The key is "...will develop the adjacent base metal strength in tension and shear."

The next step is deciding what is the most economical means of developing the required strength. The designer can use a CJP, a PJP, fillet welds, or a combination of CJP or PJP and fillet welds.

Consider the allowable stresses assigned to the weld types per Table 2.3. Simplifying the requirements: the CJP weld can be assigned the same allowable stresses as the base metal when loaded in tension or shear. However, the PJP is only permitted a fraction of the stress, so the weld size is roughly three times larder. Likewise for the fillet weld. Both the PJP and the fillet welds have built in "cracks" in the weld root where there is incomplete penetration in the case of the groove weld or incomplete fusion in the case of the fillet weld. Both conditions represent notch-like stress risers that concentrate the stress in the weld root and enhances the probability of initiating a crack.

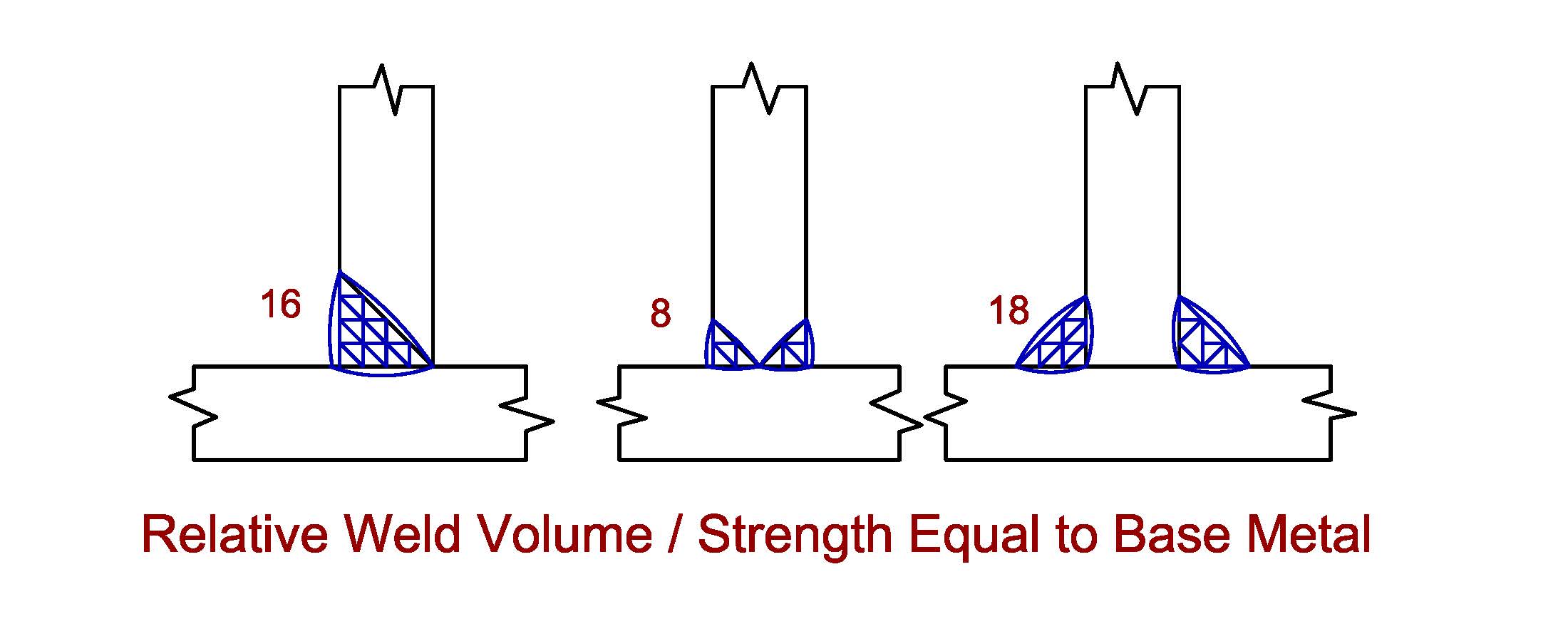

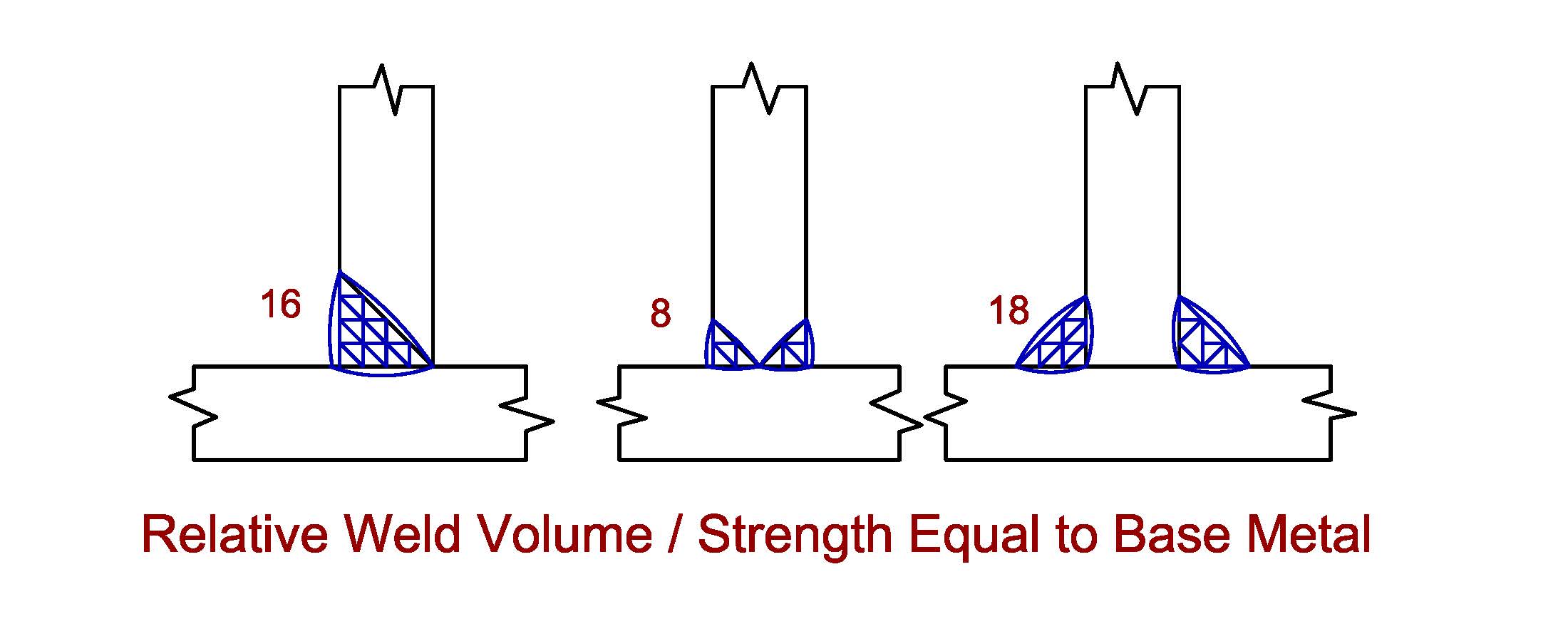

Back to the economics of the situation: assuming you have a 1 inch thick plate of ASTM A36 used to fabricate a T-joint. The required fillet size needed to develop the tensile strength and shear strength of the butting member, double fillet welds measuring 3/4 times the thickness of the plate is required. the area of the double fillet weld is about 1 square inch. Compare that to a CJP groove weld using a 45 degree groove angle of 1/2 square inch. Which requires less weld? Which is the most economical? It is simple economics. The volume of the CJP is reduced even further if double groove welds are used.

So, you are correct, the choice is up to the designer. CJP, PJP, or fillets, as long as the loads are transferred from one member to the next, all is good when the Engineer is not specific as to the weld type required. The sketch compares the relative volume of weld metal for a CJP single bevel, CJP double bevel, and double fillet welds. What I didn't get into is the relative volume required for PJP double bevel grooves. I suspect the relative volume would be the same as the double fillet welds.

Best regards - Al

Al,

