Simple, ask him or her (the Supervisor) to show you where it states this and also the limits etc. in the current or even the stipulated version of D1.6...

TBH, it usually works the other wise around but since you and the TPI seem to be at a loss, use there weapons against them!

Mike,

WELCOME TO THE AWS WELDING FORUM!!

Fabricator/erector supervisors are more interested with production and will bend every rule and push your buttons to make as much profit on the job as possible. Some just like to argue, especially in front of their crew, to show that they are the authority and you know nothing and are nothing on the job. Be very careful about these situations and don't let them push you into a public showdown regardless of who may be right.

For the most part I concur with Joey, check your drawings and/or contract documents FIRST. In order to do that you must know one other item, what does the applicable code say is the engineer's responsibility for calling out weld sizes? Now, not having D1.6 handy I am going to reference D1.1-2010. In Clause 2.3.4 we are told it is the engineer's responsibility to call out weld sizes and for fillet welds that means the leg size. So, in a drawing for items being built to D1.1 I am to examine the fillet welds based upon this information, leg size rules the day. So my drawing calls out a 5/16" fillet weld. That means it is to be a 5/16" leg dimension from the root out and assumes the qualified welder has gotten penetration at least TO the root but not necessarily beyond. Not my job on production welds to challenge that assumption, it is established by the committee on D1.1 as a starting place and is the why behind all the preliminary paperwork on welder quals, MTR's, and WPS's. If all things are followed then the ODDS are in our favor and the weld is what it is supposed to be.

