Re-heat of what? Are we talking low hydrogen welding electrodes? Are we talking about...???

At least for myself, a little more information would be good.

Have a Great Day, Brent

Hi Edisonwang,

I can't open your link (security block), but I can give you pointers.

There are two methods for calculating preheat of base metals.

a) HAZ Hardness Method. Based on the assumption that cracking will not occur, in the HAZ, if the hardness of the HAZ is kept below a critical value. Also known as the Isothermal Trasformation Method. Minimizing the HAZ hardness is achieved by controlling the cooling rate. The critical cooling rate for a given hardness can be related to the carbon equivalent of the steel. From the critical cooling rate, a minimum preheat temperature can be calculated. Its main value is in determining the minimum heat input (and hence minimum weld size that prevents excessive hardening).

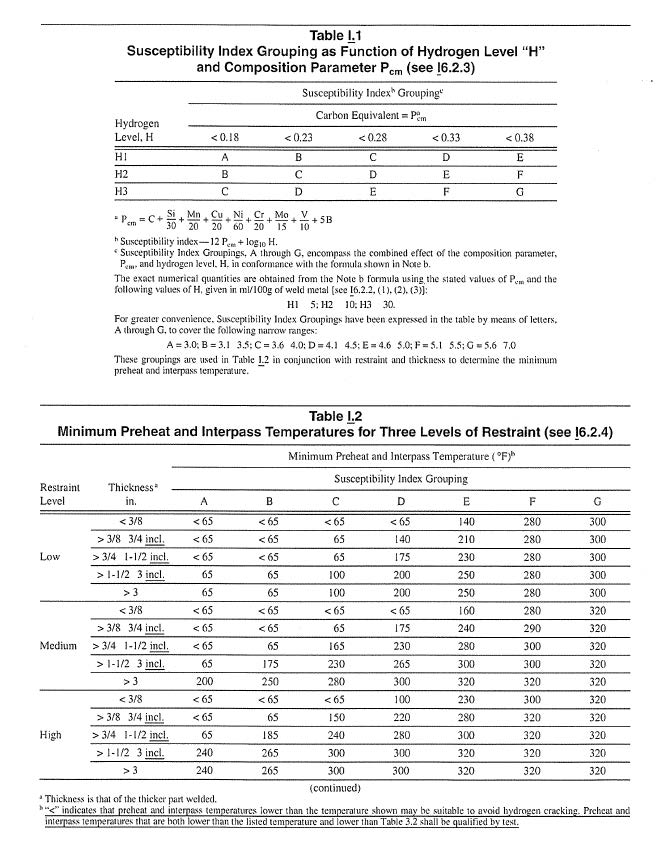

b) Hydrogen Control Method. Based on the assumption that cracking will not occur if the amount of hydrogen remaining in the joint after it has cooled to 120˚F does not exceed a critical value. Also known as the Temperature Control Method. This method is most widely used since the inputs to the calculations are readily available.

Either method is acceptable but I think the Hydrogen Control Method is quicker and a lot cheaper to perform. There are a few different tools to calculate the Hydrogen Control Method, here are some: AWS, Canadian Welding Bureau (CWB) Calculator, The Welding Institiute (UK), Lincoln Electric Preheat Calculator....

Good luck

Tyrone