Very helpful explanation, thanks. To make sure I'm understanding correctly: any of the possible weldments are able to achieve the required strength in your 1" plate T configuration and the volume of the deposits would be a determining factor in the economics of its production.

If so, then in the case where a CPJ is not specifically called out, the fabricator would need to decide whether a CPJ requiring more joint preparation and possibly more skill to produce was more economical than a larger sized fillet or PJP.

Inspection criteria and potential repair rates/difficulties would need to factor in as well I would think. Given the OPs configuration I wouldn't want to have to consider any repairs to the inner side of either of the welds, would be a bear to get at them. I am not clear if there are different inspection criteria for fillets vs. CJPs or PJPs. The overwhelming majority of my CJP welding has always been on pipe to either ASME or API but as a welder I've always just treated them the same, ie. make sure they're 100% clean and don't look back. My impression has always been that a CPJ was inspected to a more stringent criteria, which if true [and I have no substantiated reason or code reference to hold this opinion] that a fillet or PJP might not be the way I would want to go.

Could you respond to the relative stringency of the inspection criteria?

By 803056

By 803056  Date

Date 07-29-2014 18:24

Edited 07-29-2014 20:37

I didn't say the welding symbol has to call for a CJP in the tail. The applicable code may take a stance on the subject as does AWS D1.1. AWS A2.4 basically takes the position that a welding symbol that doesn't list a depth of bevel and a weld size is by default a CJP.

AWS D1.1 differentiates between a contract drawing and a shop drawing. The shop drawing must show the required details. The contract drawing leaves the contractor latitude to select a specific groove detail.

Again, the code must be consulted regarding the need for different acceptance criteria or the extent of inspection for CJP, PJP, or fillet welds. AWS D1.1 makes not distinction between the weld type except in the case of certain connections subject to specific fatigue loads.

Best regards - Al