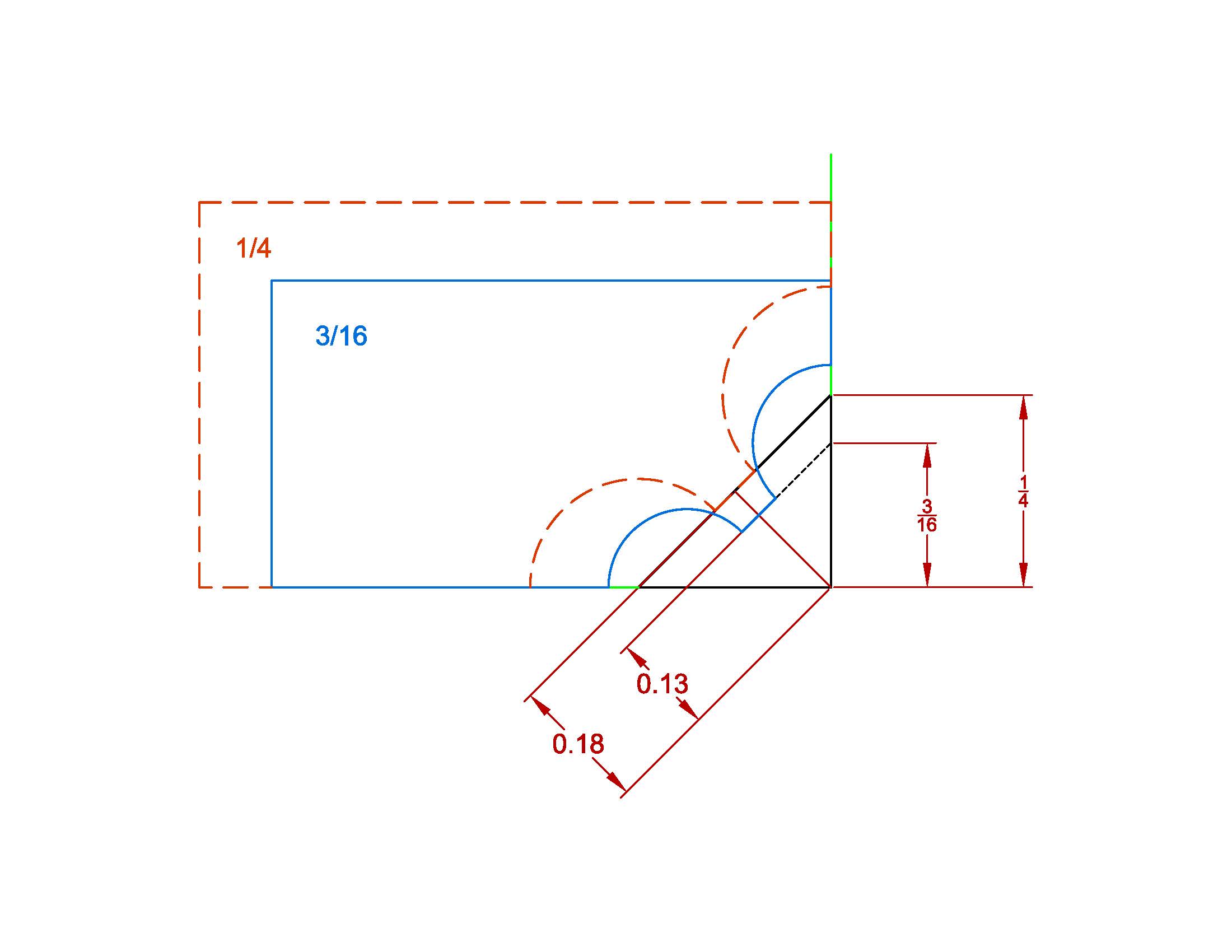

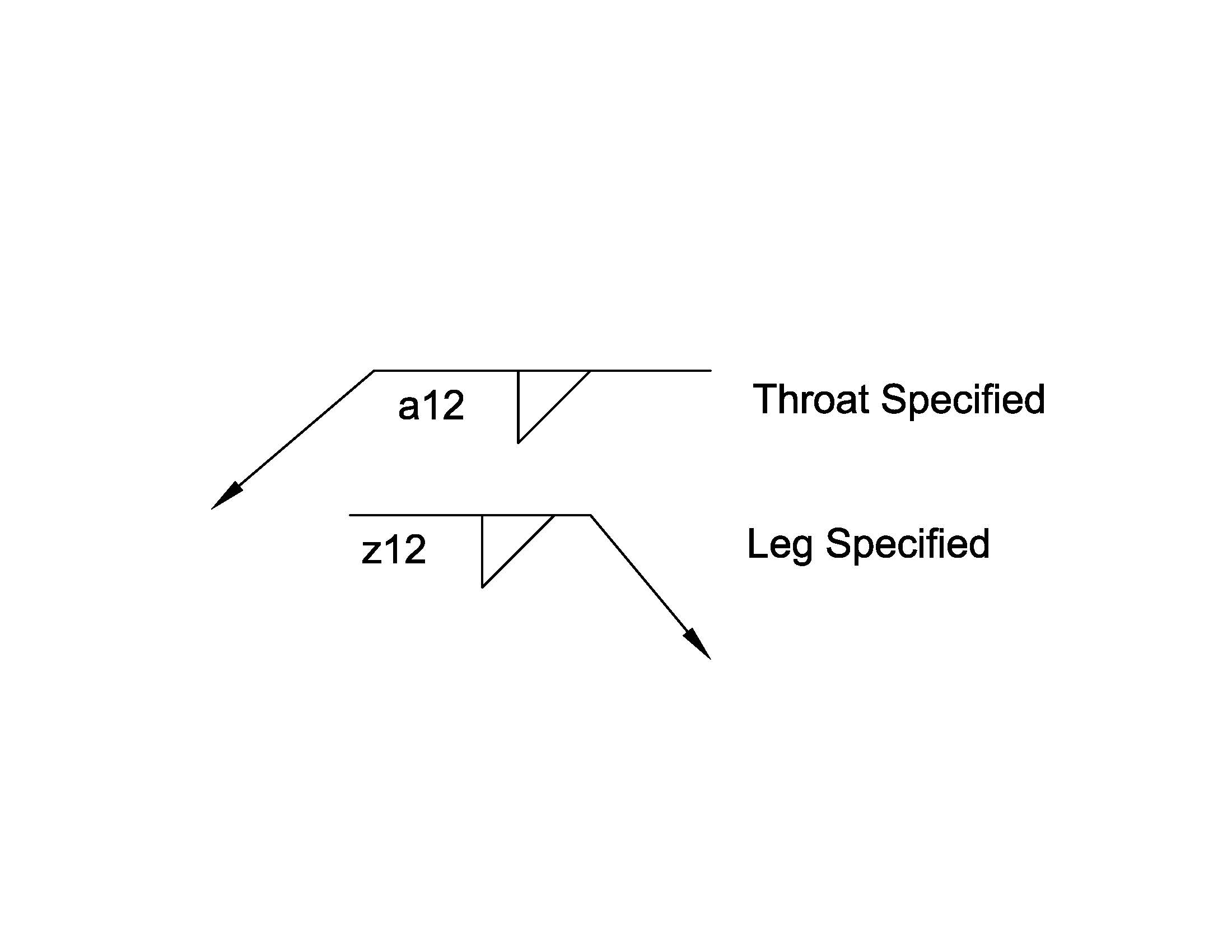

So, having a drawing specified fillet weld with leg dimension of 5/16" I grab my 5/16" fillet weld gauge. It has two ends, one for convex which is measured by the leg size, and one for concave which is measured by the throat. The throat is not actually 5/16". It is properly calculated for the inspector to be the proper throat for a 5/16" leg fillet weld, approx .222".

Fillet weld gauges are go/no-go gauges, it either meets the specified size or it does not. There is no middle ground. Now, most codes will allow some underrun. You need to know what that is for your job. Again, drawing notes/contract documents and applicable code. But, while underrun is established using the leg dimension, it then is proportional for the throat. If you can be acceptable with a 1/4" weld leg, then the 1/4" throat would be acceptable, for a short run of the length as determined in the applicable code, NOT THE ENTIRE LENGTH OF THE WELD.

Remember as well, a concave weld is not necessarily a bad weld. Just a comment based upon your statement of "The welders are putting down terrible welds and are having a ton of concave filet welds,".

The throat is a direct ratio size with the leg dimension specified on the drawing. So, in a way, you, the TPI, and the supervisor are correct. It is all in the final application and depends upon the applicable code, the contract drawings, and the end result of properly used fillet weld gauges. Some of the welds may be acceptable and some rejectable. You must carefully determine the end status.

He Is In Control, Have a Great Day, Brent