members might have been nearby ready to fire.

Rumors!

Respectfully,

Henry

Thanks Unclematt!

How's your health coming along?

Respectfully,

Henry

Hello Henry;

Guess I am doing as well as I can. Went and seen the doc Thursday and he said it will be two months until we know for sure if it took or not. Even then he said I won't be all the way back to 100%. I kinda figured that. I messed up the other day and threw a bag of trash in the back of the truck. I sure knew I wasn't ready when I felt a pull from my neck to my shoulder. Wife threatened to whip me so I am not gonna do it again. I hope your health is improving and things are well.

Have a good one;

Matt

By Superflux

By Superflux  Date

Date 02-11-2013 15:06

Edited 02-11-2013 15:52

I've built Esco buckets up 124 cubic yards and also spent 6 years in Coal and Gold mine maintenance and construction.

We never welded buckets with 11018 (either 70 or 80 ksi filler) but did peen a lot of welds.

Some oldtimers used to think that metal had to be preheated 100°F per inch of thickness, but this not the case. While building a 38 yd shovel bucket for the Iron Range, I had to stop a shop Inspector (NOT! a CWI) who was going to make the welders preheat 6" thick ASTM 514 using this ridiculous rule.

Most procedures for T1 (ASTM 514) call for 250°F preheat with a 350° maximum innerpass.

Always the way to go "SMOKES YOUR COMPETITION " (had a newbie welder complain to me once that I was" ruining the welding trade" because we use wire feed on this type of work)!!!!!!! Once again IT'S ALL ABOUT THE DOLLARS!!!!!!

Always the way to go "SMOKES YOUR COMPETITION " (had a newbie welder complain to me once that I was" ruining the welding trade" because we use wire feed on this type of work)!!!!!!! Once again IT'S ALL ABOUT THE DOLLARS!!!!!!

$$$$$$$$$$$

$$$$$$$$$$$