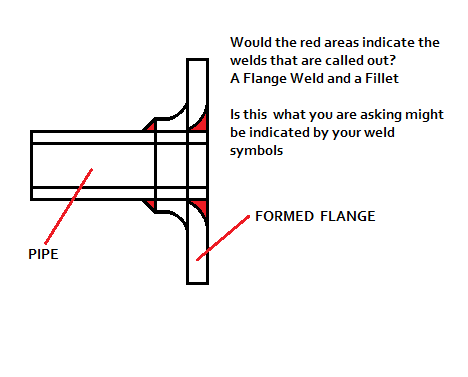

Very nice. Now we have something to work with.

Can I ask what the applicable construction code is?

AWS D1.1 includes a statement that for angles between 80 and 100 degrees, a fillet weld is or can be used. For angles between 60 and 80 degrees or for those more than 100 degrees, annex B must be consulted to calculate the "corrected" leg dimensions (my words). For angles less than 60 degrees, the Z-loss must be taken into consideration. As stated, those requirements apply to structural applications, not necessarily ASME.

ASME has an interesting approach; it is the manufacturer's responsibility to ensure the design is adequate for the application unless it is prohibited by the applicable construction code. It provides the engineer with plenty of latitude and nearly no direction. You prove it works and the sky is the limit.

Best regards - Al