I stole it.

Found it with a Google search of corner welds couldn't get some of mine to work taking them from my codes and specs on the computer.

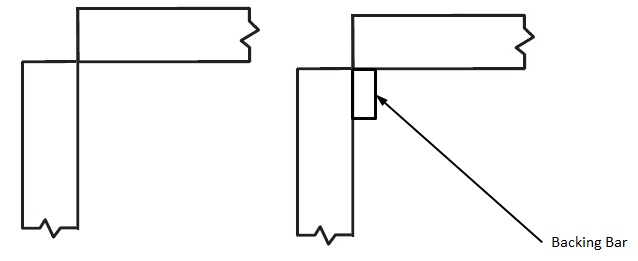

See above but it is simply a fillet weld as drawn.

See drawing attached here thanks to Al. This is a fillet weld. It is also a fillet weld when used in a 90° application as previously stated on lap and corner joints as well as T joints.

It is important to always keep 'joints' and 'welds' separated in our mind and terminology. There is no such thing as a fillet joint. There is no such thing as a corner weld, lap weld, T weld, etc.

A good reference is A3.0 Defs and Terms, and A2.4 Weld Symbols. So also the section on Weld Symbols in the WIT book (Welding Inspection Technology) available from AWS.

Brent

Found it with a Google search of corner welds couldn't get some of mine to work taking them from my codes and specs on the computer.

Found it with a Google search of corner welds couldn't get some of mine to work taking them from my codes and specs on the computer.